Contributed by Kostya S. Novoselov, February 20, 2021 (sent for review December 14, 2020; reviewed by Ricardo Garcia and Andrej Košmrlj)

Author contributions: P.A., C.R.W., L.F., and K.S.N. designed research; P.A., Y.B.W., C.R.W., J.D., L.F., F.G., and B.D. performed research; P.A., L.F., F.G., B.D., and K.S.N. analyzed data; and P.A., F.G., B.D., and K.S.N. wrote the paper.

Reviewers: R.G., Consejo Superior de Investigaciones Cientificas; and A.K., Princeton University.

Instabilities and formation of complex patterns play an extremely important role in many branches of science. Understanding the origin of instabilities is very important for many technologies. We demonstrate the formation of instabilities (radial wrinkles around bubbles) in atomically thin crystals. Two-dimensional crystals, arranged into van der Waals heterostructures, allow full control over the mechanical properties of the components and the interaction between them, making such experiments easy to reproduce and allowing one to understand the basic, underlying physics of such effects. Such heterostructures allow the observation of instabilities around structural defects (bubbles) where the crystal structure plays a significant role, providing insights into these effects. Such instabilities allow assessment of the elastic and interaction properties of the membranes.

Nonlinear mechanics of solids is an exciting field that encompasses both beautiful mathematics, such as the emergence of instabilities and the formation of complex patterns, as well as multiple applications. Two-dimensional crystals and van der Waals (vdW) heterostructures allow revisiting this field on the atomic level, allowing much finer control over the parameters and offering atomistic interpretation of experimental observations. In this work, we consider the formation of instabilities consisting of radially oriented wrinkles around mono- and few-layer “bubbles” in two-dimensional vdW heterostructures. Interestingly, the shape and wavelength of the wrinkles depend not only on the thickness of the two-dimensional crystal forming the bubble, but also on the atomistic structure of the interface between the bubble and the substrate, which can be controlled by their relative orientation. We argue that the periodic nature of these patterns emanates from an energetic balance between the resistance of the top membrane to bending, which favors large wavelength of wrinkles, and the membrane-substrate vdW attraction, which favors small wrinkle amplitude. Employing the classical “Winkler foundation” model of elasticity theory, we show that the number of radial wrinkles conveys a valuable relationship between the bending rigidity of the top membrane and the strength of the vdW interaction. Armed with this relationship, we use our data to demonstrate a nontrivial dependence of the bending rigidity on the number of layers in the top membrane, which shows two different regimes driven by slippage between the layers, and a high sensitivity of the vdW force to the alignment between the substrate and the membrane.

The extraordinary mechanical properties of two-dimensional (2D) materials have attracted considerable interest from the physics and material science communities (123–4). Such materials present a very versatile playground allowing realization of multiple modeling objects, such as the thinnest possible membranes with miniscule bending rigidity or very stiff plates, all with very reproducible parameters. Furthermore, both the electronic and mechanical properties of such crystals can be fine-tuned by assembling them into van der Waals (vdW) heterostructures (56–7), which allow realization of yet even broader range of materials parameters and boundary conditions. Of special interest are the properties of free-standing mono- and few-layer 2D crystals: membranes and bubbles (89–10). The elastic response of such systems is highly nontrivial, being governed by the vdW membrane-substrate’s attraction, the bending rigidity of 2D solid membranes, and their Young modulus. Furthermore, atomic thinness of the membranes makes it possible to switch between different regimes—from where the bending rigidity is much smaller than the Young modulus (monolayer membrane), to where they are comparable (in the case of few-layer membranes). A common outcome of this interplay is the instability of the neutrally planar state and the consequent emergence of complex wrinkle patterns when the membrane experiences minute levels of compression (1112–13). Understanding the conditions under which such instabilities emerge and spread throughout the system is of utmost importance both fundamentally and for the functionality of various vdW heterostructure devices. Specifically, the formation of wrinkling patterns is usually associated with a nontrivial strain distribution (14, 15), which, for piezoelectric 2D crystals such as MoS2 and hBN (1617–18), leads to a complex distribution of the electric field and can be used in respective devices. Furthermore, a careful analysis of the emerging patterns can be harnessed for metrological purposes—extracting valuable information on the material parameters that characterize the elastic moduli of 2D membranes and their vdW interaction with the substrate.

In this work, we study patterns of radially oriented wrinkles induced by bubbles in vdW heterostructures that consist of hexagonal boron nitride (hBN) or molybdenum disulfide (MoS2) layers on top of another 2D material. We show that the periodicity of the emerging patterns reflects a balance between the membranal bending rigidity (B) and the steepness of the vdW potential well, namely, its second derivative (), evaluated at the equilibrium value of the membrane-substrate distance (19). Although this type of balance between bending rigidity and stiffness of an “effective substrate” has been known to govern wrinkle patterns in thin polymer sheets (14, 20212223–24), the current report provides a noninvasive probe for the vdW interaction between atomically thin membranes and atomically flat substrates. Furthermore, the relative crystallographic orientation between the crystalline, atomically thin membrane and the substrate can be controlled precisely, giving us an extra knob to change the vdW interaction. Our results demonstrate that classical nonlinear mechanics of solids, which describes strain-induced elastic instabilities, can be applied (with some modifications) to the description of pattern formation in complex vdW heterostructures and provide a metrological tool for characterizing the interplay between the vdW attraction and the bending modulus of monolayers and multilayer composites.

We produced high-quality vdW heterostructures with atomically flat monocrystals of hBN on top of graphene (both in incommensurate and commensurate configurations) and MoS2 on top of hBN using the standard dry transfer technique (25). In brief, we mechanically exfoliate and identify our top 2D material on a polymer film consisting of two sacrificial layers, one of polymethylglutarimide (PMGI) and the other of poly(methyl methacrylate) (PMMA). We develop the PMGI layer from beneath the PMMA layer to create a free-standing membrane that we could easily manipulate with the crystal on top. Then we inverted the membrane and we positioned it above our substrate 2D material, which is resting on a SiO2/Si substrate, using a set of micromanipulation stages with spatial accuracy better than 5 μm and alignment precision ∼0.5° to control the twist angle. For the commensurate configuration, we aligned the crystal lattices by choosing straight edges of both top and substrate 2D crystals, which indicate the principal crystallographic directions, and brought them into contact making their edges parallel. For the incommensurate configuration, we rotated the top crystal by ∼15° with respect to the 2D substrate edges before bringing them into contact. We then removed the PMMA by simply peeling back the membrane. In such structures, bubbles of trapped substances are spontaneously formed between the substrate and the membrane, such that the membrane portion on top of the bubble is completely delaminated from the substrate. Bubbles appear when 2D crystals with high enough adhesion are brought together due to a self-cleansing mechanism (7, 26), which pushes trapped contaminants to gather into bubbles (9, 27). We imaged our samples with atomic force microscopy (AFM) (28, 29) using a dynamic mode (30, 31), so the images were taken in a gentle noninvasive way ensuring that the sample was not damaged or deformed. We found that the typical radii R of bubbles are in the range 50–300 nm, and their heights H are 10–30 nm; however, the aspect ratio H/R is constant for each given membrane thickness. This constant ratio was shown to be

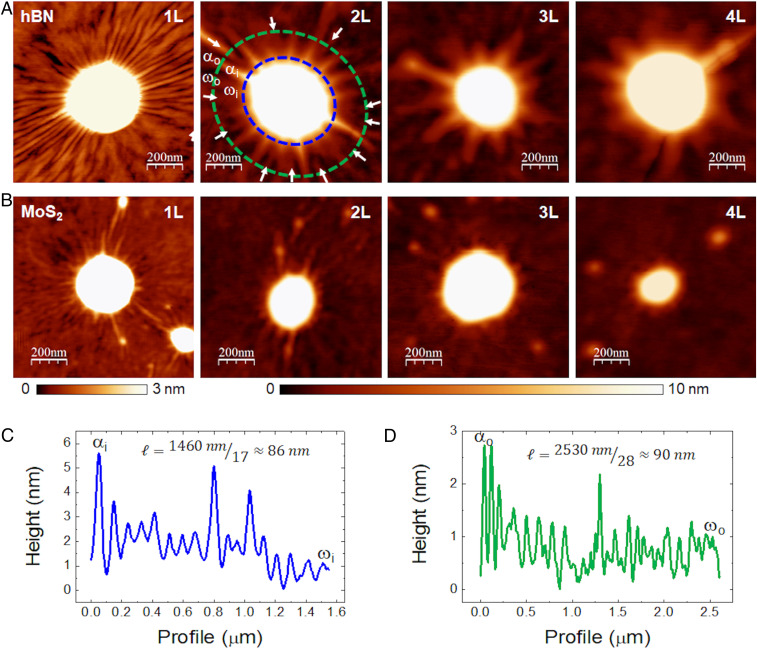

We start our analysis with the incommensurate configuration. Fig. 1 shows the development of a “corona” of wrinkles (azimuthal undulations of the shape at the laminated portion around the bubble) for membranes of different thicknesses.

Topographic images of wrinkles around bubbles hBN and MoS2 of different thicknesses. (A) Bubbles with wrinkles in hBN membranes of different thicknesses (monolayer, 1L; bilayer, 2L; trilayer, 3L; and four-layer, 4L) incommensurately stack on graphite substrate. The arrows in the 2L hBN bubble point to wrinkles that nucleate away from the bubble’s edge, such that the condition

From profiles around the topographical images of the wrinkles around the bubbles we can determine the wavelength

The mere existence of radial wrinkles is attributed to the pressure in the bubble. Rather than a uniform, isotropic surface tension (as would be for a gas-filled vesicle), such a pressure gives rise to an anisotropic stress field in the membrane, whose radial component is tensile,

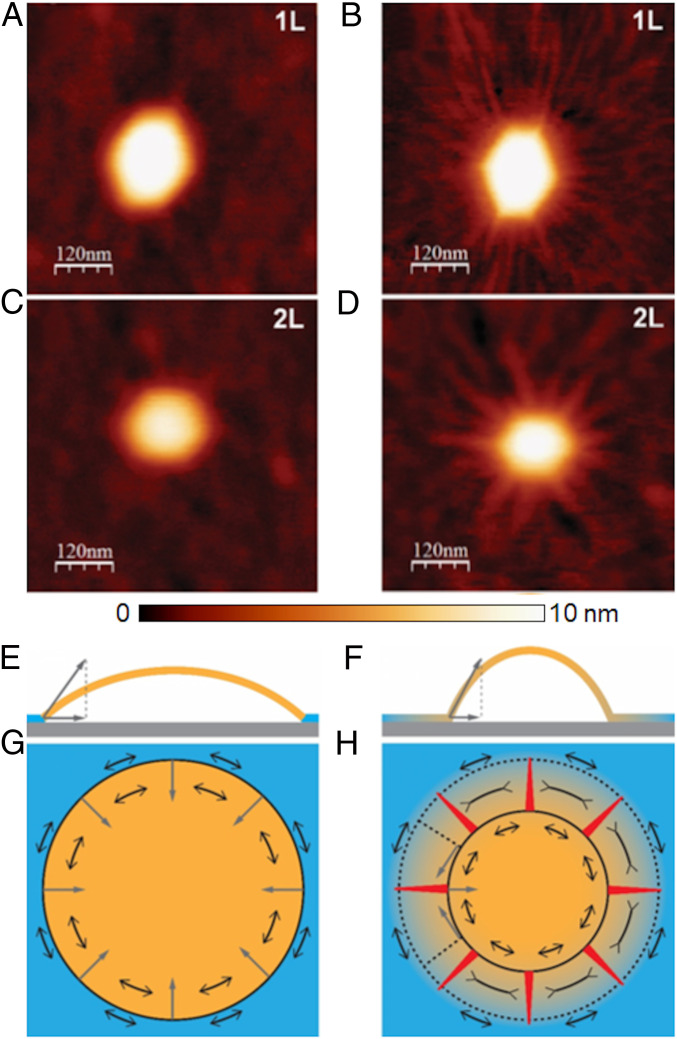

Formation of wrinkles. (A and C) Bubbles in hBN membranes of different thicknesses (A, 1L; C, 2L) incommensurately stack on graphite substrate just after fabrication. (B and D) Same bubbles as in A and C, respectively, after leaving them overnight at high humidity, where the appearance of wrinkles is clearly visible. (E and G) Side and top schematic views on the bubble without wrinkles (stress does not spread into the material in contact with the substrate). (F and H) Side and top schematic views on the bubble with wrinkles (stress spreads into the material in contact with the substrate). Shades of yellow represent the level of stress. Single-headed gray arrows represent the elastic forces acting on the perimeter of the bubble. Double-headed black arrows depict components of the stress tensor. The red triangles in H represent the wrinkles. Whereas in G the azimuthal (hoop) stress is purely tensile, in H it is tensile-compressive-tensile.

Throughout the azimuthally compressed corona of the bubble, the low bending rigidity of the membrane underlies an elastic instability, whereby the membrane seeks to deflect away from the substrate in order to suppress hoop compression and eliminate the large energetic cost it entails. If the vdW attraction were sufficiently weak, one may expect this instability to give rise to a highly nonuniform pattern, where a complete detachment from the substrate in a few narrow angular sectors enables the membrane to retain a full contact with the substrate elsewhere. Such a delamination pattern would be characterized by a small number of narrow, high-amplitude and radially oriented “folds,” separated by perfectly flat, nonundulatory zones, as was assumed in ref. 11, but in sharp contrast with our observations. Instead, the emergence of a simple periodic pattern, characterized by a single wavelength, suggests another instability mechanism, whereby the vdW attraction is sufficiently strong to resist delamination anywhere but beneath the highly pressurized bubble, and small-amplitude radial wrinkles emerge to suppress hoop compression in the corona (see schematic Fig. 3A). This phenomenon resembles the effect of a liquid drop placed on top of a floating polymer sheet, where the Laplace pressure inside the drop gives rise to preferentially radial tension in the sheet, and to the suppression of would-be hoop compression through radial wrinkles (21, 24).

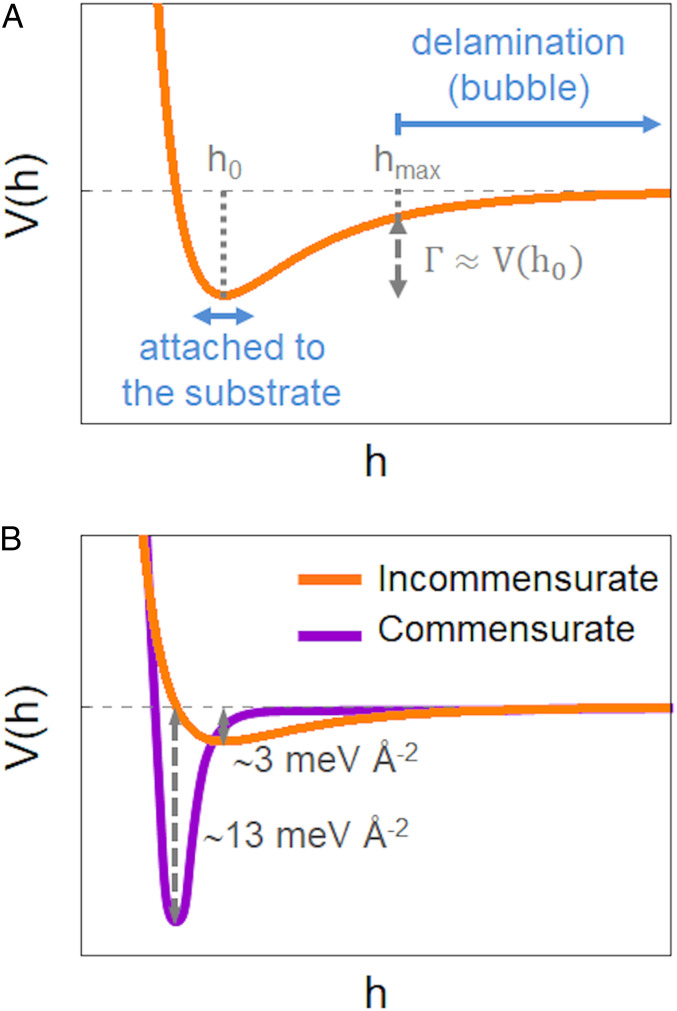

Schematic graphs of the vdW potentials. (A) Shallow vdW potential for the case of incommensurate stacking. For substrate-membrane distances above a threshold value (hmax) the vdW attraction

The typical “wavelength”

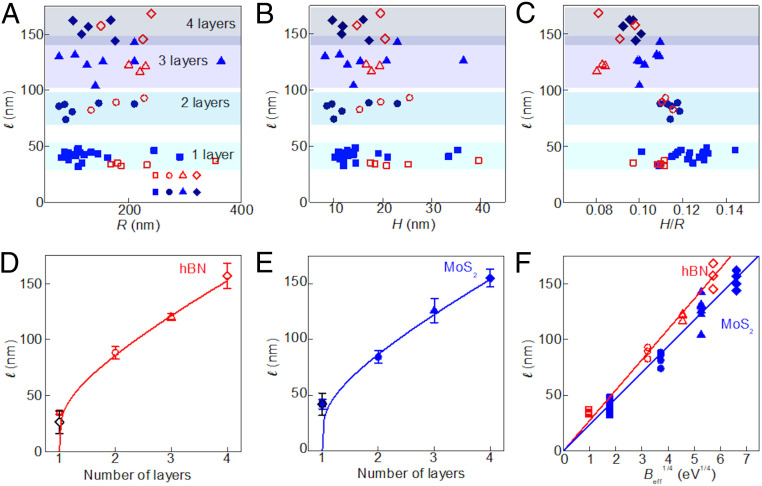

1)The number of wrinkles decreases sharply with the number of layers N.

2)The wrinkle number

3)In the vicinity of the bubble,

4)Notwithstanding their high azimuthal curvature, the amplitude of wrinkles,

5)For a given type (and number of layers) of the top membrane, the average wavelength

Wrinkle’s periodicity for hBN and MoS2 bubbles of different thicknesses. Plots of the average wrinkle wavelength as a function of: (A) bubble radius, (B) height, and (C) aspect ratio, for hBN (open red symbols) and MoS2 (solid blue symbols). Here squares are for monolayer membranes; circles, bilayer; triangles, trilayer; and rhombuses, 4-layer. (D and E) Average wavelength as a function of the number of layers (symbols) and fits to Eq. 2 (lines) where the value of

Focusing our attention on the wavelength of wrinkles, we recall a general relation, known as the “local wavelength law” (14, 23):

Having established the nature of the effective stiffness in Eq. 2, let us now address the bending modulus B. Generally, there are two regimes for the bending of multilayer 2D crystals. At low bending curvature (large

Fig. 4 D and E show the wavelength as a function of the number of layers for hBN and MoS2, respectively, and fits of the experimental points to the “local wavelength law” (Eq. 2), with substrate-dominated stiffness. For these fits, the bending rigidity has been considered as the effective bending rigidity above the crossover length from Eq. 3; thus it scales as the cube of the number of layers, making

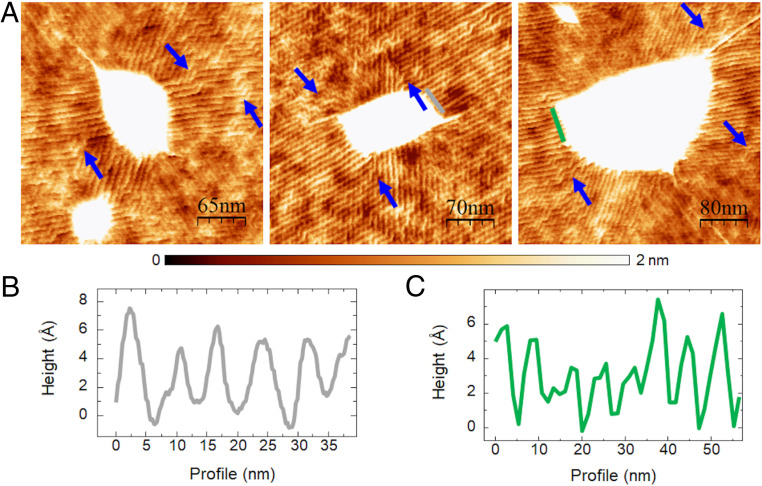

Let us turn now to commensurate configurations, where the hBN membrane is crystallographically aligned with the underlying graphene membrane. In this case, the behavior is remarkably different. Small rotation angles between the lattices of the two crystals form a periodic structure with different stacking configurations, yielding a moiré pattern (38). Fig. 5 corresponds to a monolayer of hBN aligned on top of a graphene flake presenting bubbles, as in the incommensurate states. It can be observed, however, that in the commensurate case the wrinkles exhibit a substantial deviation from radial orientation and become constrained to the moiré periodicity originated by the strong interaction between the top and the bottom layers. The wavelength of the wrinkles in this case is

Wrinkles in commensurate case. (A) Wrinkles around bubbles in commensurate heterostructures of aligned monolayer hBN on graphene. The arrows point to kinks where the wrinkles change their orientations abruptly, following the underlying moiré pattern. (B and C) Profiles along the lines in the middle (B) and right (C) panels of A. The height of the wrinkles in the commensurate cases is ∼3–6 Å.

This higher interaction is directly reflected in the aspect ratio of the bubbles. Whereas the typical H/R ratio for the incommensurate state of a monolayer hBN on graphene is 0.11 ± 0.02, for the commensurate state this value increases to H/R = 0.16 ± 0.02 (SI Appendix, Fig. S4). As mentioned in the introduction, the aspect ratio H/R is proportional to the ratio

Our experimental observations portray a nontrivial, multiscale interplay of the vdW substrate-membrane attraction, the high membranal resistance to stretching, and its low bending rigidity, driven by the presence of trapped substances between the membrane and the substrate. The primary response, which has been reported previously and is barely affected by bending rigidity, is the aggregation of trapped substances into highly pressurized bubbles of radius R, thereby causing delamination of the membrane from the substrate at r ≪ R (where h(r) > hmax) in Fig. 3, and, consequently, a large radial tension,

We thank Guillermo López-Polín for insightful discussions. We are also grateful to the reviewers for their constructive remarks. We acknowledge support from the Marie Sklodowska-Curie Actions (Grant Agreement 793394), the European Research Council through Grant Agreement 819417, and Synergy Grant Hetero2D under the European Union Horizon 2020 research and innovation program, the European Commission under the Flagship programs (Graphene Flagship Core 3, Grant 881603, and the Contract CNECTICT-604391 and 2D-SIPC Quantum Technology), Grants NMAT2D (Comunidad de Madrid, Spain), SprQuMat and SEV-2016-0686 (Ministerio de Ciencia e Innovación, Spain), the NSF under Grant NSF-DMR-1822439 and the Royal Society, Engineering and Physical Sciences Research Council (EPSRC) Grants EP/N010345/1, EP/P026850/1, and EP/S030719/1.

All study data are included in the article and/or supporting information.

1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

22

23

25

26

27

28

29

30

31

32

33

34

35

36

37

38