Competing Interests: The authors have declared that no competing interests exist.

‡ These authors also contributed equally to this work.

- Altmetric

Various items of roll molds are popularly used to fabricate different kinds of optical films for optoelectronic information and other new and high-tech fields, while the fabrication and evaluation of optical microstructures on a cylindrical roller surface is more difficult than ecumenically manufactured products. In this study, the machinability of microstructures on the roll based on a fast tool servo (FTS) system is investigated. First, the flexible hinge holder for a FTS is designed and its structural parameters are optimized with finite-element analysis and fatigue reliability theory. The tool radius compensation algorithm for complicated microstructures is then deduced based on the surface fitting and bilinear interpolation algorithm of discrete data. Meanwhile, the evaluation index and method are proposed by the medium section method. Finally, a machining test of aspheric arrays on a cylindrical aluminum surface is carried out, and the high quality of the microstructure indicates that the proposed method is able to be used to fabricate optical microstructures.

Introduction

Optical films with various kinds of microstructures are extensively used in optical instruments, LED lighting, liquid-crystal display, and other applications [1–3]. The microstructure molding of optical films is reliant on the roller [2, 3], the surface of which is graduated in various microstructures. The patterns of optical film microstructures become increasingly complicated with their wide application, while the requirements of shape precision and surface roughness become higher [4]. Therefore, the machining technology of microstructures on roller surfaces is a key research direction in the fabrication of optical films [5].

The mainstream machining technology of microstructures is ultra-precision turning combined with the fast tool servo (FTS) supported by a piezo actuator, which has advantages of high peak acceleration and bandwidth [6, 7]. The United States and Germany are leaders in the relevant fields. For example, the various skills of DRL-type roll lathes of PRECITECH and TDM-series roll lathes of KUGLER are full-blown, and are those roll lathes are highly commercialized. Based on the DRL 1430 roll lathe and FTS 70, workers at Cranfield University (UK) manufactured a series sinusoidal grids with high precision [8]. Workers at the National University of Defense Technology (China) carried out significant work in the fabrication of microstructures on the end face with a home-grown FTS system, e.g., utilizing sinusoidal radiation, a sinusoidal phase plane, and a micro-lens array, in which the surface roughness of the lens array with circumferential arrangement reaches 11.4 nm [9].

Lu et al. designed a FTS system for precision machining and investigated the influence of the clearance angle of a diamond tool on the microstructure’s shape precision [10]. Based on the modification of the tool path, Yu et al. put forward a compensation method to pre-compensate the induced profile errors in FTS diamond turning, and effectively improved the machining precision of microstructures [11]. To predict the microstructure generation, Lu et al. proposed a method for calculating the microstructure profile amplitude and wavelength, and conducted a cutting test to validate the presented method [12]. Zhu et al. studied the feasibility of a novel quasi-elliptical tool servo for vibration suppression in the turning of micro-lens arrays, and effectively decreased the tool vibration caused by the motion non-smoothness in the FTS [13]. With the use of an error-correcting algorithm, Wang et al. performed a lens arrays with a 0.06-μm peak-to-valley value using the FTS system [14].

There is no uniform standard for the evaluation of microstructure surfaces at present due their complexity and particularity. The evaluation of surface quality for a single microstructure is generally shape error and surface roughness [15]. Zhou et al. developed some methods, such as pattern and characteristic parameter analysis methods, evaluation methods based on inherent characteristics of curved surfaces, and a template matching method, to measure and evaluate microstructure surfaces [16]. A series of evaluation parameters were determined in which the evaluation of microstructure surfaces from single to whole was implemented, aiding the error diagnosis and process optimization [16, 17].

The machining equipment, processing techniques, error compensation methods, and precision evaluation for microstructures were deeply discussed in the above-mentioned studies. While the complexity of the microstructure pattern makes the fabrication and evaluation of the microstructures on a roller surface more difficult, the reliability of the design on FTS must be strengthened. In response, in this study, a tool radius compensation algorithm and an evaluation method for complicated microstructures are proposed, and a machining experiment of aspheric arrays on a cylindrical aluminum surface based on a designed FTS with the consideration of fatigue reliability performed.

Identification of FTS system

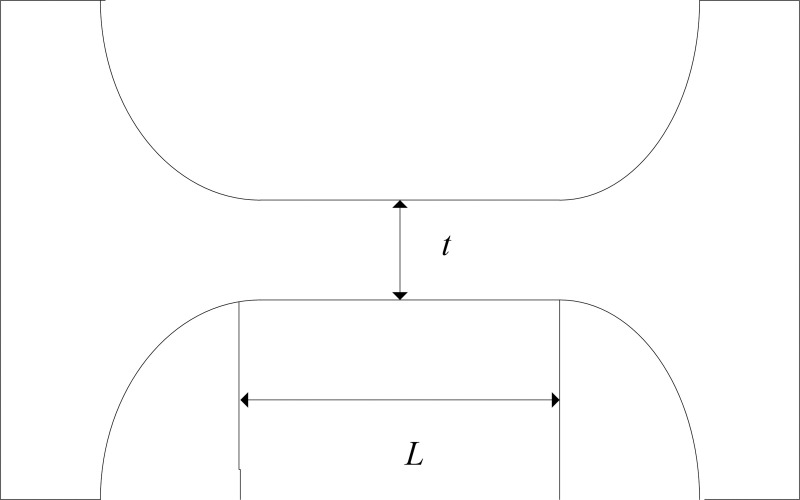

A FTS system is generally driven by a piezoelectric actuator and its motion transferred by a flexible hinge holder; the hinge usually adopts the straight beam structure according to the performance requirements of the system [18]. Fig 1 is a diagram of a straight beam hinge.

Diagram of hinge with straight beam structure.

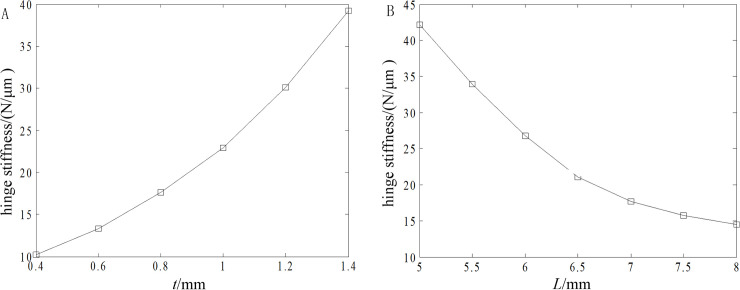

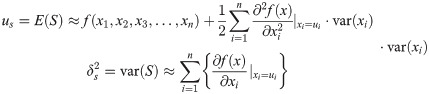

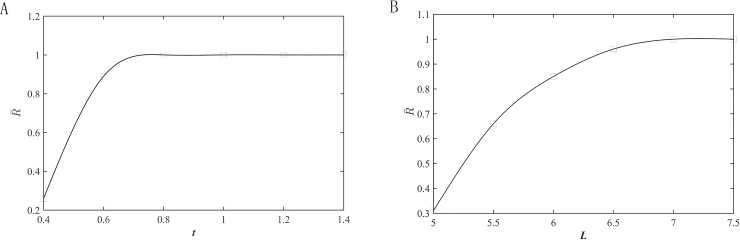

Taking the minimal thickness t and beam length L that most affect the behaviors as design factors. With the restrains on the positions of hinge bolt holes and the load on the part in contact with piezoelectric ceramics, the influences of t and L on the hinge stiffness are shown in Fig 2 based on an ANSYS simulation, in which the other structure parameters are in accord with those in Ref. [18]. It can be seen from the figure that the stiffness increases with minimal thickness t and decreases with beam length L.

Influences of minimal thickness t and beam length L on hinge stiffness.

(A) Minimal thickness and (B) Beam length.

The FTS system makes high-frequency reciprocating motions under working conditions, and the alternating stress on it tends to lead to fatigue failure, which means that the design method for a FTS based on static strength is likely to lead to pre-mature fatigue failure or overdesign of the system [19].

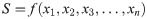

Supposing that f(S) and f(σ) are the probability density functions of stress S and strength σ, respectively, the fatigue reliability can be obtained by

Where S and σ are functions of random variables, such as material property, dimension, and environment variable, and the determinations of their probability density functions must synthesize the distributions of related parameters into comprehensive distributions. Based on the moment method, S can be expressed by

Where xi (i = n) are the design variables.

The moment method supposes that S observes the normal distribution,

Where E(S) and var(S) are the first-order origin moment and second-order central moment about S, respectively.

With the combination of Eqs (1) and (3), the fatigue reliability

Influences of minimal thickness t and beam length L on fatigue reliability

(A) Minimal thickness and (B) Beam length.

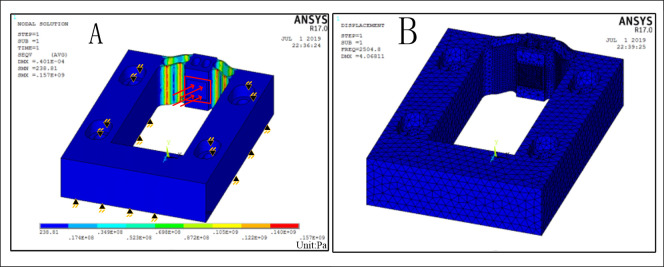

According to the results in Figs 2 and 3, the values of t and L are 0.8 and 7 mm, respectively. Fig 4 presents the stress distribution with a 40-μm displacement and the first-order mode shapes of the optimized hinge, and the results are far less than their corresponding critical values. The hinge is obtained by milling and wire cutting.

Simulations of stress distribution and first natural frequency.

(A) Stress distribution and (B) First natural frequency.

Compensation of tool radius

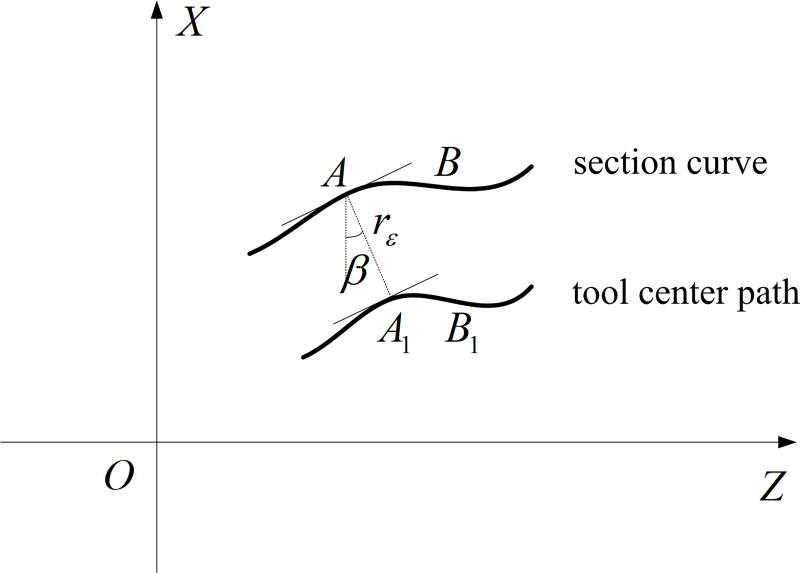

In the process of ultra-precision machining for arbitrary surfaces, the programming path is the tool center path. The arc radius of the diamond tool tip is rε, and the microstructure contour curve is the envelope at a distance rε from the central trajectory of the diamond tool. To obtain the microstructure contour, it is necessary to compensate the tool radius, except for the pyramid microstructure machined by a sharp tool [20].

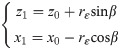

The microstructure on a cylindrical surface is expressed by x = g(z, θ), where z and θ are the height of the microstructure on the cylinder and the angle of the microstructure in the circumferential direction. The central trajectory of the diamond tool after tool radius compensation can be obtained according to Fig 5.

Section curve and tool center path at angle θ.

The curve of microstructure surface on a certain section is the section curve and when the tool moves on the section curve, the path of the tool radius is the tool center path. Supposing that AB and A1B1 are the section curve and tool center path, respectively, and that the spacing between them is rε, the slope of any point A(z0, x0) on AB at θ is

Where ß is the slope angle.

The related point A1(z1, x1) on A1B1 can be obtained by

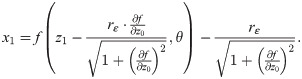

According to Eqs (4) and (5), the equation of the tool center path at θ after tool radius compensation is

For more complicated microstructure surfaces such as sinusoidal grids and aspherics, the obtainment of the related tool center paths by Eq (6) is complicated. With the calculation for the tool points carried out according to surface discrete points, the related data of the depth of cut can be generated, and the values of the depth of cut near the data points should be obtained by interpolation calculation.

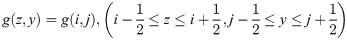

The common mean of interpolation calculation is a nearest-neighbor algorithm, i.e.,

Where g(i, j) and g(z, y) are the known data points and interpolation results, respectively.

Although the nearest-neighbor algorithm has a small amount of calculation and fast calculation speed, the calculation precision is not high. The bilinear interpolation algorithm is able to effectively improve the calculation precision, and its core idea is the linear interpolations in two directions.

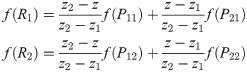

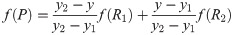

As shown in Fig 6, P11, P21, P12, and P22 are the four known points on the surface, and P(z, y) is any point inside the four points. The linear interpolation in Z direction is

Where R1 = (z,y1), R2 = (z,y2), f(P11), f(P21), f(P12), f(P22), f(R1), and f(R2) are the values of the depth of cut of the six points. Next, the linear interpolation in the Y direction is

Where f(P) is the value of the depth of cut of point P.

Schematic diagram of bilinear interpolation algorithm.

Based on the least-squares method, the depth-of-cut values of the discrete point are fitted to a surface equation, which can be used for tool radius compensation.

The fabrication of microstructures on cylindrical surface is restricted by the tool geometry, FTS characteristic, and process parameters, which influences the precision and quality of the finished surface. Study of the restriction rule of the manufacturability of such objects is able to determine the selection of tools and process parameters.

Precision evaluation of microstructure arrays

The machining accuracy is fundamentally determined by the position relationship between workpiece and cutter in the process of machining, and is also closely related to the size of various parameters during processing. For a long time, there has not been a reasonable and unified evaluation standard for cylindrical or roller surface microstructure arrays. Because the array of micro structures is distributed on the cylinder surface, it is very difficult to detect.

The form Talysurf 1240 profilometer is used to measure the maximum profile of the microstructure along the axis of the workpiece, and the surface quality of the microstructure is indirectly evaluated from the roughness and profile deviation of the contour line. Roughness is the high frequency component of contour, which is obtained by high pass filtering method, and the root mean square deviation (RMS) is used to calculate the roughness.

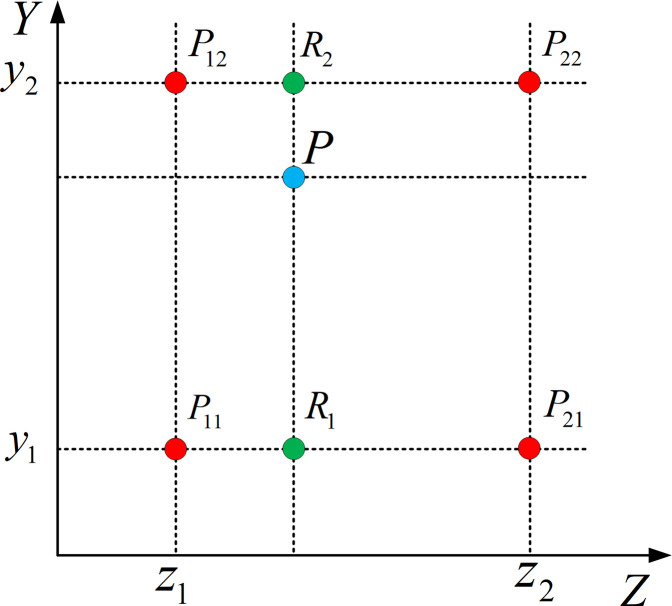

The root-mean-square deviation Sq and contour deviation ST of the isocline are adopted to evaluate the precision of microstructures on cylindrical surface. Sq and ST are high- and low-frequency components, respectively, and their formulas are

Where N is the number of sampling points; xh(zi) and xl(zi) are the contour data points after high- and low-pass filtering, respectively; x(zi) are ideal contour data; i = 1,2,…,N.

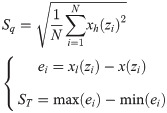

The ideal and measured contour curves should be matched because their coordinate systems are different. As shown in Fig 7, XOZ and X’O’Z’ are the coordinate systems of ideal and measured contours, respectively; n and n’ are the normal vectors of ideal and measured contours, respectively; A,C and A’,C’ are the endpoints of the ideal and measured contours; B’ are the lowest points of ideal and measured contours, respectively; B and B’ are the lowest points of ideal and measured contours, respectively.

Coordinate systems of ideal and measured contours.

Anti-tilting of the measured contour curves is used to make the normal vectors of the two curves in the same direction. The spacing between the endpoints and lowest point of each contour based on the three-point fix method is regarded as the objective function, and the translation vector M is obtained by minimum calculation. The measured contour can be effectively and quickly matched with the ideal contour by the following equation:

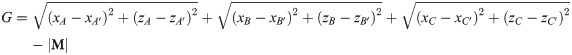

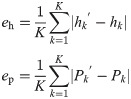

The overall evaluation for microstructure arrays can be determined by the overall depth error eh and pitch error ep. Their calculation formulas are

Where hk and Pk are the ideal kth maximal depth of cut and pitch along the axial direction of microstructure arrays, respectively; hk’ and Pk’ are the actual kth maximal depth of cut and pitch along the axial direction of microstructure arrays, respectively; k = 1,2,…,K. It is worthy of note that the pitch Pk is the spacing between any line parallel to the axial direction of microstructure arrays and the intersection at the same position on the measured contour curve.

Processing and evaluation of microstructure arrays of aspheric arrays

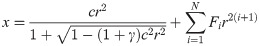

Owing to their high optical quality, aspheric surface optical parts are widely used in modern photoelectric products. The general mathematical formula for aspherics is

Where c = 1/R, and R is the base circle radius of curve; γ is the conic coefficient; Fi are aspheric coefficients.

Based on the NF350-type ultra-precision lathe and designed FTS system, a processing test of aspheric microstructure arrays on a cylindrical aluminum workpiece with a diameter of 50 mm and height of 20 mm was carried out. The values of c, γ, and Fi were set as 1, 0, and 1/2000, respectively, and other parameters are as shown in Table 1.

| Spindle speed (r·min−1) | Cut of depth of optical surface (μm) | Feed speed for optical surface (mm·min−1) | Feed speed for arrays (mm·min−1) | Length of arrays (mm) | Depth of aspherics (μm) | Arc radius of diamond tool tip rε (mm) |

|---|---|---|---|---|---|---|

| 15 | 10 | 0.4 | 0.4 | 8 | 15.749 | 1 |

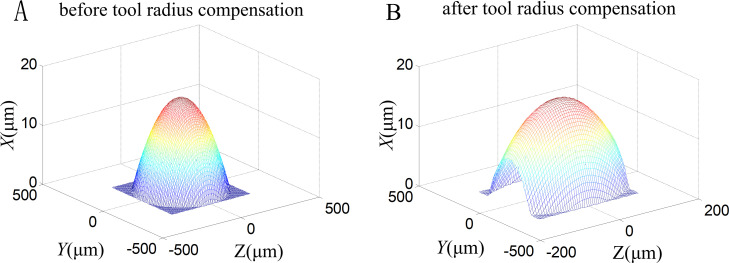

According to Eq (6), the tool radius compensation for aspherics is difficult. The aspheric surface is discretized and the tool center position related to each discrete point is calculated, and then the data are converted into grids based on a bilinear interpolation algorithm. Fig 8 shows the simulation images of the aspheric surface before and after tool radius compensation.

Simulation images of aspheric surface before and after tool radius compensation.

(A) Before and (B) After tool radius compensation.

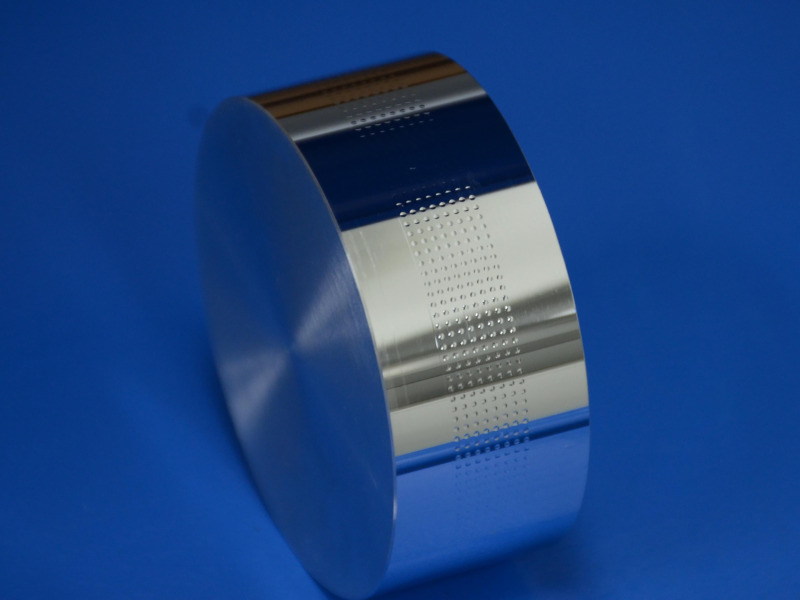

The aspheric microstructure arrays on cylindrical surface are processed successfully with the techniques and equipment described above, and the processing result is shown in Fig 9.

Processing result of aspheric microstructure arrays on cylindrical surface.

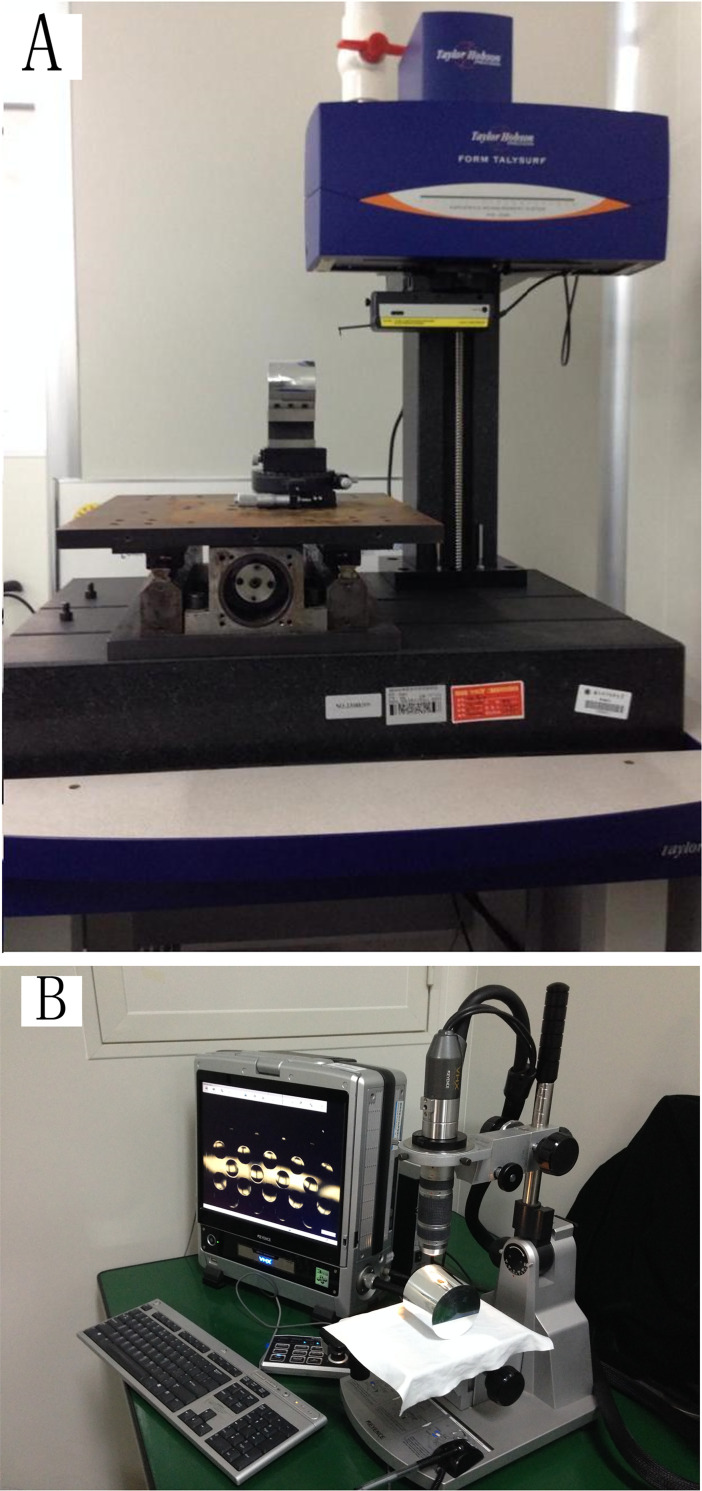

Owing to the large height difference and the difficulty of measurement along a circumferential direction, it is difficult for white-light and wavefront interferometers to accurately measure the surface quality of aspheric microstructures on cylindrical surfaces. A Talysurf PGI 1240-type profilometer and VH-Z5002-type microscope were used to examine contour deviation ST and root-mean-square deviation Sq, respectively. Fig 10 shows the measurement scene.

Measurement scene.

(A) Profilometer and (B) Microscope.

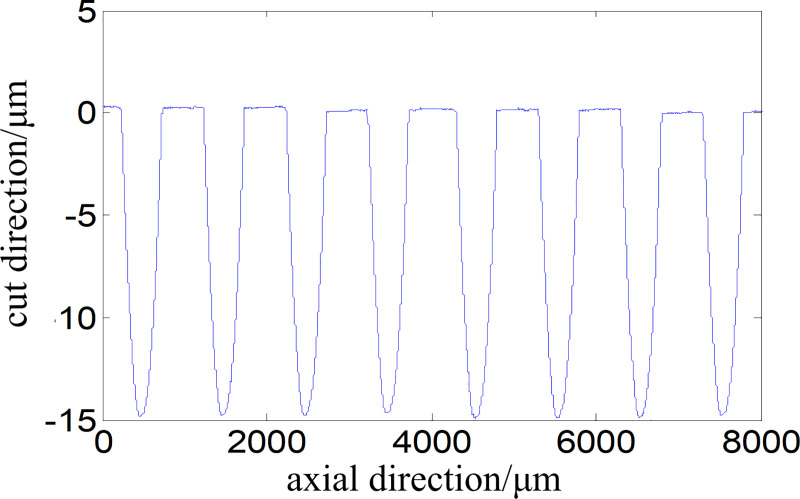

The contours of the aspheric arrays along the axial direction are shown in Fig 11. After measured data analysis, it is known that the values of overall depth error eh and pitch error ep are 1.034 and 1.943μm, respectively, and the values of root-mean-square deviation Sq and contour deviation ST are 0.022 and 0.51 μm, respectively. The results indicate that the proposed FTS system and method are able to effectively process and evaluate the complicated microstructures on cylindrical surfaces.

Contours of studied aspheric arrays.

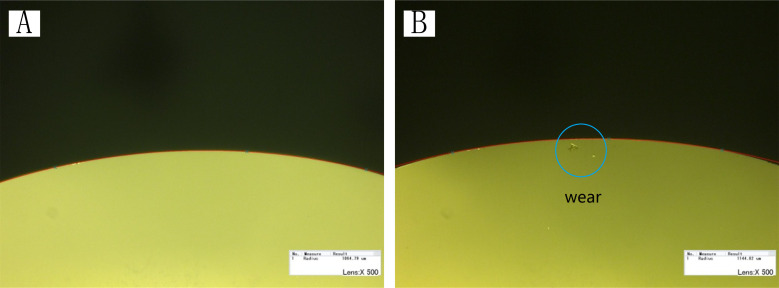

Fig 12 shows the microscopic observations of the diamond tool before and after processing. There is no damage on the circular tool, while the arc radius rε increases and the increment is 80.03 μm, which indicates that the tool is slightly worn during the working process. The machining of microstructures with the FTS system is a high-frequency motion, and a high-quality tool is necessary.

Microscopic observations of diamond tool (A) before (rε = 1064.79 μm) and (B) after processing (rε = 1144.82 μm).

Conclusions

The process and evaluation of complicated microstructures on cylindrical surface are investigated, and verification tests carried out based on the designed FTS system and an ultra-precision lathe. The following conclusions are drawn from the results.

With the consideration of fatigue reliability, the structure parameters of the straight beam hinge is optimized by ANSYS simulation to obtain high performance of the FTS system.

The tool radius compensation for the machining of complicated microstructures is performed based on data discretization and a bilinear interpolation algorithm.

Root-mean-square deviation Sq, contour deviation ST, overall depth error eh, and pitch error ep are proposed as evaluation indexes.

The process of fabricating aspheric microstructure arrays on cylindrical surfaces indicates the feasibility and reliability of the proposed FTS system and method, which is useful for the fabrication of optical films.

Acknowledgements

We thank LetPub (www.letpub.com) for its linguistic assistance during the preparation of this manuscript.

References

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Fabrication and evaluation of complicated microstructures on cylindrical surface

Fabrication and evaluation of complicated microstructures on cylindrical surface