- Altmetric

All-day passive radiative cooling has recently attracted tremendous interest by reflecting sunlight and radiating heat to the ultracold outer space. While some progress has been made, it still remains big challenge in fabricating highly efficient and low-cost radiative coolers for all-day and all-climates. Herein, we report a hierarchically structured polymethyl methacrylate (PMMA) film with a micropore array combined with random nanopores for highly efficient day- and nighttime passive radiative cooling. This hierarchically porous array PMMA film exhibits sufficiently high solar reflectance (0.95) and superior longwave infrared thermal emittance (0.98) and realizes subambient cooling of ~8.2 °C during the night and ~6.0 °C to ~8.9 °C during midday with an average cooling power of ~85 W/m2 under solar intensity of ~900 W/m2, and promisingly ~5.5 °C even under solar intensity of ~930 W/m2 and relative humidity of ~64% in hot and moist climate. The micropores and nanopores in the polymer film play crucial roles in enhancing the solar reflectance and thermal emittance.

There still remains a big challenge in fabricating highly efficient and low-cost radiative coolers for all-day and all-climates. Here, the authors report a hierarchically structured polymethyl methacrylate film with a micropore array combined with random nanopores for highly efficient day- and nighttime passive radiative cooling.

Introduction

Although the climate-science community is attempting to find efficient solutions for the accelerating global warming and greenhouse gas emissions, few concrete actions have been taken to resolve climate change1–3. Conceptually, one of the most efficient strategies is to reduce the amount of solar irradiance absorbed by the Earth4, e.g., through solar radiation management (SRM), to slow or reverse global warming5–7. The basic idea behind SRM is to seed reflective particles into the Earth’s stratosphere to reduce solar absorption, which might cause potentially dangerous threats to the Earth’s basic climate operations8,9. One possibly alternative approach is passive radiative cooling—a sky-facing surface on the Earth spontaneously cools by radiating heat to the ultracold outer space through the atmosphere’s longwave infrared (LWIR) transparency window (λ ~ 8–13 μm)10–14. However, passive daytime radiative cooling (PDRC) to a temperature below ambient under direct sunlight is a particular challenge because most of the naturally available thermal radiation materials also absorb incident solar irradiance and rapidly heat up under exposure to the Sun15,16. Accordingly, designing and fabricating efficient PDRC with sufficiently high solar reflectance (λ ~ 0.3–2.5 μm) to minimize solar heat gain and simultaneously strong LWIR thermal emittance

The first theoretical design of a metal-dielectric photonic structure for PDRC was presented by Raman et al.25 in 2013 by tailoring the material spectrum responses for continuous daytime radiative cooling. Then, they first experimentally achieved PDRC via a precision-designed nanophotonic radiative cooler in 201426. This cooler, consisting of seven alternating dielectric layers deposited on top of a silver mirror, cooled to 4.9 °C below ambient temperature by reflecting 97% of incident sunlight while strongly and selectively emitting in the atmospheric transparency window. Nonetheless, many photonic structures suffer from a high manufacturing cost and large-scale production limits23,26–28. Another pioneering strategy was recently developed by Yin et al.29, who created a glass-polymer hybrid metamaterial thin film consisting of silica (SiO2) microspheres randomly distributed in the matrix material of polymethylpentene via the scalable-manufactured roll-to-roll polymer extrusion process. With the assistance of a silver coating, the metamaterial was able to exhibit >93% infrared emissivity and reflect ~96% of solar irradiance, achieving a noontime radiative cooling power of 93 W/m2 under direct sunshine. The introduction of polymer-based radiative cooling materials can greatly improve the scalability and applicability of PDRC systems in practical applications18,30–33. Very recently, instead of using a reflective metallic mirror, state-of-the-art PDRC designs, such as porous polymer coatings17,34,35, polymeric aerogels36, white structural wood37 and cooling paints38,39, have attracted considerable attention because of their high cooling performance, simplicity, applicability and economical efficiency. For example, Yu et al.17 made remarkable progress in the design of PDRC poly(vinylidene fluoride-co-hexafluoropropene) coatings with random micro-/nano-pores through a phase inversion-based method, demonstrating high solar reflectance (0.96 ± 0.03), as well as high longwave infrared emittance (0.97 ± 0.02) that enabled cooling up to ~6 °C and ~3 °C below ambient temperature under direct sunlight in dry southwestern USA and south Asia, respectively. Nonetheless, almost all of the PDRC prototypes reported so far performed well in an arid atmosphere (e.g., total precipitable water (TPW) <10 mm) and at relatively low environmental temperatures (e.g., below 25 °C)26,29,36,37, rather than in hot (e.g., 30 °C or above) and humid (e.g., TPW å 20 mm) regions17,30. Theoretically, atmosphere humidity or TPW heavily influences the absorbed power density of atmospheric radiation and the magnitude of the cooling performance. In a dry environment, the atmospheric window is open not only in the 1st atmospheric transparency window (8–13 µm) but also in the 2nd atmospheric transparency window (16–25 µm), making efficient thermal radiation possible23,30. However, in a hot and humid environment, the transmissivity of the atmosphere slightly decreases in the 1st atmospheric transparency window and dramatically drops in the 2nd atmospheric transparency window. Thus, the cooling performance naturally becomes lower and is even limited due to the increased downwelling atmospheric radiation induced by higher humidity and temperature40–42. Therefore, developing facile, scalable, and cost-effective PDRC for practical thermal radiation applications, including hot and humid regions, still remains a great challenge.

Inspired by these intelligent reports and above considerations, herein, we design and report a hierarchically porous array PMMA (PMMAHPA) film with a close-packed micropore array on the surface combined with abundant random nanopores inside by a template method. The as-obtained PMMAHPA film demonstrates excellent

Results and discussion

ρ ¯ solar ε ¯ LWIR

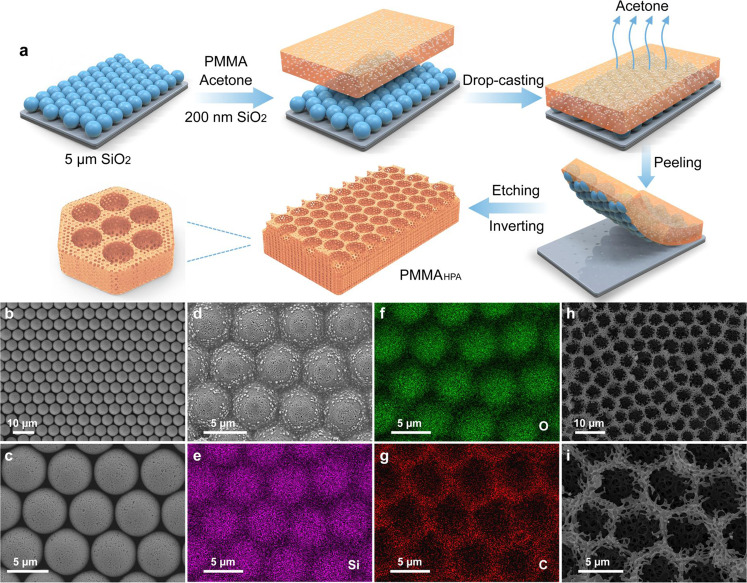

Fig. 1a illustrates the fabrication process of PMMAHPA. In brief, a monolayer of a hexagonally close-packed 5 μm SiO2 array is fabricated using a facile unidirectional rubbing assembly method43,44, as shown in Fig. 1b, c. A dispersion of PMMA and 200 nm SiO2 nanospheres in acetone is then infiltrated into the SiO2 monolayer template. After the rapid evaporation of acetone in air, the obtained PMMA/SiO2 composite displays randomly distributed SiO2 nanospheres and regularly distributed SiO2 microspheres, as indicated by the micrograph and EDS elemental mappings (Fig. 1d–g). After removal of the SiO2 nanospheres and the monolayer template by etching in hydrofluoric acid aqueous solution, a hierarchically porous array PMMA (PMMAHPA) film with ordered symmetrical micropores (~4.6 μm diameter) and randomized nanopores (~250 nm average diameter) can be obtained (Fig. 1h, i and Supplementary Figs. 1a–c). Fourier transform infrared (FTIR) spectra and thermogravimetric analysis (TGA) confirm that PMMAHPA is entirely composed of organic polymer without residual inorganic SiO2 (Supplementary Figs. 1d and e), while the 49.4 wt% of SiO2 before etching indicates a high porosity of PMMAHPA (Supplementary Fig. 1f).

Fabrication and characterization of the PMMAHPA film.

a Schematic illustration of the fabrication of PMMAHPA with a hierarchically porous array. b, c SEM micrographs of hexagonally close-packed monolayer SiO2 templates. d SEM micrograph of PMMA/SiO2 composite. e–g EDS elemental mappings of Si, O, and C in d, showing the randomly distributed SiO2 nanospheres and regularly distributed SiO2 microspheres of the composite. h, i SEM micrographs of PMMAHPA showing an ordered symmetrical micropores array made of hierarchical randomized nanopores.

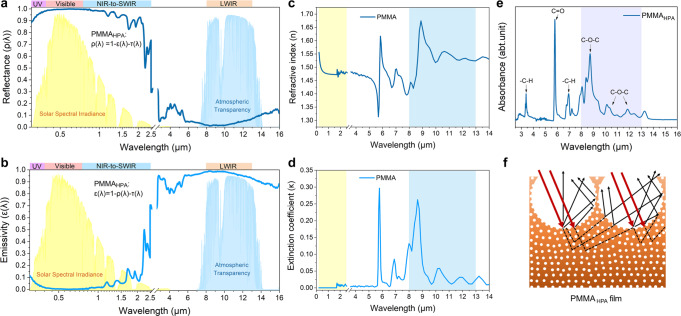

Figure 2 demonstrates the spectral reflectance and emissivity of the PMMAHPA film with ~160 μm effective thickness according to the normalized ASTM G173 Global solar spectrum and the LWIR atmospheric transparency window. The PMMAHPA film with ~60% porosity presents a high average solar reflectance (

Spectroscopic response of the PMMAHPA film.

a, b Spectral reflectance and emissivity of the PMMAHPA film with ~160 μm effective thickness along with the normalized ASTM G173 Global solar spectrum and the LWIR atmospheric transparency window. c, d Spectral refractive index (n) and extinction coefficient (κ) of PMMA, showing negligible absorptivity in the solar range and multiple extinction peaks in the LWIR wavelengths. e Absorbance spectrum of PMMAHPA measured with ATR-FTIR spectroscopy. f Schematic diagram showing the periodic re-entrant structure with nano/microscale pores is conducive to enhance the total scattering efficiency by multiple reflections.

As one of the most widely used and low-cost polymers, pristine PMMA film has ideal intrinsic properties to enable high-performance PDRC applications47. Figure 2c, d show that PMMA has negligible extinction coefficient in the solar wavelengths and multiple extinction peaks at the 8, 8.6, 10.3, 11.8, and 13.2 μm within the LWIR window, which should result from the different vibrational modes of its molecular structure. These properties keep the heat gain from sunlight to a minimum and contribute to a large amount of infrared absorption/emission in the atmospheric transparency window, which is responsible for the superior PDRC. Furthermore, the absorbance spectrum measured with attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR) exhibits strong infrared absorption due to C–O–C stretching vibrations between 770 and 1250 cm−1 (8–13 μm, Fig. 2e), which coincidently lie in the atmospheric transparency window. Importantly, the periodic re-entrant structure with hierarchical nano/microscale pores is conducive to enhance the total scattering efficiency and increase the probability of infrared absorption/emission through multiple diffuse reflection at various incident angles (Fig. 2f). All these features benefit the radiative heat exchange between the cooling structural polymer and the atmosphere, causing sufficiently high

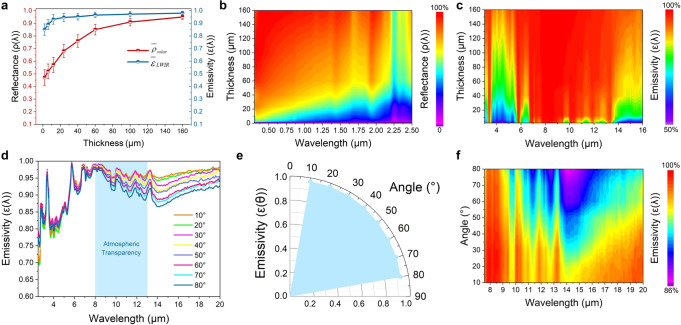

Different from transparent pristine PMMA, the PMMA/SiO2 composite film is translucent due to the absorptance in the UV and visible regions, and the corresponding PMMAHPA film has negligible transmittance because its plenty of pores can efficiently scatter sunlight of all wavelengths (Supplementary Figs. 3a–d). The spectral transmittance of the PMMAHPA film decreases with increasing thickness (Supplementary Fig. 4). Accordingly, the solar reflectance appears to have a more pronounced increasing trend with thickness than the thermal emittance in the range of 8–13 μm (Fig. 3a–c), which likely arises from the increased backscattering of light from the thicker, nonabsorptive, porous PMMA layer. Evidently, even the emittance of the only effectively ~2 μm thick PMMAHPA film can reach 0.85. This suggests that the porous structure is sufficient to augment the intrinsic emittance of PMMAHPA. Further, we experimentally and theoretically demonstrated the influence of pore sizes and porosity on the optical performance. As clearly seen in Supplementary Fig. 5a, the PMMAHPA with ~500 nm nanopores shows a high-level

Variation in

a Variation in

Figure 3d–f demonstrate the emissivity spectra of the PMMAHPA film in the infrared range of 2.5–20 µm at different polarization angles.

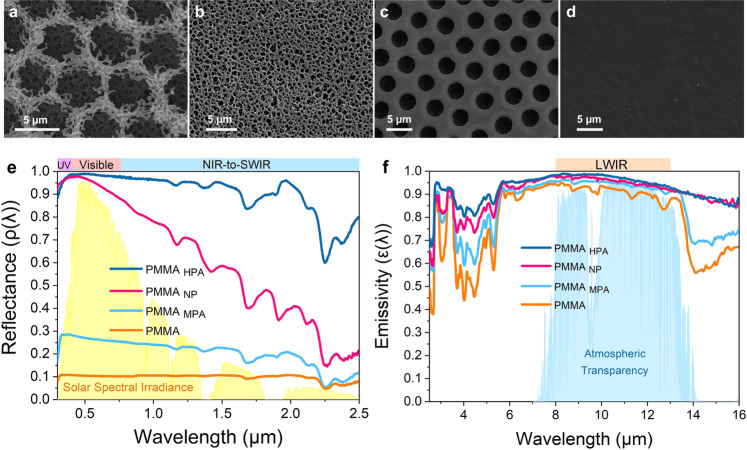

To investigate the influence of the hierarchical porous structure on the optical properties of the PMMAHPA film, we further compared it with three other types of PMMA films, nanopore PMMANP, monolayer micropore array PMMAMPA and pristine PMMA, as shown by the SEM images in Fig. 4a–d. Figure 4e shows that the PMMAHPA film presents the highest average solar reflectance (

SEM micrographs and optical properties of different types of PMMA films.

a–d SEM micrographs of the PMMAHPA, PMMANP, PMMAMPA, and pristine PMMA films. e Reflectance spectra across the solar wavelengths of different types of PMMA films. f Infrared emissivity spectra of different types of PMMA films.

The experimental results of four types of PMMA films were also theoretically verified by FDTD simulations (Supplementary Fig. 7)49. The numerical simulation results further reveal that hierarchical porous structure containing dual-scale nano/micro cavities would significantly improve the broadband scattering performance contrast to uniform nanoscale porous structure, especially in the range of NIR-to-SWIR, while the LWIR thermal emissivity of the two kinds of structures has negligible changes. The theoretical model of PMMAMPA verifies that the ordered micropores monolayer does not have enough high scattering coefficient, which matches well with the experimental result. We also simulated the reflectance spectra across the solar wavelengths of the PMMAHPA film with thickness of ~5 µm (effectively ~2 µm, Supplementary Fig. 8). Surprisingly, such thin film is sufficient to yield an efficient scattering (

Besides, to verify the optical superiority of the periodic micropores array on the surface, we also investigated the optical properties of a hierarchically porous PMMA (PMMAHP) film with loose-packed random micropores and nanopores (Supplementary Figs. 9a–c). The solar reflectance of the PMMAHP film drops 8% in the range of NIR-to-SWIR compared to PMMAHPA (Supplementary Fig. 9d), which contains about 5% of sunlight (

Furthermore, the PMMAHPA film was modified by fluorosilane to become superhydrophobic with a water contact angle (WCA) of ~156° (Supplementary Fig. 10) for stable durability in various atmospheric humidity conditions. Both the solar reflectance and infrared emissivity are at high levels and vary negligibly after fluorosilane treatment (Supplementary Figs. 11a and b). Even after accelerated weathering treatment for 480 h (each cycle including the UV irradiation at 310 nm wavelength with intensity of 0.71 W/m2 at 60 °C for 4 h, followed by condensation at 50 °C for 4 h with UV lamps off), the PMMAHPA films exhibit no blistering, peeling, cracking and color changing. The porous morphology of our PMMAHPA films basically remains the same (Supplementary Figs. 12a and b). The ATR-FTIR spectra further demonstrate that the surface-modified PMMAHPA films before and after weathering treatment all have obvious absorption peaks of C=O at 1726 cm−1, C–F at 1187 cm−1, C–O–C at 1139 cm−1 and C–Cl at 779, 746, 700, and 651 cm−1 (Supplementary Fig. 12c), owing to the protection of fluorosilane molecules. Moreover, the constant WCAs in Supplementary Fig 12d after weathering treatment also indicate the excellent durability and potential applicability. The reflectance and emissivity spectra of the PMMAHPA films show slight fluctuations of solar reflectance (

All-day continuous passive radiative cooling measurements of the PMMAHPA film

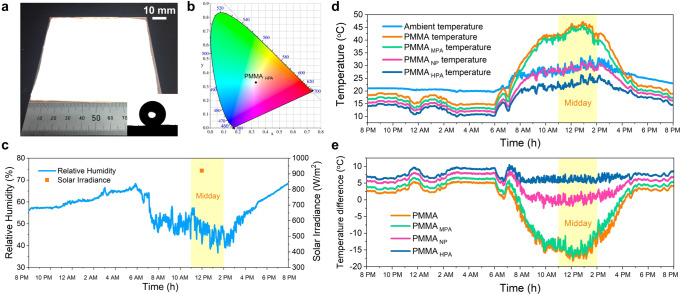

The radiative cooling performances of the structural polymers (~160 μm effective thickness and 100 mm × 100 mm in size) were measured from 20:00 on 09 Oct. to 20:00 on 10 Oct. 2019 using a 24-h uninterrupted thermal measurement on a flat roof of a five-story building under a clear sky in Shanghai, China. As shown in Fig. 5a, the strong optical scattering of sunlight gives our PMMAHPA surface a matte and white appearance, which can be further confirmed by the CIE chromaticity coordinate analysis (Fig. 5b). Under intense solar irradiance of ~930 W/m2 and relative humidity of ~40% at noon (Fig. 5c), the real-time temperature tracking of the air and four types of PMMA films are shown in Fig. 5d. Evidently, although the pristine PMMA and PMMAMPA films can exhibit decreases in temperature by ~3.7 °C and ~4.9 °C at night, respectively, their temperatures dramatically rise to ~15.2 °C and ~14.1 °C above the ambient temperature at noon due to their transparency and translucency, respectively (Fig. 5e). The PMMANP film can achieve a subambient cooling of ~6.5 °C during the night but maintains almost the same temperature as the ambient environment during midday. In contrast, the PMMAHPA film exhibits fabulous passive radiative cooling during both night and daytime. The average below-ambient temperature of the PMMAHPA film is ~8.2 °C during the night (between 6 p.m. and 6 a.m.) and ~6.0 °C during midday (between 11 a.m. and 2 p.m.). This cooling performance is on par with those in previous reports (Supplementary Table S2).

Twenty-four-hour continuous passive radiative cooling performance measurements.

a Photograph of the cooling PMMAHPA film showing its bright white appearance (inset, water contact angle image of PMMAHPA). b CIE chromaticity coordinates of the cooling PMMAHPA film. c Relative humidity tracking of the air and solar irradiance at 12 PM on 10 Oct. 2019. d Temperature tracking of the air and PMMA films. e Temperature difference between the ambient and structural PMMA films.

Subambient PDRC performance in various geographical regions and climates

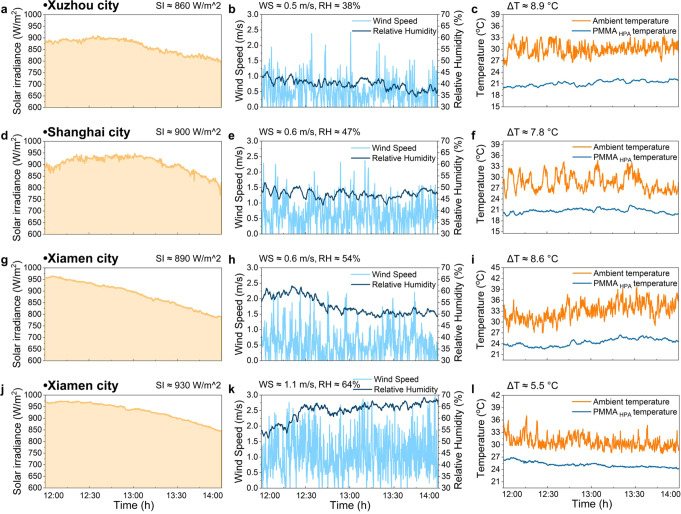

Radiative cooling performance in real-world applications is substantially affected by the geographical regions and climates. For instance, the net radiative cooling power of the cooler is limited by the increased solar irradiation, humidity, cloud cover, local wind speed and ambient temperature30,50. Here, we further performed a series of experiments to evaluate and compare the effects of climates from different cities on the radiative cooling performance of our PMMAHPA films. Three cities, Xiamen city (Southern China, Coastal), Shanghai city (Eastern China, Coastal) and Xuzhou city (Northern China, Inland), were chosen as typical test locations due to their different topographic and meteorological characteristics (Supplementary Fig. 13). The climate characteristics in Xuzhou, Shanghai and Xiamen are temperate monsoon climate, subtropical monsoon climate and subtropical marine monsoon climate, respectively, which provide a remarkable difference in humidity for our measurements. As shown in Fig. 6a–i, under clear skies with comparable solar intensity and wind speed but various humidity conditions (~38% in Xuzhou, ~47% in Shanghai, and ~54% in Xiamen), the subambient cooling of ~8.9 °C, ~7.8 °C and ~8.6 °C at noontime is observed, separately. Even in the same location (e.g., in Xiamen city), increasing solar intensity (from ~890 W/m2 to ~930 W/m2), wind speed (from ~0.6 m/s to ~1.1 m/s) and humidity (from ~54% to ~64%), the PMMAHPA film still enables cooling up to ~5.5 °C below ambient temperature (Figs. 6g–l), which has not been reported previously40,41. Comparing Xuzhou and Xiamen city (Fig. 6a–c and j–l), we can conclude that increasing solar intensity (from ~860 W/m2 to ~930 W/m2), wind speed (from ~0.5 m/s to ~1.1 m/s) and humidity (from ~38% to ~64%), the subambient cooling temperatures of PMMAHPA film are indeed influenced (decreasing from ~8.9 °C to ~5.5 °C). The primary driver of the good performance in various geographical regions and climates should be the synergistic result of visible white (high solar reflectance) and infrared black (high infrared emissivity in both the 1st and 2nd atmospheric transparency window) that greatly minimizes the absorbing solar irradiance and the thermal radiation emitted by the atmosphere. In addition, we investigated the effect of surface modification on the daytime radiative cooling performance of the PMMAHPA film. The results show that the PMMAHPA films with and without surface modification can achieve subambient cooling temperatures of ~6.9 °C and ~6.5 °C, respectively (Supplementary Fig. 14). While the PMMAHPA film without surface modification also demonstrates excellent passive radiative cooling behavior, the fluorosilane treatment enables stable performance by restricting the effect of moisture and water under different levels of humidity.

Passive daytime radiative cooling performance of the PMMAHPA film in different locations and weathers.

a–c Solar irradiance, wind speed and relative humidity, and temperatures of the air and the PMMAHPA film in Xuzhou city. d–f Solar irradiance, wind speed and relative humidity, and temperatures of the air and the PMMAHPA film in Shanghai city. g–i Solar irradiance, wind speed and relative humidity, and temperatures of the air and the PMMAHPA film in Xiamen city. j–l Solar irradiance, wind speed and relative humidity, and temperatures of the air and the PMMAHPA film in Xiamen city.

Passive radiative cooling power measurements of the PMMAHPA film

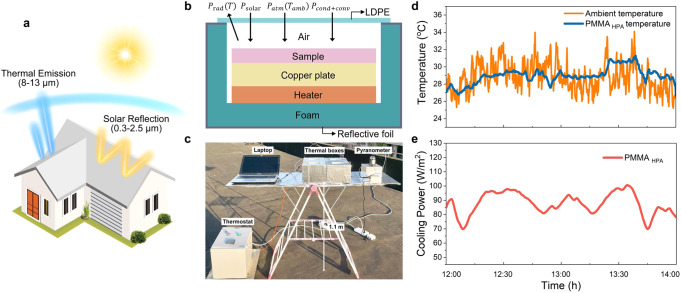

When used in a building roof or external siding, our PMMAHPA films can achieve all-day passive radiative cooling through reflecting sunlight and radiating heat to the cold outer space under a clear sky (Fig. 7a). Figure 7b schematically shows the direct thermal measurement system based on the net cooling equation. To further demonstrate the PDRC capability of the cooling PMMAHPA, we adopted a feedback-controlled heating system to measure its radiative cooling power during the midday (Fig. 7c). This feedback-controlled heating system maintains the surface temperature of the PMMAHPA film at the measured ambient temperature to minimize the impact of conductive and convective heat losses (Fig. 7d). Promisingly, the PMMAHPA film attains an average cooling power of ~85 W/m2 under solar intensity of ~900 W/m2 in April in Shanghai (Fig. 7e).

Net cooling power of the PMMAHPA film during the midday.

a Schematic of the basic principles of PDRC. When used in a building roof or external siding, the PMMAHPA film exhibits high solar reflectance and high infrared emissivity. b Two-dimensional schematic drawing of the thermal box apparatus with a feedback-controlled heater. The heater maintains the sample surface temperature at that of the ambient environment, minimizing convective and conductive heat losses. c Photo of the experimental apparatus on a rooftop in Shanghai, China. d Temperature tracking of the ambient and the PMMAHPA film under solar intensity of ~ 900 W/m2 and relative humidity of ~ 44% on April 23, 2020. e Continuous measurement of the radiative cooling power of the PMMAHPA film during the midday.

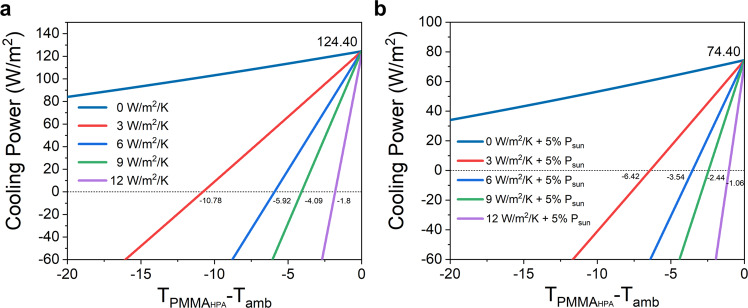

Figure 8a, b present the net cooling power during the nighttime and daytime calculated using the radiative cooling theoretical model, respectively. More details of this model are given in the “Methods” section. The power of solar radiation is set to approximately 1000 W/m2 for simplicity, and the ambient temperature Tamb is assumed to be 298.15 K in both cases. A maximum cooling power of 124.40 W/m2 can be achieved for nighttime operation. For daytime operation, the calculated maximum net cooling power is 74.40 W/m2 at thermal equilibrium, which is lower than the measured daytime cooling power due to the fluctuations in the ambient conditions, the uncertainty in the measurements and the theoretical model approximations.

Calculated net cooling power with software MATLAB based on the theoretical simulation.

a Calculated net cooling power during the nighttime. b Calculated net cooling power during the daytime. The variable hc is a combined nonradiative heat coefficient. Values of 0, 3, 6, 9, and 12 for hc are used in the calculations. For daytime calculations, 5% solar power absorption is considered.

In summary, we have demonstrated and fabricated a hierarchically structured PMMA film with a dense micropore monolayer array and randomly distributed nanopores for highly efficient all-day passive subambient radiative cooling in various geographical locations and climates. Our structural polymer film exhibits sufficiently high solar reflectance and thermal emittance owing to its abundant periodic scattering micropores embedded with random nanopores and ideal intrinsic properties. Without needing any silver or aluminum reflectors, our cooling structural PMMA film realizes an average below-ambient temperature ~8.2 °C during the night and ~6.0 °C to ~8.9 °C during midday, and promisingly ~5.5 °C even under solar intensity of ~930 W/m2 and relative humidity of ~64% in hot and moist subtropical marine monsoon climate, which is really an all-day and all-climate PDRC system. And the superhydrophobized PMMAHPA film can ensure cooling performance durability by eliminating the effect of moisture and water under different levels of humidity. This study has revealed the effects of micropores, nanopores and their arrangement on optical performance, which may provide deep insight into the crucial roles of various pores and their array in solar reflectance and thermal emittance and help us design and fabricate more efficient all-day passive subambient radiative cooling materials and systems.

Methods

Fabrication of PMMAHPA

Monodisperse 5 μm SiO2 microspheres were placed on top of a polydimethylsiloxane (PDMS)-coated glass sheet and rubbed with another PDMS substrate with slight palm pressure along a randomly chosen direction according to our reported method43,44. After being rubbed for 5 s, the SiO2 microspheres had assembled into hexagonally close-packed monolayers on the PDMS surfaces. A 200 nm SiO2 nanosphere dispersion in acetone was added to PMMA to make a dispersion of SiO2-acetone-PMMA (1:10:1 mass ratio) under magnetic stirring at 50 °C for 2 h. This dispersion was then drop-cast onto the monolayer SiO2 template. After the solvent was fully evaporated, a freestanding PMMA/SiO2 composite film was obtained by peeling the coating off the smooth surface. After removal of the SiO2 template and nanospheres with 2-5 vol% hydrofluoric acid aqueous solution, PMMAHPA films with various effective thicknesses of 2 ± 0.5 µm to 160 ± 5 µm were obtained by casting different amounts of solution. For comparison, PMMANP film was fabricated by the same procedure above without using the monolayer SiO2 template, PMMAMPA film was obtained without SiO2 nanospheres, and the pristine non-porous PMMA film was prepared at an acetone-PMMA (10:1 mass ratio) without using SiO2 particles. In addition, PMMAHP film was fabricated using random loose-packed monolayer 5 μm SiO2 templates and 200 nm SiO2 nanosphere. All the films above have the same effective thickness by controlling the PMMA mass and film-forming substrate size.

PMMAHPA surface modification

To make superhydrophobic PMMAHPA film, the sample was treated with 1H,1H,2H,2H-perfluorooctyltrichlorosilane (PFOTS) via a chemical vapor deposition (CVD) method. In detail, the PMMAHPA film and a vial containing 1% PFOTS/ethanol solution were placed in a sealed vacuum desiccator. The desiccator was immediately pumped to vacuum for 15 min and placed at room temperature for 24 h for fluorination. The modified PMMAHPA film was then baked in an oven at 80 °C for 1 h to remove the excessive PFOTS.

Characterization

Optical characterization of the cooling structural polymers

The spectral reflectance (ρ (λ)) and transmittance (τ (λ)) in the ultraviolet, visible and near-infrared (0.3–2.5 μm) wavelength ranges were separately determined in an UV-Vis-NIR spectrophotometer (Hitachi, U-4100, Japan) with a polytetrafluoroethylene integrating sphere. The ρ (λ) and τ (λ) in the mid-infrared wavelength ranges were characterized in an FTIR spectrometer (Nicolet 6700, Thermo Fisher Scientific, USA) equipped with a gold integrating sphere. We put one black substrate behind the samples during spectral reflectance measurement to eliminate the reflectance contribution of the substrate. The average value of more than five parallel measurements on different sites of the film was reported and the error bars represent the standard deviation. A polarizer was used in the FTIR spectrometer equipped with a smart diffuse reflectance accessory to measure the reflectance over a range of polarization angles (θ) from 10° to 80°. For any object at thermal equilibrium, the spectral absorptivity (α (λ)) and emissivity (ε (λ)) must be equal according to Kirchhoff’s law; thus, ε (λ) was calculated as ε (λ) = 1–ρ (λ)–τ (λ)51,52. The angular reflectance spectra in the wavelength range of 0.4–1.1 μm at different incidence angles were measured by an angle-resolved photonic spectral system (R1, Ideaoptics Technology Ltd., China). Refractive index and extinction coefficient measurements in the wavelength range of 0.2–14 μm at 60° were taken for pristine PMMA films using a V-VASE and an IR-VASE ellipsometer (J. A. Woollam, USA).

Theoretical model of the radiative cooling performance

When the structural polymer films are exposed to a clear sky, they are influenced by the solar irradiance and atmospheric downward thermal radiation. Meanwhile, heat can be transferred from the ambient surroundings to the polymers via conduction and convection due to the temperature difference between the cooling polymers and the ambient environment. To achieve PDRC, the device must satisfy very stringent constraints as dictated by the power balance equation. The net cooling power Pcool of the structural polymers is expressed as26:

The average solar reflectance (

Thermal measurements of cooling temperature and cooling power with a feedback-controlled heater

We designed a feedback-controlled program to minimize both conductive and convective heat exchange to the structural polymers under strong solar irradiance based on Eq. (1)29. Our thermal box consisted of insulation foam covered by a layer of reflective foil. A 10-µm-thick transparent low-density polyethylene film was used to seal the thermal box and served as a wind shield. Moreover, a PMMAHPA film with a size of 100 mm × 100 mm × 160 µm was placed on a 100 mm × 100 mm × 1 mm thick copper plate attached to a 100 mm × 100 mm × 0.2 mm thick Kapton heater. The Kapton heater was feedback-controlled by an ambient temperature-responsive thermostat to maintain the PMMAHPA film at ambient temperature and accurately assess the cooling power. The apparatus was elevated 1.1 meters above the ground to avoid heat conduction from the ground to the thermal box. An adhesive resistant temperature detector was directly mounted on the back surface of the polymer film to detect real-time temperature of the sample, which was continuously recorded by a datalogging thermometer with an uncertainty of ± 0.1 °C (CENTER309, CENTER corp, Taiwan, China). For comparison, a temperature detector was mounted outside the box to detect real-time temperature of the ambient. A relative humidity (RH) data logger with an accuracy of ± 0.1% RH (GSP-8, Elitech corp, China) was placed near the samples to measure the relative air humidity. The solar irradiation outside the box was simultaneously recorded using a datalogging solar radiometer with an accuracy of ± 5% (TES1333R, TES Electrical Electronic corp. Taiwan, China). It is worth mentioning that the sunlight our PMMA films received is ~10% less than the pyranometer measured due to the polyethylene cover on the thermal box. The wind speed around our thermal boxes was measured using a digital anemometer with an accuracy of ±2.5% (AS856, Smart Sensor corp, China). All weather data were automatically tracked every 10 s. The heater was switched on to test the radiative cooling power, but the heater and copper plate were removed to demonstrate the subambient cooling performance. As a control, we exposed the PMMANP, PMMAMPA and pristine PMMA films to the sky while mounted in the same apparatus to compare the subambient cooling performances. Demonstrations of the cooling performance of different types of PMMA films during both day and night were carried out under a clear sky with a relative humidity of ~ 40% at noon in on a flat roof of a five-story building at Fudan University, Shanghai, China on October 09, 2019. The daytime cooling performance of the PMMAHPA film in different locations and climates was conducted in April and May, 2020, such as Xiamen city (Southern China, Coastal, 24° 26’ 57” N, 118° 3’ 35” E), Shanghai city (Eastern China, Coastal, 31° 18’ 22” N, 121° 30’ 17” E) and Xuzhou city (Northern China, Inland, 34° 27’ 55” N, 117° 0’ 51” E).

Supplementary information

Supplementary information is available for this paper at 10.1038/s41467-020-20646-7.

Acknowledgements

We appreciate the financial support provided for this research by the National Key Research and Development Program of China (2017YFA0204600 and 2020YFE0100300) and the National Natural Science Foundation of China (52033003 and 51721002).

Author contributions

L.W., T.W., and M.C. conceived the concept and designed the research. T.W. and Y.W. conducted the experiments. T.W. and L.S. conducted the FDTD simulations. T.W. created the schematics. L.W. and T.W. wrote the manuscript. All authors including X.H. discussed the results and commented on the manuscript.

Data availability

All data needed to evaluate the conclusions in the paper are presented in the paper and/or the Supplementary information. Additional data related to this paper may be requested from the authors.

Competing interests

The authors declare no competing interests.

References

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

A structural polymer for highly efficient all-day passive radiative cooling

A structural polymer for highly efficient all-day passive radiative cooling