Introduction

Our understanding of crystal growth is built on a powerful paradigm quantified by Burton, Cabrera, and Frank (BCF)–, in which atoms are added to the growing crystal surface by attachment at the steps forming the edges of each exposed atomic layer, or terrace. The BCF model was originally developed for crystals with step heights of a full unit-cell and step properties that are identical from step to step for a given step direction. However, from the beginning it was recognized that there could be more complex situations. When the space group of the crystal includes screw axes or glide planes, the growth behavior can be fundamentally different on facets perpendicular to one of these symmetry elements. In this case, the terraces can still all have the same atomic arrangement, but now have different in-plane orientations of their top layer. The fractional-unit-cell-height steps that separate these terraces have structures and properties that can vary from step to step, even for a fixed step direction. Thus, surface morphologies with alternating terrace widths can arise that depend upon the deposition or evaporation conditions, as indicated in Fig. 1. The inequivalent kinetics at steps affects not only surface morphology but also the incorporation of alloying elements during crystal growth,.

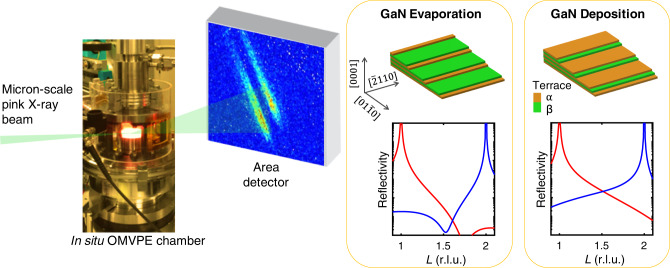

Fig. 1

Schematic of microbeam surface X-ray scattering during organo-metallic vapor phase epitaxy (OMVPE) growth.

Crystal truncation rod (CTR) measurements are sensitive to the α or β terrace fraction changes that occur on vicinal {0001} surfaces of HCP-type crystals during deposition or evaporation. Calculated reflectivities are shown for the CTRs from the and (011¯2) Bragg peaks (red and blue curves, respectively) with α terrace fractions fα = 0.1 and 0.9 typical for evaporation and deposition of GaN by OMVPE, as will be shown below.

A ubiquitous but subtle version of this effect occurs on the basal-plane {0001}-type surfaces of crystals having hexagonal close-packed (HCP) or related structures, which are normal to a 63 screw axis. Such crystals are made up of closely packed layers with 3-fold symmetry that alternate between opposite orientations, as shown by the α and β terrace structures in Fig. 2c. On a vicinal surface, the αβαβ stacking sequence typically results in half-unit-cell-height steps. The lowest energy steps are normal to ⟨011¯0⟩-type directions, and have alternating structures conventionally labeled A and B, as shown in Fig. 2a, b. When the in-plane azimuth of a step changes by 60°, for example, from [011¯0] to [101¯0], its structure changes from A to B or B to A.

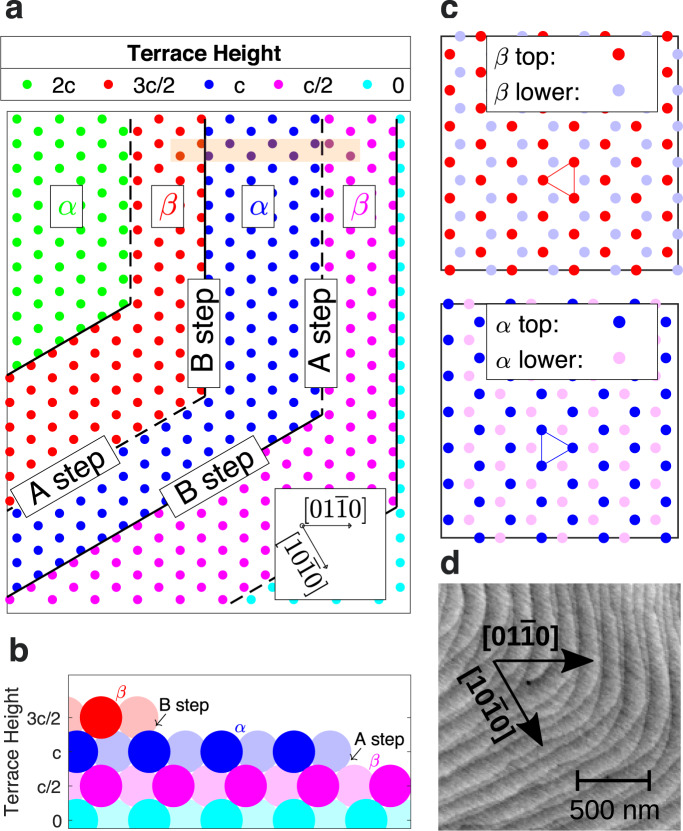

Fig. 2

Terrace and step structure of vicinal (0001) surface of an HCP-type crystal.

For GaN, only Ga atoms are shown. a Circles show top-layer sites on each terrace, with color indicating height. Steps typically have lowest edge energy when they are normal to [011¯0], [101¯0], or [11¯00]. Steps in a sequence have alternating structures, A and B, which swap when step azimuth changes by 60°. b Cross-section of the A and B step structures in the region marked by an orange rectangle in a. Lighter and darker colors indicate atoms in different rows. c Detail of α and β terrace structures. Orientation of triangle of top-layer atoms around 63 screw axis shows difference between layers. d AFM height image of GaN (0001) surface typical of films grown on sapphire substrates by OMVPE, showing regions of alternating step spacings and interlacing at corners where the step azimuth changes. Step heights are c/2 = 2.6 Å.

The alternating nature of the steps on such surfaces has been imaged in several systems, including SiC, GaN,,–, AlN, and ZnO. These systems typically show a tendency for local pairing of steps (i.e., alternating step spacings), and an interlaced structure in which the step pairs switch partners at corners where their azimuth changes by 60°, as shown in Fig. 2d. These features are consistent with predictions that A and B steps have significantly different attachment kinetics,,,– that lead to unequal local fractions of α and β terraces during growth. However, it has not been possible to experimentally distinguish the terrace orientation or step structure, and thus to determine whether A or B steps have faster kinetics.

In particular, the properties of A and B steps on GaN (0001) surfaces have been a matter of some disagreement. A seminal study of molecular beam epitaxy (MBE) of GaN observed alternating step shapes and proposed that the kinetic coefficients for adatom attachment are higher for A steps than B steps, that is, A steps grow faster for a given supersaturation. The support for this highly cited prediction is based on an argument regarding the difference in dangling bonds between A and B steps, and a comparison with experimental results on GaAs (111),. (Such face-centered cubic materials have A- and B-type steps that do not alternate between successive terraces and thus can be distinguished by their orientation.) In contrast, several subsequent theoretical studies of GaN (0001) organo-metallic vapor phase epitaxy (OMVPE) and MBE have consistently predicted that A steps have smaller adatom attachment coefficients than B steps. Kinetic Monte Carlo (KMC) studies of GaN (0001) growth under OMVPE conditions found step pairing driven by faster kinetics at B steps than A steps. The standard bond-counting energetics used in a KMC study of growth on an HCP lattice result in a much lower Ehrlich–Schwoebel (ES) barrier at B steps than at A steps, when only nearest-neighbor jumps are allowed. A recent KMC study of GaN (0001) growth under MBE conditions found triangular islands that close analysis reveals are bounded by A steps, indicating faster growth of B steps. An analysis of InGaN (0001) growth by MBE concluded that adatom attachment at B steps is faster, converting them into crenelated edges terminated by A steps.

The difference between the kinetics at A and B steps is a reflection of the chemical states of the adatoms, steps, and terraces that affect the dynamics of A and B steps. Studies of islands on the FCC Pt (111) surface, have found that A steps have a higher growth rate than B steps, but that this relationship is reversed by the presence of adsorbates such as CO. An experimental study of AlN (0001) surfaces grown by OMVPE found a change in the terrace fraction as a function of the V/III ratio used during growth. Ab initio calculations of kinetic barriers on GaN and AlN (0001) under MBE and OMVPE conditions– found that the barriers and adsorption energies at A and B steps depend in detail on the surface reconstruction induced by the environment. Thus, to properly understand, model, and control (0001) surface morphology in HCP-type systems, there is a need for an in situ experimental method that can distinguish adatom attachment kinetics at A and B steps in the relevant growth environment.

Here, we show that in situ surface X-ray scattering can distinguish the fraction of the surface covered by α or β terraces during growth, unambiguously determining differences in the attachment kinetics at A and B steps. X-rays are an ideal probe since they are sensitive to atomic-scale structure and can penetrate the growth environment. This method is enabled by using a micron-scale X-ray beam that illuminates a surface region of a high-quality single crystal having a uniform step azimuth, as shown in Fig. 1. We demonstrate this for OMVPE of (0001) GaN, with measurements of crystal truncation rods (CTRs) carried out in situ during growth. CTRs are streaks of intensity extending in reciprocal space away from every Bragg peak in the direction normal to the crystal surface, which are sensitive to the surface structure. We fit calculated CTRs from a model structure to these measurements to obtain the variation of the steady state α terrace fraction fα as a function of growth conditions, as well as the relaxation times trel of fα upon changing conditions. These results are compared to calculated dynamics based on a BCF model for a system with alternating step types to quantify the differences in the attachment rates at A and B steps.

Results

Calculated surface X-ray scattering with alternating step types

We present calculations showing how the intensity distribution along the CTRs is sensitive to the fraction of the surface covered by α or β terraces. Our calculations include the effect of surface reconstruction, using relaxed atomic coordinates that have been obtained previously. For a vicinal surface, the CTRs are tilted away from the crystal axes, so that the CTRs from different Bragg peaks do not overlap. The X-ray reflectivity along the CTRs can be calculated by adding the complex amplitudes from the substrate crystal and the reconstructed overlayers, with proper phase relationships–. Details of our calculations are given in a separate paper.

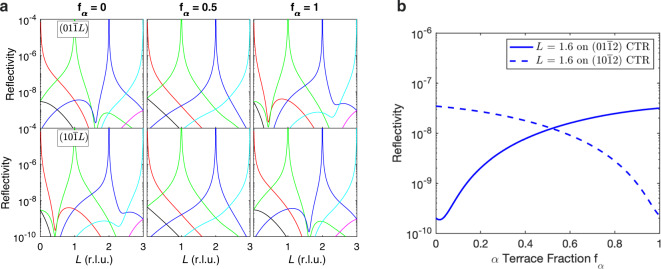

Figure 3a shows calculated intensity distributions along (011¯L) and (101¯L) CTRs for the GaN (0001) surface, demonstrating how their L-dependences vary with fα. Bragg peak locations have integer indices H0K0L0 in reciprocal lattice units; these indices identify the CTR associated with each peak. For this comparison, we use the 3H(T1) surface reconstruction and a fixed surface roughness, independent of fα, as discussed in the “Methods” section below and Supplementary Discussion . The same qualitative behavior is obtained using other surface reconstructions. For fα = 0 and fα = 1, the regions between the Bragg peaks have alternating stronger and weaker intensities, with the alternation being opposite for (011¯L) and (101¯L). For fα = 0.5, the intensities between all Bragg peaks are about the same, and there is no difference between the (011¯L) and (101¯L) CTRs. As required by symmetry, the (011¯L) CTRs with fα = X are identical to the (101¯L) CTRs with fα = 1 − X, for any value X. Figure 3b shows calculations of the reflectivity as a function of fα at positions near L = 1.6 on the (011¯2) and (101¯2) CTRs. The variation in reflectivity is almost monotonic in fα at these positions. These curves are used below to extract fα(t) during dynamic transitions.

Fig. 3

Calculated CTR intensities for a vicinal GaN (0001) surface.

a Top and bottom rows show the families of CTRs along (011¯L) and (101¯L), respectively. Black, red, green, blue, cyan, and magenta curves are for CTRs from the L0 = −1 to 4 Bragg peaks, respectively. Values of fα for each column are given at the top. b Reflectivity of selected CTRs as a function of terrace fraction fα for fixed values of L = 1.6.

In situ X-ray scattering measurements during growth

We studied four OMVPE conditions having different net growth rates at the same temperature 1076 ± 5 K, summarized in Table 1 (see “Methods” for further details). The substrate used was a GaN single crystal. Figure 4a shows its initial surface morphology determined by ex situ atomic force microscopy (AFM). One can see straight steps almost perpendicular to the y or [011¯0] direction over large areas. An analysis of the step spacing shows a slight tendency towards pairing, with one of the two alternating terrace types having an area fraction of 0.47. AFM is insensitive to whether this fraction corresponds to the α or β terraces. We also characterized the miscut angle by measuring the splitting of the CTRs. Figure 4b shows a transverse cut through the CTRs in the Qy direction near (000L) at L = 0.9. Both the AFM and X-ray measurements give a double-step spacing of w = 573 Å corresponding to a miscut angle of 0.52°. To relate the α terrace fraction to the behavior of A and B steps, it is critical to determine the sign of the step azimuth. By making measurements as a function of L, we verified that the peak at high Qy is the CTR coming from (0000), while the peak at low Qy is the (0002) CTR. This confirms that the downstairs direction of the vicinal surface is in the +y direction, as drawn in Fig. 1. It is also useful to know the precise angle of the step azimuth with respect to the crystal planes, which determines the minimum kink density and thus the predicted values of some kinetic coefficients. X-ray measurements found this to be 5° off of the [011¯0] direction towards [101¯0], which gives a maximum kink spacing of 33 Å. The kink spacing could be smaller due to thermally generated kinks, as discussed in Supplementary Discussion . With this low-dislocation-density substrate and the low growth rates used, the previously reported instability to step bunching during growth was not observed.

Growth conditions studied.

| Growth condition index | TEGa flow (μmol min−1) | H2 frac. in carrier (%) | Net growth rate G (monolayer s−1) | | Measured values from CTR fits | Best fit from BCF model |

|---|

| 1 | 0.000 | 50 | −0.0018 | fαss | 0.111 ± 0.013 | 0.136 |

| 2 | 0.000 | 0 | 0.0000 | fαss | 0.461 ± 0.018 | 0.440 |

| 3 | 0.033 | 50 | 0.0109 | fαss | 0.811 ± 0.014 | 0.836 |

| 4 | 0.033 | 0 | 0.0127 | fαss | 0.868 ± 0.011 | 0.847 |

| 1–2 | | | | trel | 2200 ± 200 s | 2478 |

| 2–4 | | | | trel | 340 ± 30 s | 331 |

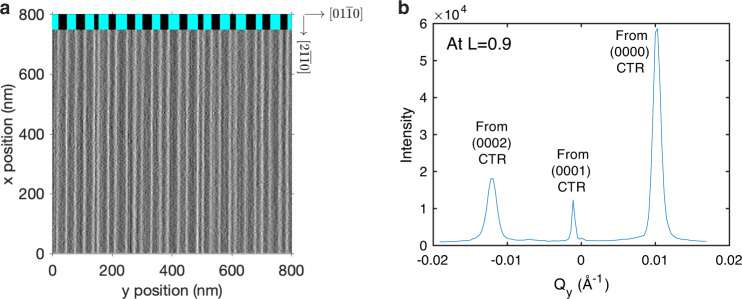

Fig. 4

Imaging and scattering from steps.

a AFM image of steps of height c/2 (2.6 Å) on the vicinal GaN substrate used in X-ray measurements. To emphasize the positions of steps, we plot the amplitude error signal, which is proportional to the height gradient in the scan direction (y). Image was obtained ex situ at room T after an anneal for 300 s at 1118 K in zero-growth conditions (0% H2, 0 TEGa). Average fraction over a 2 × 2 μm2 area of terrace family marked black at top is 0.47. The average double-step spacing of w = 573 Å corresponds to a miscut angle of tan−1(c/w)=0.52∘. b Profile of split CTRs from the vicinal surface, measured at T = 1170 K during growth at 0.053 μmol min−1 TEGa and 50% H2. The splitting of the CTRs ΔQy = 0.0110 Å−1 corresponds to a miscut angle of tan−1[ΔQy/(2π/c)]=0.52∘, in agreement with the AFM result.

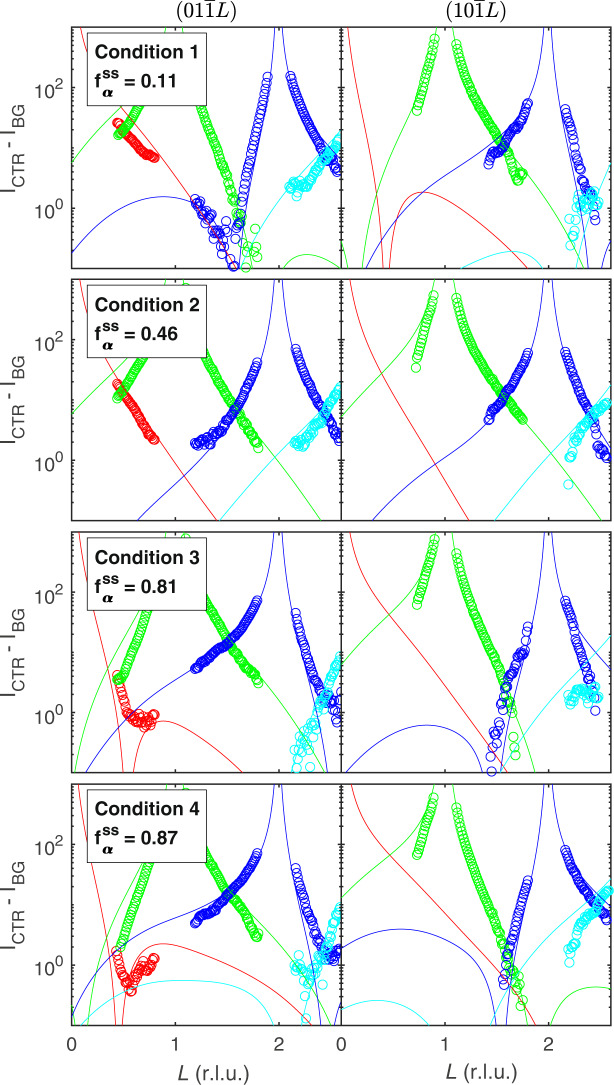

Figure 5 shows the measured steady state CTR intensities as a function of L, for both the (011¯L) and (101¯L) CTRs and at all four conditions. The qualitative behavior agrees with that expected from a variation in fα shown in Fig. 3a, with alternating higher and lower intensities between the Bragg peaks under some conditions, and opposite behavior of the two CTRs.

Fig. 5

Measured and calculated crystal truncation rods.

Symbols show measured net intensities of the (011¯L0) CTRs and the (101¯L0) CTRs families (left and right) for CTRs from the L0 = 0, 1, 2, and 3 Bragg peaks at each of four conditions. Curves show fits of all CTRs to obtain steady state α terrace fraction fαss at each condition.

Steady state and dynamics of terrace fraction during growth

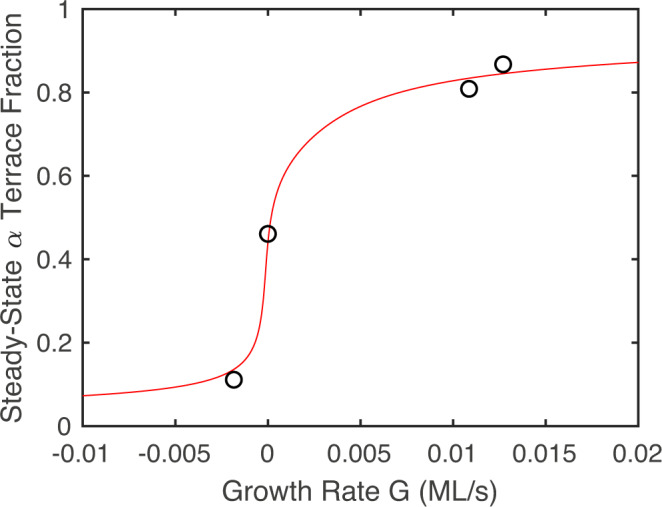

To obtain values of the steady state terrace fraction fαss for each of the four conditions, we fit calculated CTR intensities to the measured profiles. We performed fits using different possible surface reconstructions (see “Methods” for further details). While the 3H(T1) reconstruction gives the best fit to all conditions, similar fαss values are obtained using alternative reconstructions. For each condition, both the (011¯L) and (101¯L) CTRs were simultaneously fit. The values of fαss obtained as a function of net growth rate G are given in Table 1. The marked increase in fαss as G is increased reveals the qualitative difference between the kinetics at A and B steps during OMVPE of GaN: adatom attachment coefficients for A steps are larger. Thus, a surface with initially balanced α and β terrace fractions at zero net growth rate will evolve to one with higher fαss during positive net growth, because of the initially higher adatom attachment rate at the A steps. Likewise, during evaporation the initially higher detachment rate at A steps will give a lower fαss.

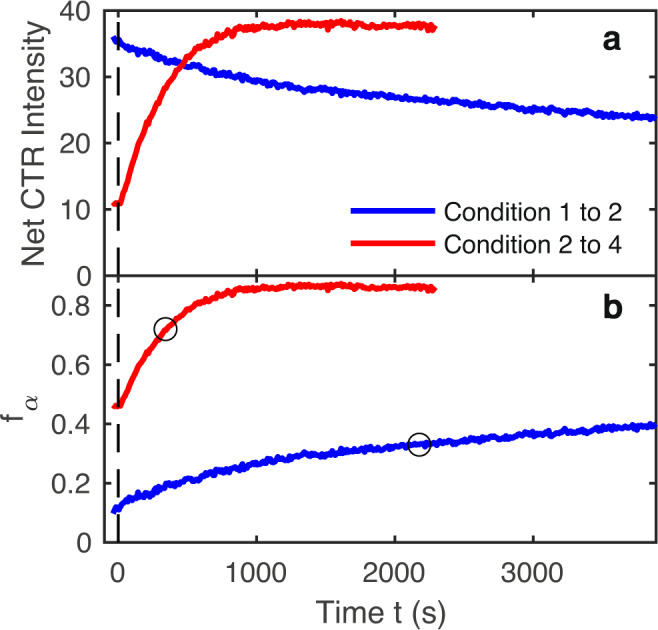

We also observed the dynamics of the change in fα by recording the intensity at a fixed detector position as a function of time before and after an abrupt change between conditions, as shown in Fig. 6a. We chose positions near L = 1.6 where the X-ray reflectivity R changes almost monotonically with fα, as shown in Fig. 3b. It is thus straightforward to obtain fα(t) from the intensity evolution using the calculated R(fα), as shown in Fig. 6b. The characteristic 1/e relaxation times trel were 2200 ± 200 and 340 ± 30 s for the transitions from conditions 1 to 2 and 2 to 4, respectively.

Fig. 6

Dynamics following a change of condition at t = 0.

a Measured CTR intensities. b Calculated terrace fractions fα. Blue curves: conditions 1–2 on the (101¯2) CTR at L = 1.627. Red curves: conditions 2–4 on the (011¯2) CTR at L = 1.603. Circles show 1/e relaxation times trel of 2200 ± 200 and 340 ± 30 s, respectively.

BCF model for surface with alternating step types

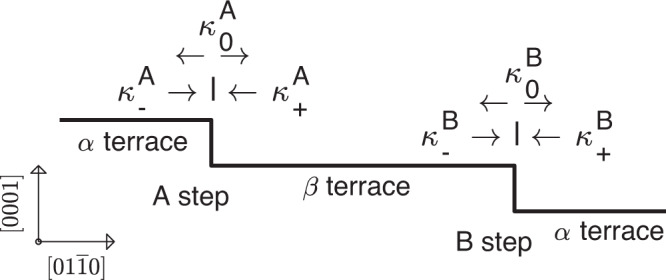

To quantitatively relate the behavior of the terrace fraction to the kinetic properties of A and B steps, we have developed a model based on BCF theory. Such models have been used extensively to understand growth behavior such as the step-bunching instability, pairing of steps, and competitive adsorption, typically where all steps in a sequence are equivalent. In our model, we consider an alternating sequence of two types of terraces, α and β, and two types of steps, A and B, with properties that can differ, as shown in Fig. 7. Related BCF models with an alternating step or terrace properties have appeared previously,,,–. We include the effects of step transparency (i.e., adatom transmission across steps) and step–step repulsion.

Fig. 7

Schematic of alternating terraces and steps for the BCF model.

Vicinal {0001} surfaces of HCP crystals have alternating α and β terraces separated by A and B steps. Notations are indicated for the kinetic coefficients for adatom attachment from below and above and for adatom transmission. Schematic of alternating terraces and steps of BCF model for HCP basal-plane surfaces, showing kinetic coefficients for the A and B steps.

The rate of change in the adatom density per unit area ρi on terrace type i = α or β is written as

where

D is the adatom diffusivity,

τ is the adatom lifetime before evaporation, and

F is the deposition flux of adatoms per unit time and area. The four boundary conditions for the flux at the steps terminating each type of terrace can be written as

As shown in Fig.

7,

κ+j and

κ−j are the kinetic coefficients for adatom attachment at a step of type

j =

A or

B from below or above, respectively, and

κ0j is the kinetic coefficient for transmission across the step. The + or − superscripts on

ρi and ∇

ρi indicate evaluation at the downhill or uphill terrace boundaries, respectively. We consider the overall vicinal angle of the surface to fix the sum

w of the widths of

α and

β terraces, which are thus

fαw and (1 −

fα)

w. We also assume relations between the equilibrium adatom densities

ρeqj at the steps and the terrace widths that reflect an effective repulsion between the steps owing to entropic and strain effects

,

where

ρeq0 is the equilibrium adatom density at zero growth rate, and the adatom chemical potentials

μj at steps of type

j =

A or

B have a dependence on

fα given by

where

ℓ is the step repulsion length and

fα0 is the terrace fraction at zero growth rate.

To solve this model, we develop a quasi-steady state expression for the dynamics of the terrace fraction fα. Under fairly general assumptions, the behavior of fα can be written as a function of the net growth rate,

This is simply the difference between the deposition

F and a uniform evaporation

ρeq0/τ, converted to monolayer per second (ML s

−1) using the site density

ρ0 per half-unit-cell-thick ML. The rate of change in

fα is

where we have introduced the net steady state and dynamic kinetic coefficient functions

Kss(

fα) and

Kdyn(

fα), which in the general case depend on all six

κxj coefficients

.

The full steady state dfα/dt = 0 is obtained at a growth rate of

This equation for

Gss(

fα) can be inverted to obtain the steady state value

fαss as a function of

G. The sign of d

Gss/d

fα and thus

dfαss/dG is determined by the sign of

Kss. General expressions for

Kss show that in most cases, such as that found here, its sign is positive when the kinetic coefficients for

A steps are larger than those for

B steps

.

To calculate BCF model results to compare with the experimental conditions, we make three assumptions: (1) the only parameter affected by the TEGa supply rate is the deposition flux F; (2) the only parameter affected by the carrier gas composition (0 or 50% H2) is the adatom lifetime τ; and (3) F and τ enter only through the net growth rate G given by Eq. (), listed in Table 1 for each condition. We use the known values ρ0=2a−2/3=1.13×1019 m−2 and w=c/sin(0.52∘)=5.73×10−8 m, where a = 3.20 × 10−10 m and c = 5.20 × 10−10 m are the lattice parameters of GaN at the growth temperature. We performed fits to the measured quantities (four fαss and two trel) using the general expressions for Kss(fα) and Kdyn(fα). The relaxation times for the model were calculated by integrating Eq. () to obtain fα(t), and then extracting the relaxation time with the same normalization procedure used for the experimental data. The best fit, shown in Fig. 8, was obtained in the limit in which the κ+A coefficient is large, while the κ−A, κ−B, and κ0A coefficients approach zero. In this case, Kss(fα) and Kdyn(fα) can be written as

Note that

κ+A does not appear in these expressions because in this limit other microscopic processes are rate-limiting. We can fit the measurements directly using these expressions to obtain the four parameters

D/κ+B = 1.9 × 10

−8 m,

D/κ0B = 1.1 × 10

−8 m,

Dρeq0ℓ3 = 3.3 × 10

−23 m

3 s

−1, and

fα0 = 0.44. Table

1 compares the six measured quantities (four

fαss and two

trel) to the best-fit values calculated from the BCF model.

Fig. 8

Steady state α terrace fraction fαss as a function of growth rate G.

Circles are experimental values given in Table 1, showing monotonic increase of fαss with increasing G. Curve is best-fit BCF model calculation; also fit simultaneously with these four points were the two relaxation times trel given in Table 1.

Discussion

To interpret the combined parameters obtained from the fits, it is useful to estimate the adatom diffusivity D and equilibrium adatom density ρeq0. Ab initio calculations of the activation energy for Ga diffusion on the Ga-terminated (0001) surface have given values of ΔHm = 0.4 and 0.5 eV, and similar values have been obtained for 3d transition metal adatoms. If we estimate the diffusivity from the ab initio calculations using D=a2νexp(ΔSm/k)exp(−ΔHm/kT), with a = 3.2 × 10−10 m, ν = 1013 s−1, ΔSm = 0, and ΔHm = 0.4 eV, we obtain D = 1.4 × 10−8 m2 s−1 at T = 1073 K. An analysis of spatial correlations in surface morphology of GaN films indicated a cross-over at T = 1073 K from surface diffusion transport to evaporation/condensation transport at a length scale of λ = 1.5 × 10−6 m for OMVPE growth with H2 present in the carrier gas. Thus, the adatom lifetime τ can be estimated as τ = λ2/D = 1.7 × 10−4 s under these conditions. Using our observed negative net growth rate for F = 0 of G=−ρeq0/(ρ0τ)=−0.00184 ML s−1, this gives a value for the equilibrium adatom density of ρeq0=3.4×1012 m−2. Using these estimates for D and ρeq0, the parameters obtained from the mixed kinetics fit imply kinetic coefficients of κ+B=0.74 m s−1 and κ0B=1.3 m s−1, and a step repulsion length of ℓ = 9 × 10−10 m.

Although it has not been possible to use scanning-probe microscopy to observe the orientation difference of α and β terraces on vicinal basal-plane surfaces of HCP-type systems, our results show that this difference is robustly revealed by surface X-ray scattering. In situ X-ray measurements during growth can determine the fraction covered by each terrace, and thus distinguish the dynamics of A and B steps. While the CTR calculations presented here are for wurtzite-structure GaN, this method applies to many other HCP-type systems with a 63 screw axis, including other compound semiconductors, as well as one-third of the crystalline elements and many more complex crystals.

The BCF model presented here makes predictions for the behavior of the α terrace fraction fα at steady state and during transients, in terms of surface properties such as the adatom diffusivity D and step kinetic coefficients κxj. In particular, the steady state fraction fαss is predicted to depend only on the net growth rate G=(F−ρeq0τ)/ρ0, rather than individually on the deposition rate F or the adatom lifetime τ. The positive or negative slope of fαss(G) is determined by the sign of a combined kinetic parameter Kss.

Our primary experimental result, the positive slope of fαss(G), determines the basic nature of the adatom attachment kinetics at A and B steps for GaN (0001) OMVPE. In general, this positive slope implies that A steps have faster kinetics than B steps, that is, the attachment coefficients κxA are larger than the κxB. While a similar general shape of fαss(G) is produced by many combinations of the parameters in the BCF model that have faster A than B step kinetics, the best fit to our measurements is obtained in the specific limit of Eqs. () and ()). In this limit, the A step has much faster attachment kinetics than the B step, with κ+A>>κ+B. This limit also indicates that both A and B steps have standard positive ES barriers, with adatom attachment from below significantly faster than from above for the same supersaturation, and that the A step is nontransparent. We find that fα0 differs only slightly from the symmetrical value of 1/2.

In comparing the observed values of the step kinetic coefficients to predictions, the 5° rotation of the step azimuth away from [011¯0] is potentially important, since it determines the minimum average kink spacing on the steps to be 33 Å, as discussed in Supplementary Discussion . We expect that this relatively small kink spacing will tend to produce higher predicted values of the attachment coefficients κ+j and κ−j and lower values of the transmission coefficients κ0j, since attachment occurs when adatoms at a step diffuse along it to find a kink, while transmission occurs when the adatom detaches from the step onto the opposite terrace before it finds a kink. Because the transmitted adatom must traverse the barriers on both sides of the step independent of whether it arrives from above or below, κ0j does not depend on the direction.

Our conclusion that A steps on GaN (0001) have higher attachment coefficients than B steps agrees with the original qualitative prediction, and motivates further quantitative theory development beyond that carried out to date. In several previous studies,–, various assumptions can lead to the opposite conclusion, as described below. Both the predicted and observed step behavior can depend upon the chemical environment (e.g., OMVPE vs. MBE) and how it passivates the step edges. For example, arguments regarding dangling bonds at steps, depend on the effects of very high or low V/III ratios and the presence of NH3 or H2. Likewise, KMC studies– typically make assumptions about bonding that determine the rates of atomic-scale processes at steps. Detailed ab initio predictions of kinetic barriers and adsorption energies at steps under MBE and OMVPE conditions– show that they depend strongly on the chemical environment and resulting surface reconstruction. To date, these calculations have been carried out for the Ga(T4), NH(H3) + H(T1), and NH(H3) + NH2(T1) reconstructions. In future theoretical work, it would be useful to consider the specific step-edge structures associated with the 3H(T1) reconstruction found here and in recent calculations for the OMVPE environment. Having an accurate model for atomic incorporation at steps can have important practical implications for advanced GaN devices, for example, laser diodes and white LEDs, by allowing control of interface morphology and incorporation of alloying elements such as In,.

We have demonstrated this method using a micron-scale X-ray beam to satisfy the requirement that the illuminated surface region has a well-defined step azimuth. With current synchrotron X-ray sources, it is convenient to increase the signal rate using a wide-energy-bandwidth pink beam. The higher brightness synchrotron sources soon to come online worldwide will make it possible to perform this type of experiment with highly monochromatic beams, greatly increasing the in-plane resolution of the CTR measurements.

Methods

Calculated CTR intensities

Derivation of the CTR calculations for miscut surfaces with alternating terrace terminations is provided in a separate paper. As described in Supplementary Discussion , in fits shown in Table 2, and in recent predictions, we expect that the GaN surface under OMVPE conditions has a 3H(T1) reconstruction, in which 3 of every 4 Ga atoms in top-layer sites shown in Fig. 2 are bonded to an adsorbed hydrogen. The calculations in Fig. 3a include the effect of this reconstruction, with equal fractions of all reconstruction domains on both terraces. Since no fractional-order diffraction peaks from long-range-ordered reconstructions are observed in experiments, we expect that the domain structure has a short correlation length and all domains are present. We use a surface roughness of σR = 0.74 Å to match the experimental fits described below.

Values of fit parameters for each of four OMVPE conditions.

| Growth condition index | Reconstruction | fαss | σR | χ2 |

|---|

| 1 | 3H(T1) | 0.111 | 0.75 | 106 |

| Ga(T4) | 0.144 | 1.26 | 130 |

| NH(H3) + H(T1) | 0.098 | 0.94 | 187 |

| NH(H3) + NH2(T1) | 0.106 | 0.88 | 200 |

| NH(H3) | 0.095 | 0.91 | 167 |

| 2 | 3H(T1) | 0.461 | 0.93 | 57 |

| Ga(T4) | 0.476 | 1.26 | 81 |

| NH(H3) + H(T1) | 0.460 | 1.15 | 76 |

| NH(H3) + NH2(T1) | 0.460 | 1.11 | 67 |

| NH(H3) | 0.459 | 1.13 | 99 |

| 3 | 3H(T1) | 0.811 | 0.85 | 118 |

| Ga(T4) | 0.670 | 1.46 | 218 |

| NH(H3) + H(T1) | 0.876 | 1.19 | 205 |

| NH(H3) + NH2(T1) | 0.869 | 1.15 | 248 |

| NH(H3) | 0.869 | 1.16 | 168 |

| 4 | 3H(T1) | 0.868 | 0.47 | 80 |

| Ga(T4) | 0.942 | 1.06 | 112 |

| NH(H3) + H(T1) | 0.892 | 0.90 | 174 |

| NH(H3) + NH2(T1) | 0.879 | 0.85 | 220 |

| NH(H3) | 0.891 | 0.87 | 135 |

In situ microbeam X-ray experiments

We performed in situ measurements of the CTRs in the OMVPE environment at the Advanced Photon Source beamline 12ID-D. At an incidence angle of 2°, the 10 μm X-ray beam illuminated an area of 10 × 300 μm. To obtain sufficient signal, we used a wide-bandwidth pink beam setup,. Details of the measurements and data analysis are given in Supplementary Methods . Two types of measurements were performed. We determined the steady state terrace fractions fαss under four different growth/evaporation conditions by scanning the detector along the (011¯L) and (101¯L) CTRs while continuously maintaining steady state growth or evaporation. We also observed the dynamics of fα after an abrupt change in conditions.

Under the conditions studied, deposition is transport limited, with the deposition rate proportional to the supply of the Ga precursor (triethylgallium, TEGa), with a large excess of the N precursor (NH3) constantly supplied. We investigated conditions of zero deposition (no supply of TEGa) as well as deposition at a TEGa supply of 0.033 μmol min−1. The NH3 flow in both cases was 2.7 s.l.p.m. or 0.12 mol min−1, and the total pressure was 267 mbar. The V/III ratio during deposition was thus 3.6 × 106. For both of these conditions, we studied two carrier gas compositions: 50% H2 + 50% N2 and 0% H2 + 100% N2. The addition of H2 to the carrier gas enhances evaporation of GaN, so that the net growth rate (deposition rate minus evaporation rate) is slightly lower; at zero deposition rate, the net growth rate is negative. We determined the net growth rate for all four conditions as described in Supplementary Methods . These values are given in Table 1. Substrate temperatures were calibrated to within ±5 K using laser interferometry from a standard sapphire substrate. While we used the same heater temperature for all conditions, the calibration indicates that the substrate temperature was slightly higher in 50% H2 (1080 K) than in 0% H2 (1073 K). Based on an expected activation energy of ~ 0.4 eV for surface kinetics, this temperature difference produces a negligible (few percent) change in kinetic coefficients.

Fits to steady state CTRs

For each growth condition, fits were performed of the calculated CTR intensities to the measured profiles of the (011¯L) and (101¯L) CTRs. In addition to a single value of fα, parameters varied in the fit included a single surface roughness σR and two intensity scale factors, one for each CTR. We fit to log(I) with equal weighting of all points. Fits were done using different possible surface reconstructions. Supplementary Fig. shows the calculated reconstruction phase diagram for the GaN (0001) surface in the OMVPE environment, as a function of Ga and NH3 chemical potentials. Based on the chemical potential values that correspond to our experimental conditions estimated in Supplementary Discussion , shown by the green rectangle, we considered the five reconstructions highlighted in Supplementary Fig. . (The estimate for ΔμGa has a large uncertainty because it depends on the nitrogen potential produced by decomposition of NH3.) Table 2 shows the values of steady state terrace fraction fαss, surface roughness σR, and the goodness-of-fit parameter χ2 from fits to reflectivity at four conditions for each of five reconstructions. The qualitative results for the variation of fαss with growth condition are independent of which reconstruction is assumed: fαss increases monotonically as the net growth rate G increases. The 3H(T1) reconstruction gives the best fit (minimum χ2) of the five potential reconstructions, for all four conditions. This is consistent with recent results on GaN (0001) reconstructions in the OMVPE environment, which found a phase stability region for the 3H(T1) structure even larger than that shown in Supplementary Fig. . Figure 5 compares the fits with the 3H(T1) reconstruction to the measured CTR intensities.

Extracting terrace fraction dynamics

We first convert the intensity evolution near L = 1.6 to reflectivity R(t) by normalizing it to match the predicted change in reflectivity for the transition in fαss. We then invert the R(fα) relation calculated for the experimental L value, shown in Fig. 3b, to obtain fα(t). For simplicity, we assume the surface roughness is not a function of growth condition, and use the average value of σR = 0.74 Å from the 3H(T1) fits to calculate R(fα). If the surface roughness were to vary with condition by the amounts shown in Table 2, this would explain only a small fraction of the observed changes (decrease of 7% out of 40% for the transition from conditions 1 to 2, and increase of 16% out of 350% for the transition from conditions 2 to 4). The resulting fα(t) are shown in Fig. 6b. To extract a characteristic relaxation time for each transition, we interpolate the normalized the change [fα(t) − fα(∞)]/[fα(0) − fα(∞)] to obtain the time at which it equals 1/e.

Fits of BCF theory to experimental results

The general expressions for Kss(fα) and Kdyn(fα) involve nine unknown quantities (D, ρeq0ℓ3, fα0, and the six κxj) to be determined or constrained by the measurements. This is a challenge because there are only six measured quantities (four steady state α terrace fractions fαss at different growth rates G, and two relaxation times for transitions in G.) The best fit allowing all nine parameters to vary was first determined by a numerical Levenberg–Marquardt nonlinear regression search algorithm. This minimized the goodness-of-fit parameter χ2≡∑[(yi−yicalc)/σi]2, where the yi and σi are the six measured quantities and their uncertainties. To estimate the uncertainties in the fαss, we multiplied those obtained in the fits to the 3H(T1) reconstruction by a factor of 4, to account for the uncertainties in the atomic coordinates used. We estimated the uncertainty in the trel to be 10%.

This initial fit found that the minimum χ2 occurs in the region of parameter space in which the κ+A coefficient is large, while the κ−A, κ−B, and κ0A coefficients approach zero. In this case, the limiting expressions (Eqs. () and ()) for Kss(fα) and Kdyn(fα) involve only the four unknown quantities D/κ+B, D/κ0B, Dρeq0ℓ3, and fα0. A final fit using Eqs. () and ()) allowing only these four parameters to vary gave the same solution as the nine parameter fit.

Peer review information: Nature Communications thanks Henryk Turski and other, anonymous, reviewers for their contributions to the peer review of this work. Peer review reports are available.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

The online version contains supplementary material available at 10.1038/s41467-021-21927-5.

Acknowledgements

This work was supported by the US Department of Energy (DOE), Office of Science, Office of Basic Energy Sciences, Materials Science and Engineering Division. Experiments were performed at the Advanced Photon Source beamline 12ID-D, a DOE Office of Science user facility operated by Argonne National Laboratory.

Author contributions

All authors contributed to initial discussions motivating the experiments and analysis. G.J., C.T., M.J.H., J.A.E., and G.B.S. developed the microbeam surface X-ray scattering method and carried out the measurements. W.W. provided calculated atomic coordinates for the various surface reconstructions. D.X., C.T., P.Z., and G.B.S. developed the CTR and BCF expressions used in the analysis. G.J. and G.B.S. analyzed the results. All coauthors contributed to drafting and editing the manuscript.

Data availability

Data supporting the findings of this study are available within the article and its file and are available in electronic form from the corresponding author on reasonable request.

Competing interests

The authors declare no competing interests.

References

Burton W, Cabrera N, Frank F. The growth of crystals and the equilibrium structure of their surfaces. Philos. Trans. R. Soc. Lond. Ser. A1951. 243: 299 doi: 10.1098/rsta.1951.0006

Woodruff DP. How does your crystal grow? a commentary on Burton, Cabrera and Frank (1951) The growth of crystals and the equilibrium structure of their surfaces. Philos. Trans. R. Soc. Ser. A2015. 373: 20140230 doi: 10.1098/rsta.2014.0230

Verma AR. CI. Observations on carborundum of growth spirals originating from screw dislocations. Philos. Mag.1951. 42: 1005-1013 doi: 10.1080/14786445108561345

van Enckevort WJP, Bennema P. Interlacing of growth steps on crystal surfaces as a consequence of crystallographic symmetry. Acta Crystallogr. Sec. A2004. 60: 532-541 doi: 10.1107/S0108767304015326

Turski H, . Nonequivalent atomic step edges - role of gallium and nitrogen atoms in the growth of InGaN layers. J. Cryst. Growth2013. 367: 115-121 doi: 10.1016/j.jcrysgro.2012.12.026

Kaufmann NAK, . Critical impact of Ehrlich-Schwöbel barrier on GaN surface morphology during homoepitaxial growth. J. Cryst. Growth2016. 433: 36-42 doi: 10.1016/j.jcrysgro.2015.06.013

Xie MH, . Anisotropic step-flow growth and island growth of GaN(0001) by molecular beam epitaxy. Phys. Rev. Lett.1999. 82: 2749-2752 doi: 10.1103/PhysRevLett.82.2749

Giesen M. Step and island dynamics at solid/vacuum and solid/liquid interfaces. Prog. Surf. Sci.2001. 68: 1-154 doi: 10.1016/S0079-6816(00)00021-6

Heying B, . Dislocation mediated surface morphology of GaN. J. Appl. Phys.1999. 85: 6470-6476 doi: 10.1063/1.370150

S Vézian S, Massies J, Semond F, Grandjean N. Surface morphology of GaN grown by molecular beam epitaxy. Mater. Sci. Eng. B2001. 82: 56-58 doi: 10.1016/S0921-5107(00)00707-8

Xie MH, Gong M, Pang EKY, Wu HS, Tong SY. Origin of triangular island shape and double-step bunching during GaN growth by molecular-beam epitaxy under excess Ga conditions. Phys. Rev. B2006. 74: 085314 doi: 10.1103/PhysRevB.74.085314

Zheng H, Xie MH, Wu HS, Xue QK. Kinetic energy barriers on the GaN(0001) surface: a nucleation study by scanning tunneling microscopy. Phys. Rev. B2008. 77: 045303 doi: 10.1103/PhysRevB.77.045303

Pristovsek M, . Surface reconstructions of (0001) AlN during metal-organic vapor phase epitaxy. Phys. Stat. Sol. B2017. 254: 1600711 doi: 10.1002/pssb.201600711

Chen Y, Ko H-J, Hong S-K, Yao T, Segawa Y. Morphology evolution of ZnO(0001¯) surface during plasma-assisted molecular-beam epitaxy. Appl. Phys. Lett.2002. 80: 1358-1360 doi: 10.1063/1.1454229

Załuska-Kotur MA, Krzyżewski F, Krukowski S. Surface patterns due to step flow anisotropy formed in crystal growth process. J. Non-Cryst. Solids2010. 356: 1935-1939 doi: 10.1016/j.jnoncrysol.2010.05.029

Załuska-Kotur MA, Krzyżewski F, Krukowski S. Double step structure and meandering due to the many body interaction at GaN(0001) surface in N-rich conditions. J. Appl. Phys.2011. 109: 023515 doi: 10.1063/1.3536516

Chugh M, Ranganathan M. Lattice kinetic Monte Carlo simulation study of the early stages of epitaxial GaN (0001) growth. Appl. Surf. Sci.2017. 422: 1120-1128 doi: 10.1016/j.apsusc.2017.06.067

Xu D, Zapol P, Stephenson GB, Thompson C. Kinetic Monte Carlo simulations of GaN homoepitaxy on c- and m-plane surfaces. J. Chem. Phys.2017. 146: 144702 doi: 10.1063/1.4979843

Akiyama T, Ohka T, Nakamura K, Ito T. Ab initio study for adsorption and desorption behavior at step edges of GaN(0001) surface. J. Cryst. Growth2020. 532: 125410 doi: 10.1016/j.jcrysgro.2019.125410

Akiyama T, Ohka T, Nakamura K, Ito T. Ab initio study for adsorption and desorption behavior at step edges of AlN(0001) and GaN (0001) surfaces. Jpn. J. Appl. Phys.2020. 59: SGGK03 doi: 10.7567/1347-4065/ab6566

Ohka T, Akiyama T, Pradipto AM, Nakamura K, Ito T. Effect of step edges on adsorption behavior for GaN (0001) surfaces during metalorganic vapor phase epitaxy: an ab initio study. Cryst. Growth Des.2020. 20: 4358-4365 doi: 10.1021/acs.cgd.0c00117

Avery AR, Dobbs HT, Holmes DM, Joyce BA, Vvedensky DD. Nucleation and growth of islands on GaAs surfaces. Phys. Rev. Lett.1997. 79: 3938-3941 doi: 10.1103/PhysRevLett.79.3938

Jo M, . Self-limiting growth of hexagonal and triangular quantum dots on (111)A. Cryst. Growth Des.2012. 12: 1411-1415 doi: 10.1021/cg201513m

Kalff M, Comsa G, Michely T. How sensitive is epitaxial growth to adsorbates?. Phys. Rev. Lett.1998. 81: 1255-1258 doi: 10.1103/PhysRevLett.81.1255

Yin C, . Shape prediction of two-dimensional adatom islands on crystal surfaces during homoepitaxial growth. Appl. Phys. Lett.2009. 94: 183107 doi: 10.1063/1.3130091

Walkosz W, Zapol P, Stephenson GB. Metallicity of InN and GaN surfaces exposed to NH3. Phys. Rev. B2012. 85: 033308 doi: 10.1103/PhysRevB.85.033308

Munkholm A, Brennan S. Influence of miscut on crystal truncation rod scattering. J. Appl. Crystallogr.1999. 32: 143-153 doi: 10.1107/S0021889898005159

Trainor TP, Eng PJ, Robinson IK. Calculation of crystal truncation rod structure factors for arbitrary rational surface terminations. J. Appl. Crystallogr.2002. 35: 696-701 doi: 10.1107/S0021889802013985

Petach TA, Mehta A, Toney MF, Goldhaber-Gordon D. Crystal truncation rods from miscut surfaces. Phys. Rev. B2017. 95: 184104 doi: 10.1103/PhysRevB.95.184104

Ju G, . Crystal truncation rods from miscut surfaces with alternating terminations. Phys. Rev. B2021. 103: 125402 doi: 10.1103/PhysRevB.103.125402

Guin L, Jabbour ME, Shaabani-Ardali L, Benoit-Maréchal L, Triantafyllidis N. Stability of vicinal surfaces: Beyond the quasistatic approximation. Phys. Rev. Lett.2020. 124: 036101 doi: 10.1103/PhysRevLett.124.036101

Hanada T. Thermodynamic model for metalorganic vapor-phase epitaxy of N-polar group-III nitrides in step-flow growth mode: hydrogen, competitive adsorption, and configuration entropy. Phys. Rev. Mater.2019. 3: 103404 doi: 10.1103/PhysRevMaterials.3.103404

Zhao R, Ackerman DM, Evans JW. Refined BCF-type boundary conditions for mesoscale surface step dynamics. Phys. Rev. B2015. 91: 235441 doi: 10.1103/PhysRevB.91.235441

Sato M. Effect of step permeability on step instabilities due to alternation of kinetic coefficients on a growing vicinal face. Eur. Phys. J. B2007. 59: 311-318 doi: 10.1140/epjb/e2007-00295-y

Reeber RR, Wang K. Lattice parameters and thermal expansion of GaN. J. Mater. Res.2000. 15: 40-44 doi: 10.1557/JMR.2000.0011

Zywietz T, Neugebauer J, Scheffler M. Adatom diffusion at GaN(0001) and (0001) surfaces. Appl. Phys. Lett.1998. 73: 487-489 doi: 10.1063/1.121909

Chugh M, Ranganathan M. Adsorbate interactions on the GaN(0001) surface and their effect on diffusion barriers and growth morphology. Phys. Chem. Chem. Phys.2017. 19: 2111-2123 doi: 10.1039/C6CP07254B

González-Hernández R, López-Pérez W, Moreno-Armenta MG, Jairo Arbey Rodríguez M. Adsorption and diffusion of 3d transition metal atoms on the GaN (0001) surface. J. Appl. Phys.2011. 110: 083712 doi: 10.1063/1.3653822

Shewmon, P. Diffusion in Solids 2nd edn (Springer, 1989).

Koleske DD, . Connection between GaN and InGaN growth mechanisms and surface morphology. J. Cryst. Growth2014. 391: 85-96 doi: 10.1016/j.jcrysgro.2014.01.010

Ranguelov B, Altman MS, Markov I. Critical terrace width for step flow growth: effect of attachment-detachment asymmetry and step permeability. Phys. Rev. B2007. 75: 245419 doi: 10.1103/PhysRevB.75.245419

Kempisty P, Kangawa Y. Evolution of the free energy of the GaN (0001) surface based on first-principles phonon calculations. Phys. Rev. B2019. 100: 085304 doi: 10.1103/PhysRevB.100.085304

Ju G, . An instrument for in situ coherent X-ray studies of metal-organic vapor phase epitaxy of III-nitrides. Rev. Sci. Instrum.2017. 88: 035113 doi: 10.1063/1.4978656

Ju G, . Characterization of the X-ray coherence properties of an undulator beamline at the advanced photon source. J. Synchrotron Radiat.2018. 25: 1036-1047 doi: 10.1107/S1600577518006501

Ju G, . Coherent X-ray spectroscopy reveals the persistence of island arrangements during layer-by-layer growth. Nat. Phys.2019. 15: 589-594 doi: 10.1038/s41567-019-0448-1