Competing Interests: The author has declared that no competing interests exist.

- Altmetric

- Introduction

- Economic centralization, technical innovation and production serialization at Late Chalcolithic Arslantepe

- Wares, forming techniques and morphometric analyses

- Geological setting and raw material supply

- Sampling strategy and methods

- Results

- Discussion and conclusions

- Supporting information

This paper proposes a new range of diversity indexes applicable to ceramic petrographic and geochemical data and potentially to any archaeological data of both metric and non-metric nature in order to assess the degree of craft standardization. The case study is the Late Chalcolithic pottery from Arslantepe in eastern Anatolia, ideal to test the standardization hypothesis, i.e. the assumed correspondence between craft standardization and increased rates of production, which in turn correlate with economic specialization. The results suggest that the procurement and processing of raw materials are more sensible indicators of standardization than vessel shape variability. Higher standardization is connected with the scale of production rather than with the use of the wheel or its rotational speed. The socio-economic centralization marks a process of labor division within the operational sequence and, more generally, a shift from communal to more segregated potting practices. As a result, the variability of both technical procedures and end products increases. In contrast univocal trends towards standardization can be found in coeval contexts from northern Mesopotamia, where the incipient urbanization served to create bonds between vessel makers, favoring the transmission of models and practices regardless of the centralized power.

Introduction

Standardization is commonly perceived as a process of reduction in artifact variability at several levels: raw materials composition, manufacturing techniques, forms and dimensions as well as decorations. The standardization of products is generally assumed to be the result of a higher rate of production that typically characterizes the economic organization of early complex societies [1–10]. The surplus centralized by the elites allowed some individuals to be exempted from the primary production and focus more intensively on craft activities in exchange for food. This enhanced the routinization and mechanization of gestures that was reflected in an increased homogenization of finished products [3, 11, 12]. Therefore, the increased standardization has been often viewed as indicating the activity of specialized artisans. However, the relationship between artifact standardization and craft specialization is far from linear and has been called into question by several ethnoarchaeological studies [3, 10, 13–18]. In pottery production, increased levels of standardization and specialization are commonly associated with the introduction of rotating devices in the manufacturing process. On the one hand, this technological innovation required the acquisition of specific motor skills through long apprenticeship and continuous practice and, on the other hand, it favored the repetitiveness of gestures and enhanced production times and rates [19–21].

So far, standardization studies on archaeological ceramics have mainly focused on measuring the vessels’ dimensional variation through a sophisticated range of measures [5, 18, 22–28], while non-metric attributes, such as typological and technological attributes, have received less attention [however, see 29–34]. In the last two decades the assessment of compositional variability has gained importance, but the integration between petrographic and geochemical data as well as the correlation with morphological, dimensional and technological variables need to be further explored [31, 33–39].

This paper intends to exploit the potential of compositional analyses for assessing craft specialization and artifacts’ standardization. The case study is the Late Chalcolithic (ca. 4700–3200 BCE cal.) pottery assemblage from Arslantepe in eastern Anatolia, ideal to test the standardization hypothesis. The standardization hypothesis proposes that more uniformity in the vessel assemblages is due to higher rates of production, which create task mechanization and routinization (i.e. motor habits) [3–6, 11, 27]. Many scholars consider craft standardization as evidence of specialization, thus as a key aspect in the political economy of complex societies [2, 36, 40]. As argued by Hilditch [33], craft standardization has been frequently seen as the result of a unilinear process intensified by the introduction of the potter’s wheel that enhanced both time and scale of production; however, little attention has been dedicated to single variations along the chaîne opératoire to assess where and how standardized gestures and behaviors appear.

In his paper “Does the standardization of ceramic pastes really mean specialization?” Arnold claimed that paste composition provides information primarily on the geological context rather than on the production organization [41]. His assumption was based on geochemical data of ceramic vessels produced at a household level from different ethnographic communities in Mexico, Peru and Guatemala. The present paper demonstrates instead that the variations in paste recipes can be used as indicators of production organization at least at an intra-site level. To achieve this aim, different compositional analyses—i.e. bulk geochemistry and thin section petrography—have to be integrated with selected technological and typological features. Interpretations in terms of production organization are further favored in cases of variegated pottery assemblages related to distinct levels of specialization and produced over a long time span marked by drastic socio-economic changes.

The aim of this paper is to assess whether the gradual process of economic centralization that led to the formation of an early state society by the end of the 4th millennium BCE at the site of Arslantepe (Malatya, Turkey) implied the homogenization and increased standardization of pottery production and, in particular, of the raw material procurement patterns and paste preparation modes. To this end, petrographic and geochemical data of locally-produced vessels are elaborated using procedures borrowed from diversity statistics. Finally, the trends identified are compared with vessel shape variability, manufacturing techniques and production rates, in order to detect differences and correlations in technological variations within the various steps of the chaîne opératoire.

Economic centralization, technical innovation and production serialization at Late Chalcolithic Arslantepe

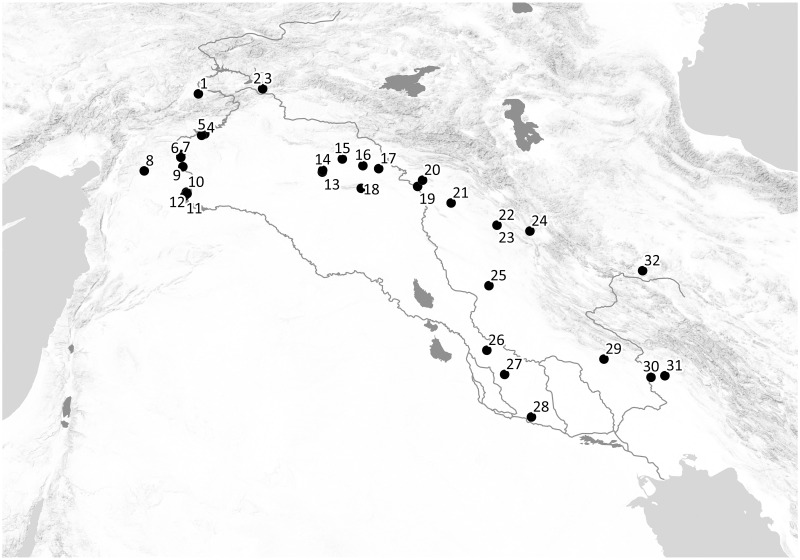

Arslantepe is a multi-layered settlement located in the Malatya Plain in Eastern Anatolia, a few kilometers south of the Euphrates River and on the northern side of the Anti-Taurus Mountains (Fig 1). The Late Chalcolithic phases reveal the site’s historical relevance in the formation process of early-state societies and the emergence of social and economic inequality [42–45]. During the Late Chalcolithic period all Mesopotamia and related regions—including the upper courses of the Euphrates and Tigris in Anatolia, the Trans-Tigridian regions, and the Amuq and Susiana plains—share structural changes in the economic and political organization of the communities. These results in the emergence of complex societies characterized by political hierarchies, economic centralization and, in many areas, the first urban centers [45, 46].

Location of the main investigated Late Chalcolithic sites in greater Mesopotamia.

1. Arslantepe; 2. Tepecik; 3. Norşuntepe; 4. Samsat; 5. Kurban Höyük; 6. Hacınebi Tepe; 7. Zeytinli Bahçe Höyük; 8. Oylum Höyük; 9. Jerablus Tahtani; 10. Jebel Aruda; 11. Habuba Kabira South; 12. Tell Sheikh Hassan; 13. Tell Brak; 14. Tell Feres al-Sharqi; 15. Tell Leilan; 16. Tell Hamoukar; 17. Tell el-Hawa; 18. Grai Resh; 19. Nineveh; 20. Tepe Gawra; 21. Surezha; 22. Logardan; 23. Girdi Qala; 24. Gerdi Resh; 25. Tell Rubeidheh and Tell Hassan; 26. Tell Uqair; 27. Abu Salabikh; 28. Uruk; 29. Teppe Farukhabad; 30. Susa; 31. Chogha Mish; 32. Godin Tepe. Map: M. Karaucak through the topographic data courtesy of Shuttle Radar Topography Mission (SRTM), DOI:/10.5066/F7K072R7.

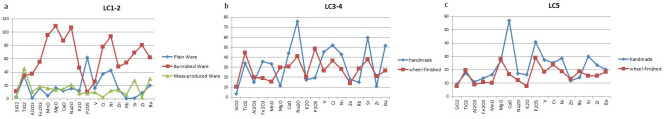

The rich Late Chalcolithic pottery assemblages of Arslantepe, all found in primary contexts, refer to various spheres of pottery production and manufacturing traditions, and provide a significant record to investigate organizational, economic, and cultural changes. The Late Chalcolithic sequence is divided into three main phases corresponding to the Late Chalcolithic 1–2, Late Chalcolithic 3–4 and Late Chalcolithic 5 in the Mesopotamian chronology [46, 47]. The first Late Chalcolithic phase (LC1-2 or Arslantepe period VIII in the site sequence: ca. 4700–3900 BCE) consists in eight levels excavated so far; all are characterized by small domestic units, typically with some rooms devoted to food processing [48, 49]. The pottery is entirely handmade throughout the whole period, with surfaces either scraped or left plain, while burnishing and slipping rarely occur among surface treatments (Fig 2a and 2b). As for shapes, bowls predominate over beakers, basins, bottles, jars, and pithoi. Approximately 15% of the pottery is mass-produced (Fig 2b), namely light-colored coarse chaff-tempered bowls with scraped bottoms generally referred to as “Coba bowls” [50]. In the pottery assemblages of all Mesopotamia this period marks the disappearance of painted decorations and high-fired fine grit fabrics, testifying to a new role of ceramic containers within the communities [30, 48]. Pottery production loses its symbolic and representative character and becomes oriented towards efficiency, functional goals and serialization. These changes are related to increasingly repetitive and more and more widely shared social practices such as food consumption and redistribution.

Examples of LC pottery from Arslantepe.

a. LC1-2 storage jars and kitchen wares; b. LC1-2 handmade Coba Bowl; c. LC3-4 wheel-finished cooking pot; LC3-4 handmade cooking pot; e. LC3-4 wheel-finished mass-produced bowls; f. LC3-4 wheel-finished red-slipped ware (RIB) small jar; g. LC5 wheel-made light-colored fine ware jarlet; h. LC5 wheel-made light-colored coarse ware mass-produced bowls; i. LC5 handmade red-black burnished ware high-stemmed bowl; j. LC5 handmade kitchen ware and storage jar. Image: Archive of the Missione Archeologica Italiana in Anatolia Orientale (MAIAO).

Increasing social complexity at Arslantepe is more clearly visible in the subsequent Late Chalcolithic phases. During the Late LC3-4 (period VII: ca. 3900–3400 BCE), the settlement enlarges and becomes internally structured in residential and public areas [44]. Two large tripartite buildings occupied the uppermost part of the hill; their monumentality and decorations together with the thousands of clay sealings and mass-produced bowls (Fig 2e) found in them have been interpreted as evidence of ritualized redistributive activities [45: 8–10, 51]. This phase marks also the introduction of rotating devices in the ceramic manufacturing process. In addition to the wheel-finished mass-produced bowls, the pottery assemblage comprises wheel-finished plain or red-slipped burnished jarlets, beakers and jars as well as handmade and wheel-finished globular cooking pots [52, 53] (Fig 2c, 2d and 2f). The occurrence of marks on some wheel-finished vessels has been interpreted as a means for the producers to recognize their own pots in shared drying areas and firing facilities [54, 55]. At the end of the period, a few handmade red-black or monochrome burnished vessels—mainly high-stemmed bowls—of Central-Anatolian influence appeared [56], and this coincides with the first attestation at the site of a caprine-oriented husbandry strategy [57].

During the final phase of the Late Chalcolithic (LC5, Arslantepe period VIA: ca. 3400–3200 BCE) the centralization of resources progressed and a local ‘early state’ society with a proto-palatial complex was established at the site [42, 44, 58–62]. The mass-production of bowls (Fig 2h) devoted to the redistribution of meals increased due also to the hypothesized introduction of the fast wheel in the manufacturing process, and potter’s marks totally disappeared. The rest of the ceramic repertoire (Fig 2g and 2j) comprises wheel-finished light-colored jars, jarlets and high-stemmed bowls, as well as handmade storage containers and cooking pots [62–65]. The handmade red-black and monochrome burnished vessels (Fig 2i) increase in number and now exhibit a wider formal and functional repertoire including bowls, cups, jars, jarlets, typical high-stemmed bowls and a few pithoi [56, 62, 66–68].

Wares, forming techniques and morphometric analyses

At Arslantepe ceramic wares have been conventionally distinguished since the 1970s on the basis of specific macroscopic hierarchical criteria, namely texture (coarse/semifine/fine), tempering material (chaff/grit/mixed), shaping techniques (handmade/wheel-finished), surface treatments (slipping/burnishing/smoothing) and colors (red-black/black/red/brown/light-colored) [52, 62, 64, 65]. Morphological criteria have been considered separately, at another level of analysis, and formed the basis for further functional observations. This classification statistically consolidated across decades thanks to the analysis of thousands of diagnostic sherds and complete vessels found in primary contexts of deposition [48, 49, 62, 64]. Interestingly, the correlation between shapes (morphological types) and wares increases through time. It is in fact during the LC5 that the strongest correspondence between pots with a specific shape and wares occurs, with only two exceptions: the high-stemmed bowls (Fig 2i) and small jarlets with an S-shaped/sinuous profile (Fig 2g), both realized in fine light-colored wheel-finished and red-black burnished ware. In the previous LC3-4 period most vessel shapes are invariably realized in either wheel-finished or handmade wares, the former being anyway a minority of the total assemblage [69]. The term “mass-produced”, conventionally adopted in Mesopotamian Archaeology, refers to specific categories of bowls produced on a large scale—usually hundreds or even thousands of items of the same vessel category in terms of shape, function, and approximate size—and found all together in the same contexts. This term therefore crosses technical, quantitative and typological criteria.

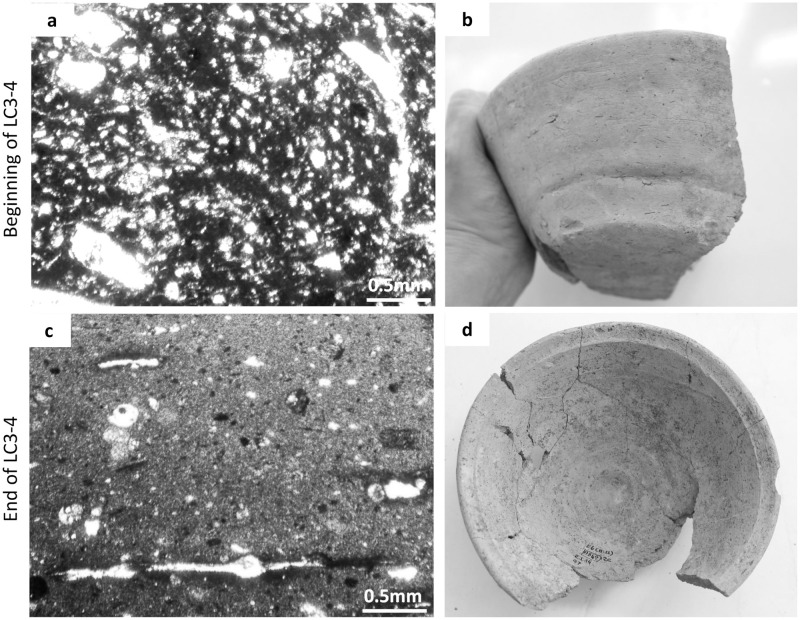

In the late 1960s and 1970s, Alba Palmieri already argued for the introduction and frequent use of rotating devices in the manufacture of LC3-4 pottery [70] and the introduction of the fast-wheel by the LC5 due to the recurrence on some vessel shapes of inner concentric grooves and underside string cut impressions [71]. Palmieri’s initial observations were then confirmed and broadened by other scholars working on the LC material from Arslantepe [48, 52, 62, 64, 69]. I cannot discuss this hypothesis in detail here, but following the more recent contributions on wheel-based forming techniques [72] I am currently investigating the LC repertoire. My recent work demonstrates that during the LC4 (end of period VII in the site sequence) the use of turning devices consolidates by entering progressively earlier stages of the forming sequence [73, 74]. This is especially evident for the mass-produced bowls at both a microscopic and macroscopic level (Fig 3). Microscopically, the temper fraction follows strongly oriented patterns and the clay matrix shows evidence of shear stresses. Macroscopically, concentric striations/grooves spread along the entire vessel profiles, the wall thickness gets gradually thinner towards the rim, profiles gain in symmetry, while linear discontinuities and anomalies in correspondence of structural joints decrease or even disappear.

Microscopic and macroscopic features of mass-produced bowls at the beginning and end of the LC3-4 phase, evidencing a diachronic increase in the use of the rotational kinetic energy.

Image: ÖAW-ÖAI / P. Fragnoli.

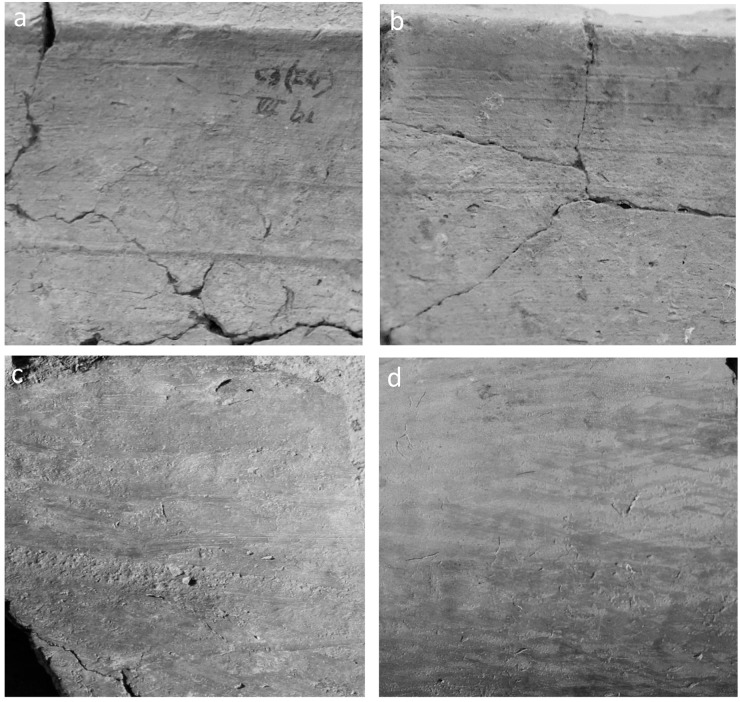

In this paper vessels were distinguished depending on whether or not they were produced with the help of rotating devices, whatever the stage of the forming sequence these devices entered in. These two large categories are here referred to as handmade and wheel-finished vessels, even though the latter might have combined different forming techniques. This broad categorization puts the emphasis on the most significant technical innovation of the period, i.e. the introduction of turning devices, and related hypotheses on craft specialization and standardization. At Arslantepe wheel-finished vessels are mainly distinguished by horizontal and parallel striations or grooves that might appear on the different surfaces of the vessel body (Fig 4). These diagnostic traces result from finishing, thinning, shaping or cutting vessels while turning. Striations might also occur on vessel surfaces without the use of any rotating devices due to finishing procedures like smoothing and burnishing. However, striations visibly differ depending on whether or not they were generated by the application of the rotational kinetic energy (Fig 5). On wheel-finished vessels striations appear as dense, fine, ribbed, continuous and homogeneous lines, which are evenly spaced from each other and organized in horizontal parallel concentric bands. Moreover, a typical fluidized surface microtopography is often associated with these features. The striations obtained without the rotational kinetic energy are instead much more heterogeneous both in shape and orientation [72: 236–240]. Further diagnostic features of wheel-finished vessels are regular wall thicknesses, stretched surfaces and strong symmetry of profiles.

a. LC3-4 handmade kitchen ware; b. LC3-4 wheel-finished kitchen ware; c. LC3-4 wheel-finished mass-produced bowl with potter’s mark; d. LC3-4 wheel-finished chaff-tempered smoothed ware; e. LC3-4 wheel-finished red-slipped burnished ware; f. LC 5 wheel-finished light-colored fine ware (internal side of the foot of a high-stemmed bowl; g. wheel-finished light-colored fine ware (internal side of a jarlet); h. LC5 wheel-finished mass-produced bowl; i. neck of a LC5 wheel-finished light-colored semifine ware large jar. Image: Archive of the Missione Archeologica Italiana in Anatolia Orientale (MAIAO).

Striations occurring with (a-b) or without (c-d) the use of rotating devices.

Image: ÖAW-ÖAI / P. Fragnoli.

To assess the morphological variability of the LC3-4 to LC5 pottery repertoire, Guarino and D’Anna calculated the coefficient of variation (CV) on the ratios between maximum diameter and height, rim diameter and maximum diameter, and rim diameter and height of specific vessel types [66, 71]. Usually, an assemblage of ceramics with CV below 10% is considered to have a low level of variability as the result of specialized potters [5, 18, 22, 27]. At Arslantepe most of the LC3-5 vessels present higher CVs (Table 1). Values indicating a higher standardization surprisingly recur in the handmade vessels, while the serial production of bowls with the help of rotating devices does not inevitably imply a decreased variability. Lastly, the LC5 does not mark an increase in standardization despite the stronger incidence of the rotational kinetic energy in the manufacturing process.

| Manufacturing | Vessel classes | Considered ratios | CV ranges | |

|---|---|---|---|---|

| LC3-4 | wheel-finished | serving/storage jars | Ø rim / Ø max | 9.37–21.30 |

| cooking pots | Ø rim / Ø max | 8.44–9.87 | ||

| Ø rim / height | 10.94–17.87 | |||

| mass-produced bowls | Ø rim / height | 9.57 | ||

| handmade | serving/storage jars | Ø rim / Ø max | 17.59 | |

| cooking pots | Ø rim / Ø max | 5.94–6.82 | ||

| LC5 | wheel-finished | mass-produced bowls | Ø rim / height | 13.06 |

| necked-jars | Ø max / height | 4.6–10.5 | ||

| Ø rim / Ø max | 13.1–17.8 | |||

| Ø rim / height | 11.9–22 | |||

| fine jarlets | Ø rim / height | 10.4–13.2 | ||

| Ø rim / Ø max | 10.7–11.7 | |||

| handmade | cooking pots | Ø max / height | 6.8–13.2 | |

| Ø rim / Ø max | 5.1–16.5 | |||

| monochrome/red-black burnished ware | Ø rim / height | 5.15–17.58 |

Geological setting and raw material supply

The site of Arslantepe (Fig 6) lies on Miocene lake sediments, mainly consisting of calcareous clays, limestones and sandstones [75]. Immediately northeast of the site, at a distance of 700 m, is the remnant of the Middle Miocene Orduzu volcanic suite [76] composed of rhyolites, trachyandesites, basaltic trachyandesites and quartz-micromonzonites [77]. Approximately 5.5 km further east we find the Late Cretaceous Baskil magmatics and the Maastrichtian to the Early Eocene Yüksekova/Elazığ complex, dominated by volcanic and intrusive rocks ranging from mafic to felsic affinities, i.e. gabbros, diorites, tonalities, monzonites, basaltic andesites, andesites, dacites and rhyolites [78, 79].

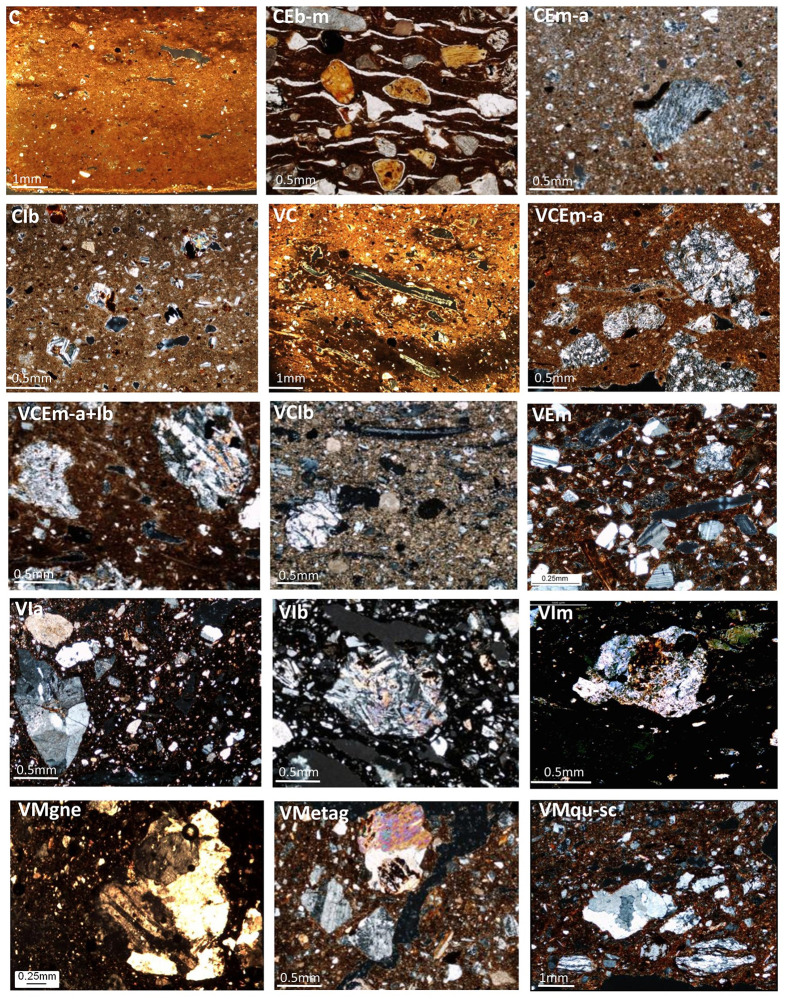

Selected micro-pictures illustrating the main petro-groups.

Image: ÖAW-ÖAI / P. Fragnoli.

More distant and spatially widespread are the units of the Antitaurus mountain chains that start rising 7 to 10 km south of the site. The western part of these units belongs to the Malatya metamorphics distinguished by Carboniferous to Triassic meta-carbonate rocks, mica schists, phyllites, slates, meta-clastic rocks and meta-cherts [80, 81]. The eastern part is instead dominated by the Late Cretaceous Ispendere ophiolites and the Middle Eocene Maden Complex. The former exhibit an intact ophiolitic sequence intruded by granites [82], the latter a volcanosedimentary sequence with conglomerates, sandstones, limestones, mudstones, spilitic lavas, radiolarites, cherts, altered basalts and andesites [80, 81, 83].

Most of the above-mentioned formations were exploited for producing vessels at Arslantepe, with distinct patterns according to the chronological phases and/or type of wares [84–86]. The variety of geological formations locally available [87] represents a double-edged sword from a methodological point of view and especially for minero-petrographic applications. On the one hand, we are able to outline precise strategies of raw material procurement within the local landscape; on the other, we often have difficulties in distinguishing local from imported vessels. To this end, thin section petrography is integrated with geochemical analyses of both vessels and local raw materials [84–86].

Sampling strategy and methods

The samples under investigation represent the variety of ceramic shapes and wares produced at the site along the entire Late Chalcolithic sequence (ca. 4700–3200 BCE). As illustrated above, within the assemblage of each period, wares have been macroscopically identified on the basis of the consistent co-occurrence of fabrics, manufacturing techniques, surface treatments, firing procedures, and, when present, decorations. Sampling strategies aimed at accounting for the duration of each period and the associated amount of materials recovered so far. This allows us to mitigate the cumulative blurring effect, namely the higher variability that production events generate along longer time-spans [36]. Thus, mostly represented here is the vast vessel repertoire of the long-lasting LC3-4 phase (97 samples). By contrast, the few samples (19) from the LC1-2 refer to a single context within the entire phase and are rather intended to act as reference for a non-standardized production [48, 49]. The assemblages of the following LC3-4 and LC5 phases (51 samples)—which provide us with evidence of economic centralization, intensification of production rates and introduction of the wheel—are instead those used in this paper to test the standardization hypothesis. At any rate, this study is intended as a first small-scale experiment aimed at testing the potential of diversity statistics in assessing craft standardization with the objective of being subsequently applied and adjusted to a wider sampling also including other geographic and chronological frameworks. The permission for pottery sampling and-analysis was kindly issued by the Turkish authorities.

Since the paper aims at assessing the uniformity of the local production modes, vessels of underrepresented foreign typology (e.g. the rare beveled rim bowls found at the site) or not matching geochemically and petrographically with local reference fields have been excluded [74, 84, 85]. The petrographic data used in this paper refer to 167 thin sections (Tables 2 and 3; Fig 6) that are grouped according to: 1) calcareous versus non-calcareous clay matrix; 2) the presence/absence of organic temper; 3) the geological origin of mineral and rock inclusions, which may refer to variegated volcanic, plutonic and metamorphic environments. Based on petrographic groupings, 60 representative samples were selected to be analyzed through wavelength-dispersive X-ray fluorescence (Table 5). Measurements were undertaken at the Archea Laboratory in Warsaw using the wavelength dispersive X-Ray Fluorescence spectrometer PANnalytical AXIOS. After being ignited at 900°C, 1.5-2g powder of each sample was melted with a lithium-borate mixture and cast into small discs. Major elements were normalized to a constant sum of 100% and trace elements under the detection limit (e.g. Y, Pb, Nb, Cu) were removed. Detailed descriptions of the petro-groups as well as “more traditional” bivariate and multivariate statistical elaborations of geochemical data have already been published in the contributions of the author indicated above and for this reason are not reported again here in detail. Petrography has been applied to a higher number of samples, since it has repeatedly proven to be a more eloquent indicator of local technological practices due to the coarseness of the vessels and the occurrence of variegated and well-delimited geological formations all around the site. The selected petrographic and geochemical data considered here cover the entire local spectrum, which was previously assessed in a wider sampling and along a longer chronological span. The assessment of the diversity parameters proposed in this paper does not require any particular statistical software as they can be easily performed on Excel (S1–S3 Tables).

| Sample | Phase | Ceramic ware | Petro-group |

|---|---|---|---|

| 126/14* | LC1-2 | handmade plain grit ware | NC |

| 127/14* | handmade plain grit ware | CIb | |

| 128/14* | handmade plain grit ware | NC | |

| 129/14* | handmade plain grit ware | CIb | |

| 130/14* | handmade plain ware | VIm | |

| 131/14* | handmade plain ware | NC | |

| 132/14* | handmade plain ware | NC | |

| 133/14* | handmade plain ware | VIa | |

| 134/14* | handmade burnished ware | NC | |

| 135/14* | handmade burnished ware | NC | |

| 136/14* | handmade burnished ware | NC | |

| 137/14* | handmade burnished ware | NC | |

| 138/14* | handmade burnished ware | VIm | |

| 139/14* | handmade mass-produced bowl | VIm | |

| 140/14* | handmade mass-produced bowl | NC | |

| 141/14* | handmade mass-produced bowl | VIm | |

| 142/14* | handmade plain ware | VIa | |

| 143/14* | handmade mass-produced bowl | NC | |

| 144/14* | handmade mass-produced bowl | NC | |

| 3638 | LC3-4 | wheel-finished red-slipped burnished ware | VCEm-a |

| 3639 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 3641 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 3642 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 3643 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 3644 | wheel-finished red-slipped burnished ware | VCIb | |

| 3645 | wheel-finished red-slipped burnished ware | VCIb | |

| 3646 | wheel-finished kitchen ware | VCIb | |

| 3647 | wheel-finished kitchen ware | VCIb | |

| 3648 | wheel-finished kitchen ware | VCEm-a+Ib | |

| 3649 | wheel-finished red-slipped burnished ware | VCIb | |

| 3650 | wheel-finished chaff-tempered smoothed ware | VCIb | |

| 3651 | wheel-finished chaff-tempered smoothed ware | VCIb | |

| 3654 | wheel-finished kitchen ware | VIb | |

| 3655 | handmade kitchen ware | VIb | |

| 3656 | wheel-finished mass-produced bowl | VCEm-a | |

| 3657 | wheel-finished mass-produced bowl | VCIb | |

| 3658 | wheel-finished mass-produced bowl | VCEm-a | |

| 3660 | wheel-finished mass-produced bowl | VCEm-a | |

| 3661 | wheel-finished mass-produced bowl | VCEm-a | |

| 3662 | wheel-finished mass-produced bowl | VCEm-a | |

| 3673 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 3674 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 3675 | wheel-finished red-slipped burnished ware | VCIb | |

| 3676 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 103/14 | wheel-finished chaff-tempered smoothed ware | VCIb | |

| 104/14 | wheel-finished red-slipped burnished ware | NC | |

| 105/14 | wheel-finished chaff-tempered smoothed ware | VIb | |

| 107/14 | wheel-finished chaff-tempered smoothed ware | VIb | |

| 159/14 | wheel-finished red-slipped burnished ware | VC | |

| 257/14 | wheel-finished chaff-tempered smoothed ware | VCEm-a+Ib | |

| 271/14 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 272/14 | handmade light-colored ware | VC | |

| 273/14 | handmade light-colored ware | VIb | |

| 274/14 | handmade red-black/monochrome burnished ware | NC | |

| 275/14 | handmade light-colored ware | NC | |

| 276/14 | handmade kitchen ware | VIb | |

| 277/14 | handmade kitchen ware | NC | |

| 300/14 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 301/14 | wheel-finished mass-produced bowl | VCEm-a | |

| 304/14 | wheel-finished mass-produced bowl | VC | |

| 305/14 | wheel-finished red-slipped burnished ware | VCIb | |

| 307/14 | wheel-finished kitchen ware | VMgne | |

| 309/14 | wheel-finished chaff-tempered smoothed ware | VIb | |

| 370/14 | wheel-finished chaff-tempered smoothed ware | VMgne | |

| 371/14 | wheel-finished chaff-tempered smoothed ware | VCEm-a+Ib | |

| 372/14 | wheel-finished chaff-tempered smoothed ware | VIb | |

| 375/14 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 376/14 | wheel-finished red-slipped burnished ware | VC | |

| 102/14 | wheel-finished red-slipped burnished ware | NC | |

| 106/14 | wheel-finished chaff-tempered smoothed ware | VCEm-a+Ib | |

| 108/14 | wheel-finished mass-produced bowl | VC | |

| 109/14 | wheel-finished mass-produced bowl | VCEm-a | |

| 155/14 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 156/14 | wheel-finished red-slipped burnished ware | VCIb | |

| 157/14 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 158/14 | wheel-finished red-slipped burnished ware | VC | |

| 160/14 | wheel-finished red-slipped burnished ware | VCIb | |

| 161/14 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 162/14 | wheel-finished red-slipped burnished ware | VC | |

| 163/14 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 258/14 | wheel-finished chaff-tempered smoothed ware | VCIb | |

| 259/14 | wheel-finished kitchen ware | VIb | |

| 260/14 | wheel-finished chaff-tempered smoothed ware | VIb | |

| 261/14 | wheel-finished kitchen ware | VEm | |

| 262/14 | handmade kitchen ware | VEm | |

| 278/14 | handmade kitchen ware | NC | |

| 279/14 | handmade light-colored ware | VCEm-a+Ib | |

| 280/14 | handmade kitchen ware | VMqu-sc | |

| 281/14 | wheel-finished chaff-tempered smoothed ware | VCEm-a+Ib | |

| 282/14 | wheel-finished light-colored fine ware | C | |

| 283/14 | wheel-finished light-colored fine ware | C | |

| 284/14 | wheel-finished mass-produced bowl | VC | |

| 285/14 | wheel-finished light-colored fine ware | C | |

| 286/14 | wheel-finished light-colored fine ware | C | |

| 287/14 | wheel-finished light-colored fine ware | VCEm-a+Ib | |

| 288/14 | wheel-finished light-colored fine ware | NC | |

| 289/14 | wheel-finished light-colored fine ware | C | |

| 290/14 | handmade red-black/monochrome burnished ware | NC | |

| 291/14 | handmade red-black/monochrome burnished ware | NC | |

| 293/14 | handmade red-black/monochrome burnished ware | NC | |

| 294/14 | handmade red-black/monochrome burnished ware | NC | |

| 295/14 | handmade red-black/monochrome burnished ware | NC | |

| 296/14 | handmade red-black/monochrome burnished ware | NC | |

| 299/14 | wheel-finished chaff-tempered smoothed ware | VEm | |

| 302/14 | wheel-finished mass-produced bowl | VCEm-a | |

| 303/14 | wheel-finished mass-produced bowl | VC | |

| 306/14 | wheel-finished chaff-tempered smoothed ware | VC | |

| 308/14 | wheel-finished red-slipped burnished ware | VCIb | |

| 366/14 | wheel-finished red-slipped burnished ware | VCEm-a+Ib | |

| 367/14 | handmade red-black/monochrome burnished ware | NC | |

| 368/14 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 369/14 | handmade light-colored ware | VC | |

| 373/14 | handmade kitchen ware | VMqu-sc | |

| 374/14 | wheel-finished chaff-tempered smoothed ware | VCEm-a+Ib | |

| 450/14 | wheel-finished light-colored fine ware | NC | |

| 310/14 | wheel-finished red-slipped burnished ware | VCEm-a | |

| 3595 | LC5 | handmade red-black/monochrome burnished ware | NC |

| 3558 | handmade red-black/monochrome burnished ware | NC | |

| 3560 | handmade red-black/monochrome burnished ware | NC | |

| 3594 | handmade red-black/monochrome burnished ware | NC | |

| 3554 | wheel-finished mass-produced bowl | VCEm-a | |

| 223/14 | handmade red-black/monochrome burnished ware | NC | |

| 225/14 | handmade red-black/monochrome burnished ware | NC | |

| 227/14 | handmade red-black/monochrome burnished ware | NC | |

| 230/14 | handmade red-black/monochrome burnished ware | NC | |

| 232/14 | handmade red-black/monochrome burnished ware | NC | |

| 2/2015 | handmade red-black/monochrome burnished ware | NC | |

| 4/2015 | handmade red-black/monochrome burnished ware | NC | |

| 5/2015 | handmade red-black/monochrome burnished ware | NC | |

| 3593 | handmade red-black/monochrome burnished ware | VCEm | |

| 3559 | handmade red-black/monochrome burnished ware | VCEm | |

| 224/14 | handmade red-black/monochrome burnished ware | VMgne | |

| 229/14 | handmade red-black/monochrome burnished ware | VMgne | |

| 231/14 | handmade red-black/monochrome burnished ware | VMgne | |

| 234/14 | handmade red-black/monochrome burnished ware | VMgne | |

| 235/14 | handmade red-black/monochrome burnished ware | VMgne | |

| 228/14 | handmade red-black/monochrome burnished ware | NC | |

| 236/14 | handmade red-black/monochrome burnished ware | VMmetag | |

| 1/2015 | handmade red-black/monochrome burnished ware | VMmetag | |

| 3/2015 | handmade red-black/monochrome burnished ware | VMmetag | |

| 253/14* | handmade kitchen ware | NC | |

| 254/14* | handmade kitchen ware | NC | |

| 250/14* | handmade kitchen ware | VMmetag | |

| 255/14* | handmade kitchen ware | VMmetag | |

| 249/14* | handmade kitchen ware | VMgne | |

| 252/14* | handmade kitchen ware | VMgne | |

| 247/14* | wheel-finished light-colored semifine ware | VCEm-a+Ib | |

| 3554 | wheel-finished mass-produced bowl | VCEm-a | |

| 3555 | wheel-finished light-colored semifine ware | VCEm-a | |

| 241/14* | wheel-finished light-colored fine ware | VCEm-a | |

| 240/14* | wheel-finished light-colored fine ware | VCIb | |

| 242/14* | wheel-finished light-colored fine ware | VCIb | |

| 3548 | wheel-finished light-colored fine ware | CIb | |

| 3600 | wheel-finished light-colored fine ware | CEb-m | |

| 248/14* | wheel-finished light-colored semifine ware | CEb-m | |

| 3551 | wheel-finished light-colored fine ware | CEm-a | |

| 239/14* | wheel-finished light-colored fine ware | CEm-a | |

| 3550 | wheel-finished light-colored fine ware | CIb | |

| 238/14* | wheel-finished light-colored fine ware | CIb | |

| 3601 | wheel-finished light-colored fine ware | NC | |

| COLL206/16* | wheel-finished mass-produced bowl | VC | |

| COLL202/16* | wheel-finished mass-produced bowl | VCEm-a+Ib | |

| COLL222/16* | wheel-finished mass-produced bowl | VCEm-a+Ib | |

| COLL208/16* | wheel-finished mass-produced bowl | VC | |

| COLL163/16* | wheel-finished light-colored semifine ware | VCEm-a+Ib | |

| COLL219/16* | wheel-finished light-colored semifine ware | VCEm-a+Ib | |

| COLL188/16* | wheel-finished light-colored fine ware | VCIb |

Each petrographic group is mentioned according to the following acronyms: V = organic tempered pastes; C = calcareous clay; E, M and I = Inclusions of effusive, metamorphic and intrusive origin; b, m, a = basic, intermediate and acid composition; for the metamorphic rocks gne, metag and qu-sc are abbreviations of gneiss, metagabbro and quartz-schist. NC (not classifiable) refers to petro-loners. The samples marked with an asterisk are new, while the other ones have been already published [74, 84, 85].

| Petro-group | Main inclusions | Inclusion max. size/amount |

|---|---|---|

| C | ca, for, qu, bt | 1.4mm/7% |

| CEb-m | ca, pl, qu, basaltic andesite, bt, qu-kfds aggregate, amph, cpx, ox, mu | 0.7mm/15% |

| CEm-a | ca, trachyte-rhyolite, limestone, pl, ox, mu, amph, bt | 1.4mm/7% |

| CIb | gabbro, pl, ca, for | 2mm/10% |

| VC | veg, qu, ca, pl | 3.3mm/7% |

| VCEm | veg, ca, pl, andesite, amph, bt, cpx, pumice, qu, ox | 2mm/25% |

| VCEm-a | veg, ca, trachyte-rhyolite, limestone, qu, pl, ox, amph, bt, mu, sandstone | 3.7mm/10% |

| VCEm-a+Ib | veg, ca, trachyte-rhyolite, gabbro, pl, qu, limestone, amph, ox, sandstone | 5.6mm/10% |

| VCIb | veg, ca, gabbro, pl, ox, cpx, trachyte-rhyolite, limestone, sandstone, for, granite, qu, opx | 7mm/15% |

| VEm | veg, pl, andesite, amph, bt, qu, cpx, pumice, opx | 3.7mm/25% |

| VIa | veg, granite, qu, kfds, pl, bt, amph | 2mm/15% |

| VIb | veg, gabbro, pl, ox, trachyte-rhyolite, qu, granite | 7.8mm/20% |

| VIm | veg, diorite, qu, pl, kfds, amph | 4mm/20% |

| VMgne | veg, gneiss, qu, amph, pl, bt, kfds | 5mm/20% |

| VMmetag | veg, metagabbro, cpx, gneiss, amphibolite, qu, pl, kfds | 5.17mm/24% |

| VMqu-sc | veg, mu-schist, qu-schist, mu, qu, bt, ox | 4.8mm/30% |

The types of inclusions are listed in decreasing order of importance. Abbreviations: veg = vegetal fibers; ca = calcite; pl = plagioclase; qu = quartz; bt = biotite; amph = amphibole; cpx = clinopyroxene; mu = muscovite; for = foraminifera; Kfds = K-feldspar; ox = oxide; opx = orthopyroxene. Further details have been reported in previous publications [74, 84, 85].

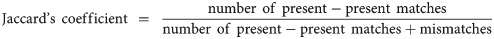

Assessing the variability of metric data: Pottery elemental concentrations

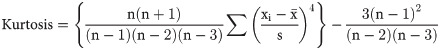

The geochemical variability was quantified by calculating the coefficient of variation (CV) for each element concentration measured through wavelength-dispersive X-ray fluorescence, namely SiO2, TiO2, Fe2O3, MnO, MgO, CaO, Na2O, K2O, P2O5, V, Cr, Ni, Zn, Rb, Sr, Zr and Ba. The CV is defined as the ratio between standard deviation and mean, often multiplied by 100 to be expressed as a percentage. The higher the CV, the more variable the dataset. The CV has been commonly used not only in natural sciences, medicine and psychology but also in archaeological studies on vessel formal and dimensional standardization. As shown by the latter, it differs from other indexes in providing reliable measures of variability independently of sample size and the measure of scale [22, 88–90]. Blackman and colleagues [36] also successfully used the CV to assess the geochemical variability of the 3rd millennium mass-produced bowls from Tell Leilan in northeast Syria.

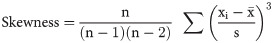

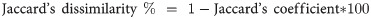

Following a method proposed by Eerkens and Bettinger [22] for assessing the formal standardization of various archaeological artifacts, a scatter plot includes the mean and standard deviation of each element upon which the regression line is plotted. The regression line slopes vary according to the data variability: steeper slopes denote more variation in elemental concentrations. Furthermore, skewness and kurtosis were taken into account to estimate to what extent the data diverge from a normal distribution. In some studies on vessel formal standardization, these criteria have proven to be even more efficient than the CV to distinguish different levels of potters’ skills [90]. The skewness refers to the degree of distortion from a symmetrical data distribution, while the kurtosis measures the tailedness of this distribution, providing an indication of the presence of outliers. The closer to zero values the skewness and kurtosis are, the more normal is the distribution of data. Both skewness and kurtosis were calculated via the formulas available on Excel based on Fisher’s coefficient:

The CVs calculated separately on each element have the disadvantage of overlooking the correlations between elemental patterns existing in ceramic artifacts. To obviate this, a series of variation matrixes (S1 Table) were produced following the method introduced by Aitchison [91, 92] and further developed for pottery analysis by Buxeda i Garrigós and Kilikoglou [37, 93]. Variation matrixes are defined by the variances of the natural log-ratios calculated on every pair of elements present in the data set. From the variation matrix one can calculate the total variation, which quantifies the variability of the data set and is also related to the Euclidean distances among all specimens [94]. The total variation is defined as the sum of all the variances in the variation matrix divided by two times the number of elements determined. The variation matrix can also be used to determine the variance of an element, which is equal to the sum of the variances calculated on all the log-ratios that use this element as divisor. This value gives an estimate of the contribution of this element to the total variation of the data set [91, 93]. In ceramic studies the total variation has frequently been applied to estimate intra-deposit variations, post-depositional alterations as well as the monogenic vs. polygenic nature of the data set. However, it is rarely coupled with thin section petrography to assess the level of standardization of raw material procurement and processing.

Assessing the variability of non-metric data: Pottery petrographic grouping

Petrographic analyses of archaeological vessels usually aim at grouping thin sections into reference groups that ideally represent the ceramic pastes prepared in a certain way and place. The results are non-metric classifications similar to those obtained through typological methods. To assess the variability of such non-metric classification I applied three necessary and inextricably linked properties of diversity, which are employed across a full range of disciplines according to different degrees of prioritization and terminologies [95–97]. Here I will call these properties richness, evenness, and disparity (Fig 7). Richness can be also referred to as “variety”, and considers the number of categories—represented by petro-groups in this paper—in which elements are sorted. Evenness quantifies how equal is the distribution of elements across categories. In the present case it expresses how ceramic thin sections are distributed into each petro-group. Thus, evenness is analogous to statistical variance and can also be defined as “balance” or “concentration”. Ecological studies tend to focus on questions of richness and evenness due to the occurrence of well-established taxonomic schemes [96]. The concept of disparity—taken from paleontology and extensively used in conservation biology—indicates to what extent categories, for instance petro-groups, are different from each other, and is usually based on some form of distance measure. Typically, the greater the richness, evenness and disparity, the greater the diversity.

a. Mean of the CVs calculated for each element within each LC sub-phase; b. Relationships between mean (x-axis) and standard deviation (y-axis) for all chemical elements within each LC sub-phase.

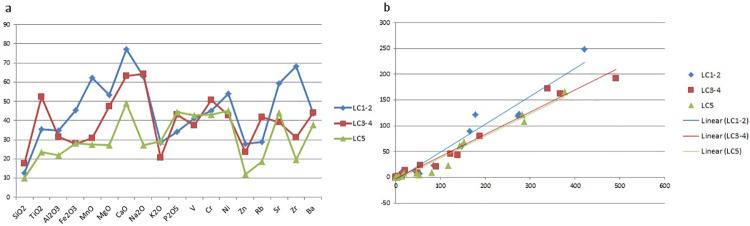

To quantify richness, evenness and variety I applied several indexes to the petrographic classification (Table 4). As for richness, I first considered the percentage of petro-loners. Petro-loners are composed of minerals and rocks of all local origin but differently combined with each other and in distinct grain-size distributions compared to the samples classified into petro-groups. In other words, these are vessels produced with different local deposits and/or recipes. Thus, petro-loners are random local recipes, which are comparable to unica in taxonomic classifications. Within single categories (e.g. periods, wares, manufacturing techniques) petro-groups that are represented by only one sample have been counted as petro-loners, even though they share features with samples outside the considered category. For instance, the handmade kitchen ware 262/14 is a loner within the handmade wares of the LC3-4, but not within the LC3-4 as a whole, since in this period two wheel-finished vessels (samples 261/14 and 299/14) present the same recipe (petro-group VEm). The richness was also quantified through the Menhinick’s and Shannon’s indexes (S2 Table), both commonly adopted in the ecological literature as a measure of biodiversity [98]. The Mehinick’s index is a simple species counting that attempts to reduce the effect of sample size on richness quantification, i.e. increased richness with larger sampling, by dividing the number of species recorded by the number of individuals in the sample. It is given here by the number of petro-groups divided the square root of the number of thin sections analyzed. The Shannon’s index was originally used within information theory to measure the entropy contained in a text based on the number and abundance of letter types [99]. The idea behind ecological applications is that the diversity of a community is similar to the amount of information in a code or message. For the purpose of calculations, the number of samples recurring in each recipe, including both petro-groups and loners, was divided by the total number of samples; this proportion was multiplied by its natural logarithm; the resulting product was summed across recipes and multiplied by -1:

| Richness | % petro-loners |

| Menhinick’s index | |

| Shannon’s index | |

| Evenness | Highest disparity in recipe abundance |

| Average number of samples per petro-group | |

| Pielou’s index | |

| Shannon’s index | |

| Disparity | Jaccard’s dissimilarity % |

Since Shannon’s index considers not only the number of petro-groups but also the distribution of thin sections into petro-groups, it has also been considered to assess the evenness. Evenness was also evaluated through the relative abundance of each recipe and especially through the maximum difference in abundance between the most and the least represented recipe. Both petro-groups and petro-loners were counted as more and less established recipes, respectively. In order to assess the evenness of only well-established recipes a further parameter was calculated by excluding the petro-loners, namely the average number of samples per petro-group. Last but not least, I calculated the Pielou’s index (S2 Table), which is obtained by dividing the Shannon’s index with the highest possible value this index could have in case of highest variability. Disparity measures are generally based on distances or dissimilarity coefficients, which indicate how dissimilar two cases are considering simultaneously all the variables for which they have been defined [100]. Dissimilarity coefficients are obtained by subtracting 1 from similarity coefficients. There are different similarity/dissimilarity coefficients according to the considered variables, of either a quantitative or qualitative nature. In this paper, I took into account and converted into percent the Jaccard distance based on the presence and absence of some basic ingredients that may occur across different petro-groups (S3 Table):

These basic ingredients correspond to the main discriminating criteria adopted for grouping ceramic thin sections [85] and are registered in the acronyms of each petro-group (Table 2). These are organic temper (V), calcareous matrix (C), granite (Ia), diorite (Im), quartz-schist (qu-sc), gabbro (Ib), trachyte-rhyolite (Em-a), andesite (Em), basaltic andesite (Eb-m), metagabbro (metag) and gneiss (gne). The Jaccard’s distance has not been calculated on petro-loners, which in a sense already represent an index of maximal disparity due to their lack of affinity with any other sample. While the assessment of disparity finds many applications in archaeology (e.g. cemetery analyses), richness and evenness are rarely considered even in specialized handbooks [100]. However, these latter indexes allow us to further nuance the concept of diversity and could be successfully applied to any kind of archaeological classification—e.g. morpho-functional, typological and stylistic—beyond standardization studies.

In summary, a high standardization of ceramic recipes should ideally correspond to low values of all diversity indexes (i.e. Menhinick’s, Shannon’s, Pielou’s and Jaccard’s), a reduced number of petro-loners, an unequal distribution of samples across petro-groups, and a high average number of samples per petro-groups.

Results

Geochemical homogenization as a result of production serialization

In order to compare each Late Chalcolithic phase—i.e. LC1-2 (Arslantepe VIII), LC3-4 (VII) and LC5 (VI A)—I plotted on a line graph the mean of the CVs calculated for each element (Table 5 and Fig 7a) and I found that the geochemical variability tends to decrease throughout the LC period in terms of both major and trace elements. An identical trend can be inferred from the scatterplot (Fig 7b) relating the standard deviation with the mean of all elements: the regression line of the LC1-2 is steeper compared to those of the following phases, suggesting a higher compositional variability. The geochemical homogenization across the Late Chalcolithic becomes even more pronounced when considering the elemental variance and the total variation (Fig 8, Table 5). The elements responsible for the highest variability of the first Late Chalcolithic phase are Al2O3, TiO2, MnO, MgO, Na2O and Zr.

| Sample | Phase | Ceramic ware | SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | V | Cr | Ni | Zn | Rb | Sr | Zr | Ba |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 134/14 | LC1-2 | handmade burnished ware | 51.03 | 0.70 | 12.39 | 7.48 | 0.11 | 6.64 | 17.31 | 1.16 | 3.00 | 0.18 | 147 | 531 | 323 | 103 | 59 | 487 | 103 | 226 |

| 201/15 | handmade mass-produced bowls | 45.49 | 0.59 | 10.90 | 5.21 | 0.07 | 5.38 | 28.39 | 1.04 | 2.67 | 0.26 | 110 | 287 | 223 | 92 | 40 | 814 | 121 | 248 | |

| 208/15 | handmade mass-produced bowls | 48.42 | 1.24 | 13.17 | 7.13 | 0.09 | 4.11 | 21.20 | 1.47 | 2.91 | 0.25 | 130 | 291 | 177 | 104 | 43 | 457 | 124 | 465 | |

| 210/15 | handmade burnished ware | 63.94 | 1.32 | 27.37 | 1.98 | 0.01 | 0.41 | 3.64 | 0.11 | 1.08 | 0.15 | 106 | 161 | 63 | 37 | 16 | 70 | 473 | 65 | |

| 211/15 | handmade burnished ware | 60.49 | 0.81 | 20.43 | 5.76 | 0.04 | 1.91 | 4.95 | 3.28 | 2.17 | 0.16 | 91 | 147 | 79 | 67 | 55 | 484 | 163 | 307 | |

| 212/15 | handmade plain ware | 56.09 | 1.42 | 18.42 | 12.19 | 0.18 | 2.91 | 4.74 | 1.89 | 1.92 | 0.23 | 263 | 305 | 156 | 107 | 46 | 201 | 166 | 210 | |

| 215/15 | handmade mass-produced bowls | 46.99 | 0.60 | 11.08 | 5.29 | 0.08 | 5.04 | 26.49 | 1.02 | 3.14 | 0.29 | 110 | 298 | 218 | 80 | 46 | 646 | 127 | 379 | |

| 221/15 | handmade plain ware | 58.62 | 0.87 | 18.22 | 9.70 | 0.17 | 3.67 | 4.03 | 2.35 | 2.28 | 0.09 | 211 | 177 | 83 | 88 | 45 | 204 | 147 | 279 | |

| mean | 53.88 | 0.94 | 16.50 | 6.84 | 0.09 | 3.76 | 13.84 | 1.54 | 2.39 | 0.20 | 146.14 | 274.76 | 165.20 | 84.80 | 43.75 | 420.48 | 177.86 | 272.34 | ||

| dev std | 6.85 | 0.34 | 5.72 | 3.10 | 0.06 | 2.00 | 10.69 | 0.97 | 0.69 | 0.07 | 60.27 | 123.42 | 89.16 | 23.60 | 12.68 | 248.83 | 121.16 | 119.19 | ||

| CV | 12.71 | 35.51 | 34.67 | 45.28 | 62.19 | 53.29 | 77.22 | 62.78 | 28.67 | 33.99 | 41.24 | 44.92 | 53.97 | 27.83 | 28.99 | 59.18 | 68.12 | 43.77 | ||

| skewness | 0.19 | 0.43 | 0.93 | 0.33 | 0.27 | -0.34 | 0.32 | 0.55 | -0.96 | -0.30 | 1.35 | 1.26 | 0.54 | -1.28 | -1.48 | 0.11 | 2.65 | -0.10 | ||

| kurtosis | -1.65 | -1.79 | 0.39 | 0.53 | -0.64 | -0.27 | -2.10 | 0.61 | 0.66 | -1.07 | 0.86 | 2.28 | -0.33 | 1.46 | 3.53 | -0.77 | 7.23 | 0.85 | ||

| variance | 7.94 | 10.43 | 11.61 | 6.85 | 13.27 | 11.22 | 15.29 | 16.96 | 5.18 | 7.41 | 7.65 | 6.66 | 7.67 | 4.96 | 5.41 | 11.15 | 15.89 | 7.15 | ||

| total variation | 4.80 | |||||||||||||||||||

| 301/14 | LC3-4 | wheel-finished mass-produced bowl | 44.41 | 0.44 | 9.18 | 3.95 | 0.07 | 4.03 | 33.25 | 0.91 | 3.37 | 0.39 | 81 | 306 | 154 | 69 | 53 | 746 | 111 | 263 |

| 304/14 | wheel-finished mass-produced bowl | 37.46 | 0.53 | 8.89 | 4.58 | 0.08 | 3.55 | 41.24 | 0.42 | 3.00 | 0.26 | 77 | 394 | 146 | 79 | 32 | 478 | 117 | 236 | |

| 109/14 | wheel-finished mass-produced bowl | 45.75 | 0.56 | 10.72 | 5.02 | 0.08 | 4.57 | 29.68 | 0.75 | 2.64 | 0.23 | 92 | 515 | 182 | 67 | 55 | 542 | 130 | 263 | |

| 285/14 | wheel-finished mass-produced bowl | 39.16 | 0.41 | 8.82 | 4.76 | 0.06 | 4.25 | 38.02 | 0.67 | 3.57 | 0.27 | 76 | 315 | 238 | 106 | 29 | 884 | 96 | 375 | |

| 302/14 | wheel-finished mass-produced bowl | 48.41 | 0.50 | 11.43 | 5.10 | 0.08 | 4.56 | 25.36 | 0.89 | 3.37 | 0.30 | 74 | 223 | 211 | 93 | 56 | 475 | 115 | 275 | |

| 303/14 | wheel-finished mass-produced bowl | 38.48 | 0.50 | 8.70 | 4.84 | 0.07 | 5.71 | 38.78 | 0.35 | 2.39 | 0.17 | 91 | 604 | 246 | 83 | 39 | 541 | 109 | 195 | |

| 192/15 | wheel-finished mass-produced bowl | 49.35 | 0.50 | 11.27 | 4.53 | 0.08 | 4.46 | 25.27 | 1.16 | 3.06 | 0.31 | 70 | 329 | 162 | 60 | 64 | 549 | 127 | 331 | |

| 193/15 | wheel-finished mass-produced bowl | 33.55 | 0.30 | 6.36 | 4.45 | 0.07 | 10.54 | 43.00 | 0.23 | 1.37 | 0.12 | 71 | 634 | 257 | 69 | 21 | 558 | 53 | 399 | |

| 171/15 | wheel-finished mass-produced bowl | 33.94 | 0.35 | 6.56 | 4.89 | 0.08 | 10.28 | 42.17 | 0.29 | 1.22 | 0.21 | 90 | 786 | 286 | 67 | 23 | 682 | 65 | 118 | |

| 271/14 | wheel-finished red-slipped burnished ware | 62.29 | 0.96 | 19.03 | 8.93 | 0.15 | 2.62 | 0.89 | 1.22 | 3.70 | 0.22 | 160 | 307 | 147 | 137 | 104 | 109 | 189 | 685 | |

| 300/14 | wheel-finished red-slipped burnished ware | 37.01 | 0.64 | 8.46 | 5.02 | 0.08 | 8.27 | 37.70 | 0.76 | 1.92 | 0.14 | 116 | 329 | 244 | 76 | 37 | 770 | 101 | 218 | |

| 103/14 | wheel-finished red-slipped burnished ware | 48.28 | 1.69 | 13.42 | 7.64 | 0.10 | 5.25 | 18.87 | 1.95 | 2.52 | 0.29 | 201 | 226 | 171 | 100 | 50 | 636 | 164 | 457 | |

| 157/14 | wheel-finished red-slipped burnished ware | 44.95 | 0.92 | 11.63 | 6.25 | 0.08 | 6.25 | 25.36 | 1.53 | 2.79 | 0.22 | 100 | 326 | 239 | 93 | 31 | 518 | 108 | 381 | |

| 160/14 | wheel-finished red-slipped burnished ware | 43.46 | 1.16 | 10.76 | 6.39 | 0.08 | 9.25 | 24.85 | 1.40 | 2.47 | 0.19 | 152 | 549 | 232 | 102 | 29 | 568 | 133 | 284 | |

| 161/14 | wheel-finished red-slipped burnished ware | 47.26 | 0.54 | 10.49 | 5.02 | 0.08 | 5.72 | 26.73 | 0.91 | 3.05 | 0.18 | 90 | 545 | 243 | 88 | 57 | 533 | 121 | 293 | |

| 162/14 | wheel-finished red-slipped burnished ware | 42.47 | 0.51 | 9.31 | 5.37 | 0.09 | 6.38 | 32.19 | 0.55 | 2.93 | 0.20 | 98 | 526 | 301 | 95 | 39 | 753 | 109 | 239 | |

| 163/14 | wheel-finished red-slipped burnished ware | 45.12 | 0.42 | 9.05 | 4.58 | 0.07 | 6.96 | 29.79 | 0.98 | 2.86 | 0.16 | 79 | 588 | 274 | 97 | 47 | 669 | 97 | 260 | |

| 308/14 | wheel-finished red-slipped burnished ware | 48.33 | 1.28 | 12.98 | 6.62 | 0.08 | 3.64 | 21.56 | 1.42 | 3.39 | 0.70 | 154 | 392 | 191 | 84 | 48 | 473 | 155 | 237 | |

| 310/14 | wheel-finished red-slipped burnished ware | 40.97 | 0.40 | 8.59 | 4.83 | 0.08 | 8.41 | 33.02 | 0.73 | 2.81 | 0.15 | 71 | 360 | 298 | 93 | 28 | 677 | 83 | 354 | |

| 282/14 | wheel-finished light-colored fine ware | 40.84 | 0.43 | 8.79 | 6.00 | 0.09 | 7.76 | 32.20 | 0.86 | 2.63 | 0.41 | 103 | 427 | 358 | 99 | 25 | 802 | 95 | 404 | |

| 284/14 | wheel-finished light-colored fine ware | 43.68 | 0.53 | 9.23 | 5.03 | 0.10 | 4.99 | 32.63 | 0.53 | 3.00 | 0.28 | 90 | 592 | 230 | 88 | 43 | 608 | 117 | 247 | |

| 286/14 | wheel-finished light-colored fine ware | 46.75 | 0.63 | 10.65 | 6.33 | 0.13 | 5.84 | 25.92 | 0.45 | 2.98 | 0.31 | 126 | 332 | 287 | 106 | 44 | 535 | 111 | 715 | |

| 287/14 | wheel-finished light-colored fine ware | 51.34 | 1.10 | 14.71 | 7.22 | 0.09 | 4.60 | 15.88 | 1.81 | 3.06 | 0.19 | 141 | 222 | 161 | 111 | 45 | 335 | 112 | 462 | |

| 288/14 | wheel-finished light-colored fine ware | 54.83 | 0.99 | 16.80 | 10.26 | 0.14 | 7.33 | 5.75 | 1.35 | 2.34 | 0.20 | 168 | 345 | 308 | 108 | 63 | 115 | 93 | 457 | |

| 105/14 | wheel-finished chaff-tempered ware | 48.98 | 1.52 | 13.63 | 7.40 | 0.10 | 5.11 | 18.55 | 1.64 | 2.79 | 0.27 | 167 | 249 | 194 | 89 | 45 | 598 | 164 | 312 | |

| 257/14 | wheel-finished chaff-tempered ware | 61.63 | 1.22 | 18.18 | 6.91 | 0.09 | 2.46 | 3.76 | 2.72 | 2.83 | 0.20 | 122 | 156 | 87 | 72 | 74 | 329 | 194 | 383 | |

| 106/14 | wheel-finished chaff-tempered ware | 54.89 | 0.92 | 14.00 | 5.89 | 0.08 | 3.40 | 15.31 | 1.85 | 3.36 | 0.31 | 113 | 266 | 154 | 78 | 74 | 510 | 147 | 308 | |

| 258/14 | wheel-finished chaff-tempered ware | 49.21 | 1.74 | 14.68 | 7.48 | 0.10 | 3.72 | 18.05 | 2.20 | 2.59 | 0.24 | 180 | 197 | 126 | 87 | 48 | 597 | 185 | 295 | |

| 260/14 | wheel-finished chaff-tempered ware | 51.66 | 1.68 | 14.46 | 7.68 | 0.11 | 4.56 | 14.29 | 2.23 | 2.88 | 0.45 | 201 | 300 | 187 | 99 | 54 | 544 | 167 | 275 | |

| 281/14 | wheel-finished chaff-tempered ware | 62.09 | 1.26 | 18.07 | 6.69 | 0.09 | 2.57 | 3.87 | 2.89 | 2.31 | 0.17 | 119 | 133 | 72 | 70 | 78 | 347 | 217 | 413 | |

| 272/14 | handmade light-colored ware | 52.33 | 0.82 | 13.03 | 6.17 | 0.07 | 3.15 | 20.21 | 1.01 | 2.95 | 0.26 | 136 | 314 | 140 | 91 | 58 | 356 | 167 | 377 | |

| 273/14 | handmade light-colored ware | 53.25 | 1.76 | 15.51 | 7.98 | 0.08 | 2.98 | 13.48 | 2.22 | 2.54 | 0.20 | 183 | 204 | 98 | 96 | 61 | 392 | 196 | 264 | |

| 277/14 | handmade kitchen ware | 55.58 | 1.56 | 17.57 | 12.66 | 0.20 | 3.68 | 4.25 | 1.90 | 2.22 | 0.37 | 265 | 191 | 112 | 160 | 42 | 223 | 161 | 433 | |

| 262/14 | handmade kitchen ware | 60.48 | 0.80 | 20.47 | 5.07 | 0.09 | 2.27 | 5.02 | 3.52 | 2.15 | 0.13 | 85 | 142 | 63 | 58 | 89 | 477 | 175 | 316 | |

| 278/14 | handmade kitchen ware | 48.97 | 0.65 | 11.22 | 7.45 | 0.14 | 4.11 | 23.80 | 0.45 | 3.00 | 0.20 | 134 | 643 | 291 | 106 | 51 | 435 | 95 | 661 | |

| 280/14 | handmade kitchen ware | 64.37 | 1.02 | 18.28 | 6.45 | 0.05 | 2.98 | 1.25 | 1.18 | 4.18 | 0.23 | 144 | 223 | 167 | 130 | 128 | 205 | 225 | 514 | |

| 307/14 | wheel-finished kitchen ware | 63.16 | 0.56 | 15.65 | 6.62 | 0.10 | 3.19 | 5.74 | 1.42 | 3.43 | 0.14 | 152 | 235 | 116 | 69 | 84 | 169 | 141 | 326 | |

| 259/14 | wheel-finished kitchen ware | 56.90 | 2.02 | 18.40 | 8.73 | 0.11 | 2.67 | 5.35 | 3.26 | 2.31 | 0.25 | 182 | 118 | 66 | 83 | 63 | 401 | 231 | 308 | |

| 261/14 | wheel-finished kitchen ware | 59.84 | 0.84 | 20.92 | 5.71 | 0.09 | 1.97 | 4.82 | 3.05 | 2.29 | 0.49 | 93 | 127 | 83 | 68 | 70 | 476 | 179 | 417 | |

| 274/14 | handmade red-black/monochrome burnished ware | 63.02 | 0.91 | 17.01 | 8.06 | 0.08 | 1.92 | 4.70 | 0.73 | 3.23 | 0.32 | 138 | 167 | 98 | 80 | 80 | 90 | 158 | 1002 | |

| 291/14 | handmade red-black/monochrome burnished ware | 62.91 | 0.66 | 20.19 | 4.43 | 0.05 | 1.70 | 3.86 | 3.15 | 2.69 | 0.36 | 60 | 79 | 53 | 65 | 84 | 460 | 159 | 301 | |

| mean | 49.69 | 0.88 | 13.10 | 6.32 | 0.09 | 4.82 | 20.64 | 1.40 | 2.78 | 0.26 | 122.93 | 339.38 | 187.10 | 89.42 | 54.75 | 491.76 | 138.27 | 367.17 | ||

| dev std | 8.71 | 0.46 | 4.11 | 1.77 | 0.03 | 2.28 | 13.06 | 0.90 | 0.57 | 0.11 | 45.85 | 172.50 | 79.71 | 20.98 | 22.87 | 191.51 | 43.03 | 161.84 | ||

| CV | 17.53 | 52.42 | 31.39 | 28.00 | 30.70 | 47.34 | 63.26 | 64.10 | 20.60 | 43.08 | 37.29 | 50.83 | 42.60 | 23.47 | 41.78 | 38.94 | 31.12 | 44.08 | ||

| skewness | 0.08 | 0.85 | 0.31 | 1.42 | 2.06 | 0.91 | 0.01 | 0.83 | -0.42 | 1.82 | 0.91 | 0.72 | 0.11 | 1.15 | 0.99 | -0.35 | 0.31 | 1.99 | ||

| kurtosis | -0.89 | -0.33 | -1.07 | 2.95 | 5.85 | 0.21 | -1.24 | -0.24 | 1.23 | 5.02 | 0.73 | -0.25 | -0.92 | 2.19 | 1.40 | -0.11 | -0.51 | 5.34 | ||

| variance | 4.36 | 7.35 | 5.51 | 4.47 | 4.64 | 7.61 | 21.76 | 11.82 | 4.58 | 5.89 | 5.23 | 8.99 | 7.85 | 4.27 | 7.00 | 9.02 | 5.43 | 6.26 | ||

| total variation | 3.67 | |||||||||||||||||||

| 239/14 | LC5 | wheel-finished light-colored fine ware | 49.76 | 0.63 | 11.88 | 5.15 | 0.09 | 4.36 | 23.36 | 1.18 | 3.42 | 0.16 | 98 | 250 | 202 | 70 | 58 | 532 | 120 | 340 |

| 241/14 | wheel-finished light-colored fine ware | 44.62 | 0.40 | 9.08 | 4.41 | 0.07 | 7.00 | 30.21 | 1.04 | 3.01 | 0.16 | 50 | 542 | 260 | 91 | 33 | 554 | 87 | 514 | |

| 242/14 | wheel-finished light-colored fine ware | 49.18 | 0.71 | 11.64 | 5.62 | 0.09 | 5.00 | 22.47 | 1.20 | 3.84 | 0.26 | 101 | 315 | 200 | 91 | 59 | 508 | 123 | 403 | |

| 247/14 | wheel-finished light-colored semifine ware | 45.85 | 0.60 | 10.55 | 5.10 | 0.09 | 5.52 | 28.20 | 1.32 | 2.49 | 0.28 | 107 | 413 | 247 | 77 | 50 | 640 | 109 | 278 | |

| 248/14 | wheel-finished light-colored semifine ware | 52.46 | 0.70 | 11.09 | 5.81 | 0.10 | 3.55 | 22.20 | 1.05 | 2.60 | 0.42 | 111 | 379 | 181 | 90 | 45 | 439 | 130 | 349 | |

| 249/14 | handmade kitchen ware | 58.96 | 0.71 | 15.30 | 7.47 | 0.12 | 3.11 | 10.18 | 1.89 | 2.15 | 0.11 | 168 | 131 | 72 | 68 | 39 | 222 | 113 | 199 | |

| 250/14 | handmade kitchen ware | 58.42 | 0.78 | 17.77 | 9.43 | 0.15 | 4.55 | 4.73 | 1.99 | 2.06 | 0.13 | 221 | 251 | 104 | 77 | 54 | 172 | 114 | 222 | |

| 252/14 | handmade kitchen ware | 57.92 | 0.73 | 14.70 | 7.46 | 0.12 | 3.28 | 11.84 | 1.62 | 2.23 | 0.11 | 149 | 167 | 81 | 71 | 39 | 193 | 115 | 200 | |

| 253/14 | handmade kitchen ware | 46.04 | 0.87 | 13.44 | 8.87 | 0.12 | 4.22 | 22.80 | 1.27 | 2.10 | 0.26 | 178 | 238 | 114 | 94 | 37 | 279 | 134 | 162 | |

| 254/14 | handmade kitchen ware | 51.83 | 1.09 | 15.61 | 8.03 | 0.14 | 3.46 | 15.84 | 1.93 | 1.82 | 0.26 | 125 | 246 | 146 | 77 | 46 | 376 | 166 | 287 | |

| 255/14 | handmade kitchen ware | 55.34 | 0.74 | 17.89 | 10.40 | 0.17 | 6.07 | 5.72 | 2.12 | 1.37 | 0.19 | 263 | 172 | 76 | 80 | 43 | 232 | 80 | 191 | |

| mean | 51.85 | 0.72 | 13.54 | 7.07 | 0.11 | 4.56 | 17.96 | 1.51 | 2,46 | 0.21 | 142.80 | 282.18 | 152.92 | 80.55 | 45.76 | 376.91 | 117.25 | 285.91 | ||

| dev std | 5.26 | 0.17 | 2.95 | 1.98 | 0.03 | 1.24 | 8.79 | 0.41 | 0,72 | 0.09 | 61.23 | 121.89 | 68.73 | 9.65 | 8.54 | 166.36 | 22.91 | 107.78 | ||

| CV | 10.14 | 23.43 | 21.75 | 28.08 | 27.41 | 27.26 | 48.97 | 27.09 | 29,28 | 44.46 | 42.88 | 43.20 | 44.94 | 11.98 | 18.66 | 44.14 | 19.54 | 37.70 | ||

| skewness | 0.07 | 0.40 | 0.15 | 0.29 | 0.56 | 0.73 | -0.27 | 0.32 | 0,63 | 0.95 | 0.66 | 0.96 | 0.29 | 0.20 | 0.27 | 0.20 | 0.39 | 0.93 | ||

| kurtosis | -1.49 | 2.43 | -1.14 | -1.21 | -0.53 | -0.24 | -1.29 | -1.77 | 0,05 | 0.93 | 0.19 | 0.65 | -1.44 | -1.56 | -1.07 | -1.60 | 1.39 | 0.41 | ||

| variance | 2.57 | 3.20 | 3.42 | 4.03 | 3.85 | 3.15 | 8.12 | 3.95 | 3,28 | 4.31 | 6.58 | 4.33 | 4.96 | 2.18 | 2.49 | 4.93 | 2.60 | 3.80 | ||

| total variation | 1.99 |

The diachronic trend towards normality revealed by the skewness and kurtosis (Table 5 and Fig 9a–9c) is not as gradual as that towards homogeneity mentioned above: after the LC1-2 (Fig 9a), the LC3-4 marks a break distinguished by the most asymmetric and heavy-tailed distribution of data due especially to Fe2O3, MnO, P2O5, Zn and Ba concentrations (Fig 9b), followed by the final Late Chalcolithic phase (5) that shows the highest normality (Fig 9c).

Skewness and kurtosis calculated for each element within the LC1-2 (a), LC3-4 (b) and LC5 (c).

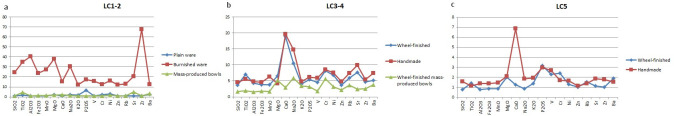

Within each Late Chalcolithic sub-phase, the variability indexes noticeably fluctuate according to the production rate and manufacturing techniques (Tables 6 and 7; Figs 10a–10c and 11a–11c). In the first Late Chalcolithic phase, when the whole production is still entirely handmade, the mass-produced bowls show slightly lower values of elemental CVs and variances as well as of total variation (Tables 6 and 7; Figs 10a and 11a), while the burnished ware exhibits the highest geochemical variability for all the considered parameters. In the following phases (Tables 6 and 7; Figs 10b, 10c, 11b and 11c), that part of the assemblage which is now shaped on the wheel is chemically more homogeneous than handmade vessels. The calculations on LC3-4 wheel-finished vessels also include mass-produced bowls; when extrapolated, mass-produced bowls show a wider gap with the rest of the wheel-finished vessels (difference in total variation = 1.67) than that separating these latter from handmade exemplars (difference in total variation = 0.5). Chemical CVs and total variations calculated separately (S1 Table; Tables 8 and 9) on each single ware of the LC3-4 period evidence further interesting trends. The handmade monochrome/red-burnished and kitchen wares stand out for their chemical variability, while a much more homogeneous composition occurs in the wheel-finished mass-produced bowls and chaff-tempered smoothed ware as well as in the handmade light-colored ware. Intermediate values were instead obtained for the wheel-finished red-slipped burnished, kitchen and light-colored fine wares. Thus, the LC3-4 chemical variability is affected not only by the forming techniques and production rates but also by the type of surface treatments, firing conditions and the calcareous content of the clay matrix. Chemically more heterogeneous are the vessels with a non-calcareous clay matrix, burnished and fired in reducing or mixed atmospheres, such as the monochrome/red-burnished and kitchen wares. By contrast, more homogeneous compositions occur in calcareous-rich, light-colored, smoothed or plain vessels including the mass-produced, chaff-tempered smoothed and light-colored wares. In contrast, functionality does not play a significant role on the chemical standardization, as the same vessel shape might show very different chemical indexes. As opposed to LC3-4, the few wares of the LC5 period do not differ that much from each other in terms of chemical variability.

Relationships between elemental CVs and ceramic wares/manufacturing techniques found in the LC1-2 (a), LC3-4 (b) and LC5(c).

Relationships between elemental variances and ceramic wares/manufacturing techniques found in the LC1-2 (a), LC3-4 (b) and LC5(c).

| Average CVs | LC1-2 | LC3-4 | LC5 | ||||

|---|---|---|---|---|---|---|---|

| Plain ware | Burnished ware | Mass-produced bowls | Handmade wares | Wheel-finished wares | Handmade wares | Wheel-finished wares | |

| SiO2 | 3.12 | 11.43 | 3.13 | 3.27 | 10.37 | 9.17 | 7.69 |

| TiO2 | 33.81 | 35.10 | 46.05 | 34.20 | 44.49 | 17.61 | 19.61 |

| Al2O3 | 0.79 | 37.36 | 10.80 | 15.01 | 19.98 | 11.09 | 8.93 |

| Fe2O3 | 16.10 | 55.48 | 18.53 | 35.58 | 18.80 | 13.63 | 10.61 |

| MnO | 4.28 | 95.25 | 15.98 | 33.35 | 15.37 | 16.31 | 10.06 |

| MgO | 16.39 | 108.92 | 13.63 | 11.53 | 29.86 | 26.92 | 27.95 |

| CaO | 11.58 | 87.33 | 14.70 | 43.92 | 30.72 | 56.85 | 16.77 |

| Na2O | 15.57 | 106.73 | 21.45 | 75.97 | 41.04 | 17.10 | 12.06 |

| K2O | 12.15 | 46.44 | 8.09 | 17.39 | 20.31 | 16.34 | 7.66 |

| P2O5 | 62.24 | 9.95 | 7.91 | 19.23 | 48.52 | 40.96 | 29.03 |

| V | 15.65 | 25.28 | 9.96 | 45.32 | 26.45 | 27.44 | 18.41 |

| Cr | 37.69 | 77.93 | 1.92 | 52.00 | 36.48 | 25.22 | 23.81 |

| Ni | 42.80 | 93.89 | 12.20 | 43.06 | 28.23 | 28.55 | 18.62 |

| Zn | 14.04 | 47.97 | 13.17 | 17.89 | 13.69 | 11.96 | 13.03 |

| Rb | 0.62 | 54.24 | 6.61 | 15.02 | 28.51 | 14.39 | 18.69 |

| Sr | 1.01 | 69.16 | 27.94 | 59.78 | 37.92 | 30.01 | 15.34 |

| Zr | 8.80 | 80.78 | 2.42 | 11.19 | 21.04 | 23.56 | 15.36 |

| Ba | 19.96 | 61.90 | 30.02 | 51.87 | 26.74 | 20.21 | 18.47 |

| Mean | 17.59 | 61.40 | 14.70 | 32.53 | 27.70 | 22.63 | 16.23 |

| Phase | Ceramic classes | Total variation | Elemental variance | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | V | Cr | Ni | Zn | Rb | Sr | Zr | Ba | |||

| LC1-2 | Plain ware | 0.92 | 1.25 | 1.96 | 1.08 | 0.98 | 0.98 | 2.22 | 0.92 | 2.14 | 1.84 | 6.64 | 0.97 | 2.35 | 2.97 | 0.94 | 1.09 | 1.15 | 0.92 | 2.59 |

| Mass-produced bowls | 0.88 | 0.88 | 4.69 | 0.95 | 1.34 | 1.32 | 1.98 | 2.20 | 1.46 | 0.88 | 1.09 | 0.93 | 0.93 | 1.81 | 0.89 | 0.88 | 4.89 | 0.91 | 3.48 | |

| Burnished ware | 12.08 | 24.64 | 34.74 | 40.44 | 23.86 | 27.28 | 37.97 | 15.28 | 30.52 | 12.07 | 17.30 | 15.63 | 12.52 | 16.18 | 12.07 | 13.00 | 20.74 | 67.69 | 12.81 | |

| LC3-4 | Wheel-finished | 3.19 | 3.72 | 7.11 | 4.26 | 3.88 | 3.79 | 6.53 | 18.85 | 10.58 | 4.09 | 5.45 | 4.56 | 8.15 | 6.78 | 3.68 | 5.89 | 7.72 | 4.73 | 5.22 |

| Mass-produced bowls | 1.52 | 1.65 | 1.95 | 1.58 | 1.77 | 1.75 | 5.20 | 2.99 | 5.93 | 3.47 | 3.15 | 1.87 | 5.66 | 3.15 | 2.18 | 3.71 | 2.42 | 2.59 | 3.82 | |

| Handmade | 3.68 | 4.53 | 5.57 | 4.76 | 4.61 | 6.27 | 4.22 | 19.59 | 14.84 | 4.87 | 6.15 | 5.90 | 8.57 | 7.53 | 4.83 | 7.37 | 9.95 | 5.41 | 7.40 | |

| LC5 | Wheel-finished | 0.73 | 0.80 | 1.44 | 0.80 | 0.85 | 0.87 | 2.01 | 1.26 | 0.87 | 1.37 | 3.19 | 2.31 | 2.43 | 1.32 | 1.00 | 1.53 | 1.14 | 1.04 | 1.91 |

| Handmade | 1.01 | 1.57 | 1.14 | 1.40 | 1.37 | 1.47 | 2.08 | 6.89 | 1.87 | 1.95 | 2.96 | 2.68 | 1.70 | 1.66 | 1.16 | 1.37 | 1.86 | 1.76 | 1.56 | |

| Average CVs | LC3-4 ceramic wares | LC5 ceramic wares | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Handmade | Wheel-finished | Handmade | Wheel-Finished | ||||||||

| Light-colored | Red-black/ monochrome burnished | Kitchen | Kitchen | Fine light-colored | Red-slipped burnished | Chaff-tempered smoothed | Mass-produced | Kitchen | Light-colored semifine | Light-colored fine | |

| SiO2 | 1.24 | 0.12 | 11.59 | 5.22 | 11.91 | 14.56 | 10.80 | 14.53 | 9.17 | 9.50 | 5.88 |

| TiO2 | 51.42 | 23.06 | 39.24 | 67.90 | 39.80 | 49.99 | 22.54 | 18.85 | 17.61 | 11.53 | 27.70 |

| Al2O3 | 12.32 | 12.09 | 23.54 | 14.39 | 29.43 | 28.18 | 13.30 | 20.18 | 11.09 | 3.58 | 14.28 |

| Fe2O3 | 18.07 | 41.16 | 41.91 | 22.07 | 28.70 | 23.02 | 9.42 | 7.50 | 13.63 | 9.19 | 12.03 |

| MnO | 10.16 | 33.89 | 55.47 | 13.08 | 24.42 | 24.41 | 9.73 | 7.49 | 16.31 | 10.74 | 9.38 |

| MgO | 3.96 | 8.68 | 24.81 | 23.51 | 22.91 | 33.37 | 29.18 | 46.67 | 26.92 | 30.69 | 25.20 |

| CaO | 28.25 | 13.83 | 119.75 | 8.68 | 51.35 | 40.59 | 55.02 | 20.00 | 56.85 | 16.83 | 16.72 |

| Na2O | 53.03 | 88.22 | 74.42 | 39.07 | 57.51 | 37.80 | 21.38 | 51.41 | 17.10 | 16.38 | 7.75 |

| K2O | 10.68 | 13.09 | 32.72 | 24.42 | 10.98 | 17.38 | 12.45 | 32.23 | 16.34 | 3.16 | 12.16 |

| P2O5 | 18.80 | 7.70 | 42.73 | 61.25 | 31.91 | 67.75 | 36.90 | 32.06 | 40.96 | 28.78 | 29.29 |

| V | 20.94 | 55.71 | 48.93 | 31.95 | 24.54 | 34.77 | 24.74 | 10.77 | 27.44 | 2.27 | 34.55 |

| Cr | 29.86 | 50.51 | 77.12 | 40.65 | 35.82 | 30.42 | 30.17 | 41.16 | 25.22 | 6.07 | 41.56 |

| Ni | 24.82 | 42.63 | 62.16 | 28.92 | 28.18 | 21.96 | 37.25 | 24.14 | 28.55 | 21.85 | 15.40 |

| Zn | 3.70 | 15.06 | 37.74 | 11.74 | 9.09 | 16.78 | 13.50 | 19.30 | 11.96 | 11.24 | 14.82 |

| Rb | 3.09 | 3.11 | 50.76 | 14.94 | 30.55 | 47.44 | 24.01 | 39.17 | 14.39 | 8.07 | 29.30 |

| Sr | 6.90 | 95.10 | 42.03 | 45.92 | 54.97 | 33.30 | 24.78 | 22.60 | 30.01 | 26.35 | 4.33 |

| Zr | 11.36 | 0.27 | 32.86 | 24.60 | 10.36 | 26.68 | 13.93 | 26.05 | 23.56 | 12.61 | 18.11 |

| Ba | 25.09 | 76.12 | 30.15 | 16.69 | 36.85 | 41.78 | 16.40 | 32.05 | 20.21 | 15.90 | 21.04 |

| Mean | 18.54 | 32.24 | 47.11 | 27.50 | 29.96 | 32.79 | 22.53 | 25.90 | 22.63 | 13.60 | 18.86 |

| Phase | Ceramic wares | Total variation | Elemental variance | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | V | Cr | Ni | Zn | Rb | Sr | Zr | Ba | ||||

| LC3-4 | Wheel-finished | Kitchen | 1.94 | 2.22 | 8.01 | 2.22 | 2.48 | 2.19 | 3.31 | 2.25 | 4.79 | 3.50 | 8.66 | 3.94 | 5.49 | 4.26 | 2.00 | 2.81 | 6.49 | 2.47 | 2.60 |

| Mass-produced bowls | 1.52 | 1.65 | 1.95 | 1.58 | 1.77 | 1.75 | 5.20 | 2.99 | 5.93 | 3.47 | 3.15 | 1.87 | 5.66 | 3.15 | 2.18 | 3.71 | 2.42 | 2.59 | 3.82 | ||

| Fine light-colored | 2.56 | 2.80 | 5.40 | 3.98 | 3.71 | 3.48 | 3.40 | 12.37 | 8.90 | 2.85 | 4.32 | 3.50 | 5.18 | 4.16 | 2.65 | 4.58 | 13.20 | 2.84 | 4.70 | ||

| Red-slipped burnished | 3.01 | 3.37 | 6.25 | 3.94 | 3.63 | 3.88 | 6.20 | 24.84 | 4.93 | 3.70 | 5.96 | 4.48 | 5.20 | 4.52 | 3.56 | 5.87 | 8.91 | 3.85 | 5.33 | ||

| Chaff-tempered smoothed | 1.26 | 2.07 | 1.98 | 2.23 | 1.45 | 1.44 | 1.96 | 9.25 | 2.92 | 1.58 | 2.45 | 1.74 | 2.19 | 2.99 | 1.28 | 3.38 | 1.82 | 2.19 | 2.54 | ||

| Handmade | Light-colored | 1.06 | 1.06 | 5.71 | 1.21 | 1.47 | 1.15 | 1.15 | 2.86 | 6.06 | 1.40 | 1.93 | 1.64 | 3.06 | 2.48 | 1.06 | 1.06 | 1.08 | 1.18 | 2.51 | |

| Red-black/monochrome burnished | 4.26 | 4.38 | 4.66 | 5.01 | 6.35 | 5.50 | 4.26 | 4.31 | 26.73 | 4.30 | 4.72 | 8.86 | 7.82 | 6.55 | 4.34 | 4.49 | 31.77 | 4.39 | 14.86 | ||

| Kitchen | 4.97 | 5.85 | 7.19 | 7.26 | 6.45 | 9.83 | 5.36 | 29.35 | 21.13 | 6.94 | 6.94 | 7.50 | 11.31 | 10.96 | 7.11 | 11.72 | 9.35 | 8.52 | 6.05 | ||

| LC5 | Wheel-finished | Light-colored semifine | 0.47 | 0.65 | 0.73 | 0.50 | 0.64 | 0.69 | 2.17 | 0.95 | 0.93 | 0.49 | 2.05 | 0.48 | 0.52 | 1.30 | 0.71 | 0.57 | 1.70 | 0.78 | 0.95 |

| Light-colored fine | 0.81 | 0.86 | 1.99 | 1.07 | 0.91 | 0.90 | 2.18 | 1.61 | 0.86 | 0.90 | 1.66 | 3.12 | 4.10 | 1.50 | 1.22 | 2.32 | 1.00 | 1.24 | 1.80 | ||

| Handmade | Kitchen | 1.01 | 1.57 | 1.14 | 1.41 | 1.35 | 1.47 | 2.11 | 6.89 | 1.87 | 1.95 | 2.96 | 2.68 | 1.70 | 1.66 | 1.16 | 1.37 | 1.86 | 1.74 | 1.56 | |

Independently of periods and wares, elemental CVs and variances are respectively higher for CaO, Na2O, Cr, V, Ni, P2O5, Sr, Ba and CaO, Na2O, Sr (Table 5; Figs 7 and 8). Based on the skewness and kurtosis the V, Cr, Zn and Rb concentrations diverge most extensively from a normal distribution (Table 5; Fig 9a–9c). Although some of these more variable elements are known to be sensitive to post-depositional processes (e.g. CaO, P2O5), most of them are instead related to distinct local strategies in raw material procurement and paste preparation. Indeed, previous studies have already demonstrated that the geochemical variation in the ceramics from Arslantepe is mostly linked to the exploitation of more and less calcareous clay deposits tempered with materials characterized by different mafic/felsic/alkaline affinities [85]. Calcareous and non-calcareous deposits are respectively available in the plain and in the southern Anti-Taurus Mountains. Clay pastes tempered with acid rocks (e.g. petro-groups CEm-a and VCEm-a) are richer in Ba, Rb, K2O, SiO2 and poorer in TiO2, Fe2O3, V, MnO, MgO, Cr and Ni. Opposite geochemical trends characterize the samples containing minerals and rocks of mafic origin (petro-groups CEb-m, CIb, VCIb, VIb, VMetag). In particular, metagabbroic pastes (petro-group VMetag) are strongly enriched in V, related to ultramafic rocks of ophiolite-related petrogenesis. Ceramic pastes with intermediate rocks (e.g. VCEm, VEm) show intermediate features between the terms mentioned above, but they are distinguished by high Al2O3, K2O, Na2O and Sr values.

Petro-chemical discrepancies in diachronic trends towards standardization

The various indexes and forms applied to explore the petrographic variability of Late Chalcolithic vessel from Arslantepe (Table 10) evidence different trends than those obtained through the elaboration of geochemical data: at a petrographic level it is the LC3-4 and not the final LC5 that shows the lowest variability. Indeed, the lowest richness, evenness and disparity unequivocally characterize the LC3-4 phase, as the various diversity indexes provide the lowest values; petro-loners occur more rarely; samples are unevenly apportioned into petro-groups; and the average number of samples per petro-group is higher.

| RICHNESS | EVENNESS | RICHNESS+EVENNESS | DISPARITY | ||||

|---|---|---|---|---|---|---|---|

| % petro-loners | Menhinick’s | Disparity in recipe abundance | Average nr of samples per petro-group | Pielou’s | Shannon’s | Jaccard’s dissimilarity % | |

| LC1-2 | 57.89 | 3.21 | 16 | 2.67 | 0.95 | 2.51 | 88.89 |

| LC3-4 | 15.46 | 2.44 | 18 | 9.11 | 0.79 | 2.51 | 66.38 |

| LC5 | 31.37 | 3.64 | 12 | 3.5 | 0.92 | 3 | 66.48 |