Spin thermoelectrics, an emerging thermoelectric technology, offers energy harvesting from waste heat with potential advantages of scalability and energy conversion efficiency, thanks to orthogonal paths for heat and charge flow. However, magnetic insulators previously used for spin thermoelectrics pose challenges for scale-up due to high temperature processing and difficulty in large-area deposition. Here, we introduce a molecule-based magnetic film for spin thermoelectric applications because it entails versatile synthetic routes in addition to weak spin-lattice interaction and low thermal conductivity. Thin films of CrII[CrIII(CN)6], Prussian blue analogue, electrochemically deposited on Cr electrodes at room temperature show effective spin thermoelectricity. Moreover, the ferromagnetic resonance studies exhibit an extremely low Gilbert damping constant ~(2.4 ± 0.67) × 10−4, indicating low loss of heat-generated magnons. The demonstrated STE applications of a new class of magnet will pave the way for versatile recycling of ubiquitous waste heat.

Spin-thermoelectrics have great promise for waste heat conversion, however scaling up is challenging for device using standard magnetic insulators. Here, Oh et al demonstrate the molecular-magnet, Prussian blue analogues as a viable candidate for spin-thermoelectrics.

Thermoelectric (TE) technologies offer energy harvesting from the most common form of energy “heat.” A TE device is solid state, highly reliable, environmentally friendly, and compact in comparison with other energy conversion generators, desirable features for collecting omnipresent heat energy. Spin TE (STE), an emerging generation of TE technologies, converts heat into electricity via the spin Seebeck effect (SSE) using a combination of two layers1–3. One is a magnetic insulator, where the temperature gradient induces the propagation of thermally exited spin wave, magnon4. The other layer is a nonmagnetic heavy metal, such as, Pt, W, and Ta with strong spin–orbit coupling for the effective spin–charge conversion via the inverse spin Hall effect (ISHE)5,6. An applied vertical heat flux in the ferromagnet/heavy-metal bilayer produces longitudinal electrical power as illustrated in Fig. 1a. The bilayer architecture of an STE device has several advantages over traditional TE modules3. For example, in conventional TEs the figure of merit (ZT = S2σ/κ, where S, σ, and κ are Seebeck coefficient, electrical conductivity, and thermal conductivity, respectively) of the energy conversion is strictly limited by the trade-off relationship between S and σ, as well as the Wiedemann–Franz law7. In STE, the orthogonal energy conversion between heat and charge transfer in different mediums is free from such fundamental limitations. Moreover, the STE device is readily scalable by simply extending the area of a bilayer film, whereas scaling of the conventional TE module involves with series connections of alternating p–n pitches3. Nonetheless, scaling of the STE device still necessitates the development of facile film processings of magnetic insulators.

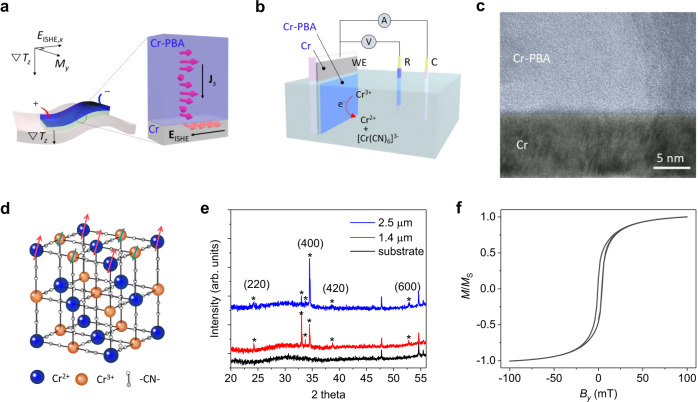

STE coating and characteristics of the Cr-PBA thin films.

a Schematic illustrations of STE energy conversion upon the vertical temperature gradient (∇Tz) and the mechanism of LSSE associated with thermally generated magnons and their conversion into a charge current via the ISHE. b Sketch of the ECD set-up for the Cr-PBA coating using a Cr thin film (10 nm) as a working electrode (WE), Pt counter electrode (C), and Ag/AgCl reference cell (R). c The cross-sectional TEM image of a Cr-PBA/Cr bilayer deposited on an oxidized silicon substrate. d Crystal structure of Cr[Cr(CN)6] displaying a ferrimagnetic configuration (antiparalleled Cr2+ (S = 2, t2g3eg1) and Cr3+ (S = 3/2, t2g3) spins via the superexchange coupling). e XRD spectra of Cr-PBA films with deposition time of 600 and 1200 s, which are 1.4 and 2.5 μm thick, respectively. f The magnetic hysteresis curve of the developed Cr-PBA film measured for in-plane applied magnetic field at 100 K.

Several inorganic magnetic insulators have been used for STE devices demonstrating effective STE energy conversion4,8,9. In particular, Yttrium iron garnet Y3Fe5O12 (YIG) has been most widely used for STE applications because its low Gilbert damping constant (α = 2.3 × 10−4) allows long-distance magnon propagation10. However, inorganic magnetic insulator films are not appropriate for practical STE applications due to scaling problem, because they are difficult to grow into a large area and in need of high temperature processing for crystallization3,11. In contrast, organic or molecular films are generally grown at a lower temperature, and their flexible synthetic routes could offer scalable deposition techniques. Organic-based magnetic film, for example, vanadium tetracyanoethylene (V(TCNE)x, x ~ 2) has shown effective spin-polarized carrier injection12,13 as well as coherent magnon generation and spin pumping14.

Prussian blue analog (PBA) is another family of molecule-based magnets with a molecular formula of AM1[M2(CN)6]x·nH2O (A is an alkali cation; M1 and M2 are transition metal ions). Substitution of transition metals at the M1 and M2 sites can produce a wide range of magnetic transition temperatures. For example, CrII[CrIII(CN)6]x·nH2O (Cr-PBA) showed Tc up to 240 K15–18 and VII[CrIII(CN)6] x·nH2O powder exhibited Tc up to 376 K19,20. Thus, PBAs are viable alternative magnetic insulators in STE devices with the advantage of versatile synthesis amenable for large area deposition at room temperature. Moreover, the molecule-based magnet may present weak spin–orbit coupling and lack of spin–lattice scatterings in addition to low thermal conductivity, which could lead to effective propagation of thermally excited magnons while retaining a greater temperature gradient.

In this work, we introduce a molecule-based magnet, Cr-PBA, as an alternative magnetic insulator for the magnon-mediated thermal-to-electrical energy conversion. The growth of Cr-PBA was done at room temperature by employing the electrochemical deposition (ECD) method, which could offer scalable production of thin films. A Cr (10 nm) thin film was used as a working electrode for ECD of Cr-PBA. The developed Cr-PBA/Cr bilayer can be directly utilized as an STE device with a seamless interface for effective spin pumping. The characterization of the developed STE device was done based on the configuration of the longitudinal spin SSE (LSSE)21–23, where the applied vertical temperature gradient is converted into the longitudinal electric voltage VLSSE. We show that our Cr-PBA/Cr bilayer, which has 5 mm length, 100 μm width, and 1.4 μm thickness of Cr-PBA, produces a robust spin Seebeck voltage ΔVLSSE/ΔT ~ 64.9 ± 3.13 μV/K at 100 K. We also confirmed the generation, transport, and detection of magnons in the Cr-PBA/Cr bilayer via ferromagnetic resonance (FMR) and FMR-driven ISHE experiments. The Cr-PBA films were found to have an extremely low Gilbert damping constant. Our study shows excitations and transfers of magnons in this hybrid magnet are very efficient, suggesting molecule-based magnets, along with their synthetic versatility, could be outstanding alternatives for various applications of spin caloritronics as well as magnon spintronics.

Figure 1a shows the schematic illustration of an STE coating over a wide area and the electrical energy harvesting from the thermally excited magnons. Here, the vertical temperature gradient (∇Tz) generates vertical propagation of magnons in a magnetic insulator, which induces thermally pumped spin angular moments at the interface. Then, the transferred vertical spin flow will be converted into a longitudinal charge current via ISHE, JLSSE ∝ Js × σ (Js and σ denote a thermally generated spin current vector and a spin polarization vector of electron, respectively). Figure 1b displays a schematic experimental set-up for ECD of the Cr-PBA film on a Cr metal. We employed a Cr thin film (10 nm) as a working electrode because it could provide relatively high spin–charge conversion, as evidenced in various literatures24,25. Heavy metals, such as Pt and Pd, are not appropriate for the working electrode due to a catalytic effect during the deposition. The Cr-PBA films are deposited through the reaction between [Cr(CN)6]3− and labile Cr2+ in the aqueous solution of K3Cr(CN)6 and CrCl3·H2O. A cross-sectional transmission electron microscope image of the developed Cr-PBA/Cr heterojunction is shown in Fig. 1c displaying a sharp interface. Further details of material preparation and characterization are described in “Methods” and Supplementary Note 1. Cyclic voltammetry curves for the observation of reductive reaction are shown in Supplementary Fig. 1. Cr-PBA has a structure consisting of interpenetrating face-centered cubic sublattices with ferrimagnetic spin alignments between Cr2+ (S = 2) and Cr3+ (S = 3/2) (Fig. 1d). X-ray diffraction spectra of Cr-PBA films are displayed in Fig. 1e. Results confirm a face-centered cubic phase of Cr-PBA with main peaks 24.2° (220), 34.5° (400), 38.7° (420), and 52.8° (600)26. The surface morphology of a Cr-PBA film probed by atomic force microscopy (AFM) is displayed in Supplementary Fig. 2. The magnetic hysteresis of the developed Cr-PBA film exhibits a coercivity of ~0.25 mT for in-plane applied magnetic field at 100 K (Fig. 1f). The Curie temperature of the developed Cr-PBA determined by Arrott plot method was Tc ~ 230 K (see Supplementary Fig. 3). Supplementary Fig. 4 displays a magnetization versus T3/2 plot exhibiting a good linearity following the Bloch T3/2 law. Fitting with M(T) = M0(1 − aT3/2) provides the value of slope a ~ 2.6 × 10−4 K−3/2. This value of the slope is much higher than those observed in Ni (7.5 × 10−6 K−3/2)27 and YIG (5.8 × 10−5 K−3/2)28. Thus, the excitations of magnons with low wave vectors would be more effective in our Cr-PBA film.

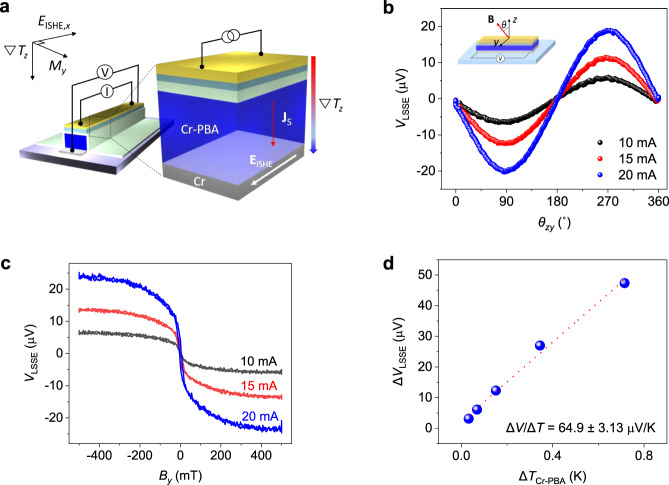

For the characterization of spin thermoelectricity of the developed heterojunction devices, a heat gradient was applied by Joule heating from an Au line on top of the device as shown in Fig. 2a. The on-chip Au line was also simultaneously used as a temperature sensor11,23. An electrical insulation between the top Au heater and Cr-PBA/Cr bilayer was done by the insertion of Al2O3 (130 nm)/Parylene (400 nm) films. The bottom of a device substrate (Si) was in thermal contact with a heat reservoir. Figure 2b shows the measured LSSE signals (VLSSE) as a function of zy angle of the applied magnetic field (1 T). VLSSE exhibits a sinusoidal behavior with the maximum magnitude when B and ∇Tz are perpendicular to each other because it is proportional to |Js × σ|. Figure 2c shows VLSSE as a function of applied By measured for different Iheater. VLSSE exhibits a small coercivity and nearly saturates at ~300 mT. With increasing Iheater, VLSSE also increases. The obtained ΔVLSSE (ΔVLSSE = |V(0.5 T) − V(−0.5 T)| for Iheater = 20 mA was 47.3 μV.

LSSE characterization for Cr-PBA/Cr heterojunction devices.

a A schematic illustration for the LSSE characterization of the Cr-PBA/Cr STE device. The temperature gradient was applied by Joule heating of a top Au line. The vertical flow of magnons pumps a pure spin current to the adjacent Cr layer. Then, the induced spin flow is converted into a longitudinal charge current producing electric field of EISHE. b VLSSE as a function of zy angle of the applied magnetic field (1 T) measured with different heating currents Iheater = 10, 15, and 20 mA at 100 K. Measurements were done for the Cr-PBA (1.4 μm)/Cr (10 nm) STE device. c VLSSE upon sweeping the applied magnetic field measured with different heating currents Iheater = 10, 15, and 20 mA at 100 K. d ΔVLSSE as a function of the estimated ΔT in a Cr-PBA film displaying a linear behavior. The obtained value of the slope is ΔVLSSE/ΔT ~ 64.9 ± 3.13 μV/K at 100 K.

The spin Seebeck coefficient (SLSSE) of our STE devices is defined as SLSSE = EISHE/∇T = (ΔVLSSE /L)/(ΔT/d), where is L the distance between voltage probes and d is the thickness of the Cr-PBA film. The estimation of the applied temperature gradient (∇T) in each layer of our STE device was done by employing the Fourier’s law () of a heat conduction. Here, we ignored the interfacial temperature drop as the interfaces are atomically contacted. The estimation of the temperature gradient on Cr-PBA may include slight uncertainty as the relative thickness of Cr-PBA is very thin compared to the interval where we measured temperature29. The unknown thermal conductivity (κ) of the Cr-PBA film was characterized by employing a differential 3ω method30,31 (Supplementary Note 2 and Supplementary Fig. 5). The estimated κ of Cr-PBA is ~2.17 ± 0.01 W/mK at 100 K, which is much lower than those of inorganic magnets. Thus, the studied molecule-based magnetic film will be effective in keeping the applied temperature gradient. Details of temperature calibration are described in Supplementary Note 2, Supplementary Figs. 6 and 7, and Supplementary Table 1. The estimated ΔT on the Cr-PBA film and measured ΔVLSSE are all directly proportional to Joule heating power ~I2 (Supplementary Fig. 8). Thus, ΔVLSSE as a function of ΔT in Cr-PBA exhibits excellent linear dependence (Fig. 2d). The obtained ΔVLSSE/ΔT is ~64.9 ± 3.13 μV/K at 100 K. Then, the SLSSE of our device was calculated to be 18.2 nV/K. Supplementary Fig. 9 shows the estimated SLSSE for the devices with several different thicknesses of Cr-PBA. Results display a general tendency of the enhancement of SLSSE with increasing thickness of Cr-PBA. In order to confirm the origin of the observed ΔVLSSE, anomalous Hall effect was also measured. Results clearly exclude the possibility of a proximity-induced ferromagnetism in the Cr layer and its contribution to ΔVLSSE (Supplementary Fig. 10).

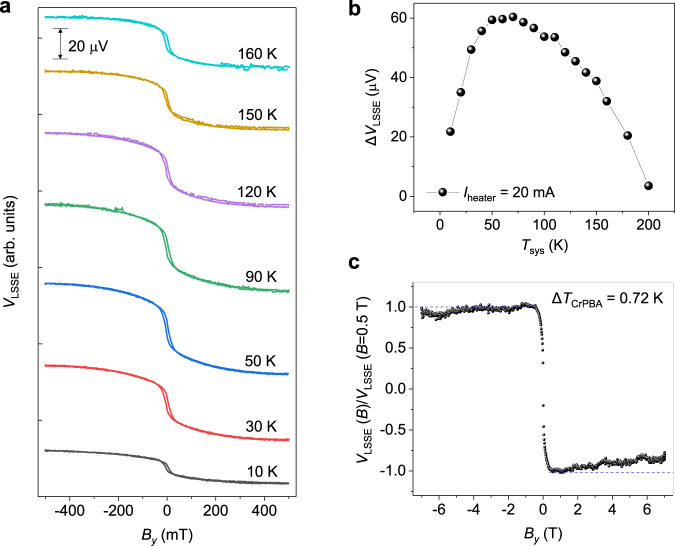

Figure 3a displays VLSSE (By) measured at various temperatures. The ΔVLSSE, defined as

Temperature- and field dependence of VLSSE.

a Temperature dependence of VLSSE measured with a Joule heating current, Iheater = 20 mA (ΔTCr-PBA = 0.72 K). Measurements were done for the Cr-PBA (1.4 μm)/Cr (10 nm) STE device with a sweeping magnetic field (By) between –0.5 and 0.5 T. VLSSE (By) curves are vertically shifted for clarity. b Temperature dependence of ΔVLSSE =

Figure 3c displays the magnetic field dependence of ΔVLSSE with applying magnetic fields up to 7 T. We note that the Nernst effect in the Cr layer produces field-dependent voltage (Vx(By)) having the same symmetry of VLSSE (see Supplementary Fig. S12a–c). Thus, we subtracted the Nernst effect from the measured Vx(By) assuming that the Nernst effect in the Cr layer is temperature independent. As the magnitude of the magnetic field increases from 0.5 to 7 T, the LSSE signal is monotonically suppressed. The ratio of ΔVLSSE change at 7 T, [(VLSSE (7 T) − VLSSE (0.5 T))/VLSSE (0.5 T)] × 100%, is calculated to be ~14%, which is similar to that observed in YIG22,28,35. Previous studies with YIG attributed the high-field suppression of VLSSE to the suppression of sub-thermal magnon28,36 (Supplementary Fig. 12d). However, the high-field suppression of the estimated VLSSE in our studies could be due to the variation in the Nernst effect because the applied ΔT could be altered at different temperature (Supplementary Note 2). The field-dependent VLSSE was also measured at different temperatures as shown in Supplementary Fig. 13. Results display no consistent tendency of the field-dependent suppression as varying system temperature. We note that the changes of resistance in the Au heater line and the Cr layer in a high magnetic field are negligible and not associated with high-field suppression of VLSSE (Supplementary Fig. 14).

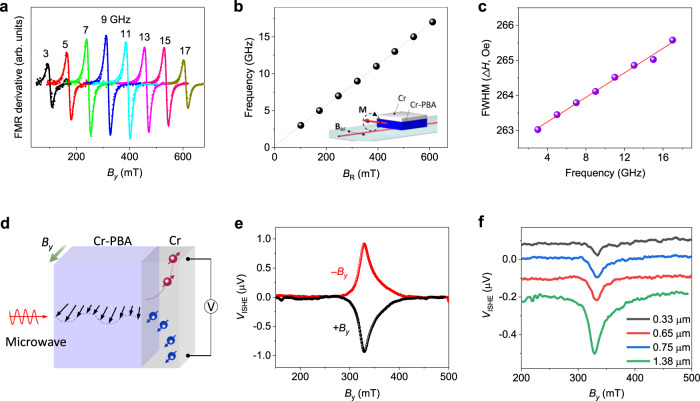

The generation, propagation, and detection of magnons in the Cr-PBA/Cr heterostructure were further studied through FMR and FMR with ISHE (FMR-ISHE) experiments. Figure 4a shows FMR spectra of a Cr-PBA (1.4 μm)/Cr (10 nm) heterojunction measured at various microwave frequencies. The frequency dependence of a resonance field (BR) shown in Fig. 4b well follows the Kittel equation,

FMR and FMR-driven ISHE results for Cr-PBA/Cr heterojunctions.

a First derivative FMR spectra of the Cr-PBA (1.4 μm)/Cr (10 nm) heterojunction at various microwave frequencies measured at 100 K. The recorded data are fitted by using the derivative of the Lorentzian function. b Frequency dependence of resonance field BR. Fitting with the Kittel equation produces Ms = 12.676 kA/m and g-factor = 1.96. c FWHM as increasing the frequency of r.f. field. The slope of a linear fit produces a low effective Gilbert damping constant, αeff ~ 7.5 × 10−4. d A schematic illustration of the spin pumping from microwave driven magnon propagation in the Cr-PBA film and its conversion into an electrical current in the Cr layer via ISHE. e VISHE(B) measured for the Cr-PBA (1.4 μm)/Cr (10 nm) bilayer upon applying 9 GHz of microwave. f VISHE(B) of Cr-PBA/Cr heterojunctions with various Cr-PBA thicknesses.

In order to investigate the conversion of spin angular momentums into an electric current at the Cr-PBA/Cr interface further, we measured FMR-driven ISHE as illustrated in Fig. 4d. The transferred spin angular momentums at the interface induce a spin current in the adjacent Cr layer. Then, the conversion from spin to charge flow via the ISHE allows electrical detection of microwave pumped magnons. Because EISHE ∝ Js × σ, a maximum magnitude of VISHE can be obtained when magnetic field B is normal to the direction of voltage probes. Figure 4e displays measured VISHE by applying continuous microwave f = 9 GHz to the Cr-PBA (1.4 μm)/Cr (10 nm) heterojunction. The FWHM and BR of VISHE are consistent with those of FMR spectra shown in Fig. 4a. VISHE reverses polarity when reversing the field direction (Fig. 4e). These behaviors clearly suggest that the observed VISHE originates from the FMR-generated magnon flow in the Cr-PBA film. As increasing d, the FMR-driven VISHE substantially increases as shown in Fig. 4f. Using the obtained

In conclusion, we introduced a new class of magnetic materials for spin caloritronics. The studied molecular magnetic film has several advantageous characteristics over inorganic magnetic insulators in terms of STE applications. Conventional electrodeposition at room temperature was successfully employed for the fabrication of the Cr-PBA-based STE device. This deposition technique can be easily adopted for the large area and mass production of thin film, which can boast an important merit of STE, that is, large-area scalability. Various other methodologies, such as painting and printing, can be also utilized for developing the PBA film. The generation and transfer of magnons are essential processes for STE energy harvesting as well as magnon information technology. Excitations of low-energy magnons in this class of magnet are much stronger than those in the typical inorganic magnets. The obtained low Gilbert damping constant, comparable to that of the epitaxial YIG film, grants transfer of thermally excited magnons over the long distance with low loss. The determined low thermal conductivity in the studied molecule-based magnetic film is an accessory benefit for STE energy harvesting because it assists in maintaining a higher temperature gradient across the film. In short, our study showed that molecule-based magnetic films could be outstanding alternatives for STE energy harvesting as well as promising platforms for the generation and transmission of magnons in various spin-based electronic applications.

For the fabrication of Cr-PBA/Cr heterojunctions, a Cr metal thin film (10 nm) for a working electrode was first deposited on a SiO2 (300 nm)/p-Si (500 μm) substrate by e-beam evaporation under the base pressure of ~7 × 10−7 Torr. The electrochemical processes were carried out using a potentiostat with a reference electrode (Ag/AgCl) and a Pt counter electrode. For a Cr-PBA deposition, the aqueous solution of 7.5 mM CrCl3·H2O and 5 mM K3[Cr(CN)6] was used. The coating of a Cr-PBA film was obtained by electrochemical reduction (at a fixed potential E = –0.88 V vs. Ag/AgCl reference electrode) of Cr3+ in an aqueous solution containing [Cr(CN)6]3− anions. The Cr2+ species formed at the surface of the Cr metal electrode react with the [Cr(CN) 6]3− developing an insoluble PBA coating. The deposition rate of the PBA film in our processing was typically ~140 nm/min. For the study of STE characterizations, the electrodepositions of PBA films were done for 10 minutes producing a thickness of 1.4 μm. The surface roughness of the Cr-PBA film was measured using atomic force microscopy (DI-3100, Veeco) and the cross-sectional image of the bilayer was investigated by normal-TEM (ZEM-2100). The crystallization of the film was probed by using a X-ray diffraction (D8 ADVANCE, Bruker AXS). The magnetic properties of the Cr-PBA film were measured by using a superconducting quantum interference device-vibrating sample magnetometer (SQUID-VSM, Quantum Design).

We used a heterojunction of Au (20 nm)/Al2O3 (130 nm)/Parylene (400 nm)/Cr-PBA (1.4 μm)/Cr (10 nm) for the characterization of LSSE in the Cr-PBA/Cr STE device. After the deposition of Cr-PBA on the Cr film, 400 nm of parylene was deposited to protect the entire sample by using a standard parylene coater (Alpha plus). For the fabrication of the studied device, the reactive ion etching was done with O2 and Cl2 gas by using a thick photoresist (AZ9660) as a protective buffer patterned for a dimension of 5 mm length and 100 μm width. After removing the buffer photoresist by acetone, the additional insulating layer of Al2O3 (130 nm) and the top Au heater (20 nm) patterned into the same dimension of Cr-PBA (5 mm length and 100 μm width) were successively deposited by e-beam evaporation.

The current source for the Joule heating was applied by using a Keithley 2636 sourcemeter. The temperature of the Au layer was estimated based on the temperature dependence of the electrical resistivity of the Au layer (Supplementary Fig. 6a). Temperature stabilization of the top Au layer depends on the heating current and usually takes less than a few minutes (Supplementary Fig. 6b). LSSE measurements were performed after the temperature of the top Au layer was sufficiently stabilized. For the measurement of the thermal conductivity of the Cr-PBA film, we used the differential 3ω method by using Keithley 6221 ac sourcemeter and SR830 Lock-in amplifier to measure harmonic ac voltage. Measurements of the thermal conductivity are further described in Supplementary Note 2. Details of temperature calibration and SSE characterization are also explained in Supplementary Note 2. Under the applied temperature gradient, the induced voltage from SSE and ISHE was measured by using a Keithley 2182 nanovoltmeter. All measurements for LSSE were performed in a Physical Property Measurement System (PPMS) (Quantum Design) with varying temperature and magnetic field.

For the FMR measurements, we used the broadband FMR of the PPMS option with a coplanar waveguide and a NanOsc Phase FMR spectrometer operated in the frequency range 2–19 GHz. For the FMR-driven ISHE measurements, we used coplanar waveguide FMR with contact pads for the detection of ISHE (KBSI and RNDWARE Co. Ltd). Devices used for FMR-ISHE studies have a channel size of 1 mm width and 2 mm length with gold contact pads at both sides. Voltages generated by FMR-ISHE were detected by using Keithley 2182 nanovoltmeter. All FMR and FMR-ISHE measurements were performed in the PPMS chamber.

The online version contains supplementary material available at 10.1038/s41467-021-21058-x.

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (2017M3A7B4049172, 2017R1A2B4008286, and 2020M3F3A2A03082444). This work was also supported by the Ulsan National Institute of Science and Technology (No. 1.200095.01). J.P. and Y.J. acknowledge the support of the National Research Council of Science & Technology (NST) grant (No. CAP-16-01-KIST) by the Korean government (MSIP). J.S. acknowledges the support of the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (2020R1C1C1011219).

I.O. and J.-W.Y. conceived the project. I.O. performed materials growth and characterization, device fabrication, and electrical measurements. I.O, J.P. and Y.J. performed FMR and FMR-ISHE experiments. I.O. and J.S. performed 3ω measurements. I.O., J.P., and J.-W.Y. did data analysis. H.J., J.J., D.C., and M.-J.J. assisted materials growth, device fabrication, and characterization. B.-C.M. assisted data analysis on FMR and FMR-ISHE results. I.O. and J.-W.Y. wrote the manuscript. All authors discussed about the results and commented on the manuscript.

The data that support the findings of this study are available from the corresponding author upon request.

The authors declare no competing interests.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.